jscherb

Expedition Leader

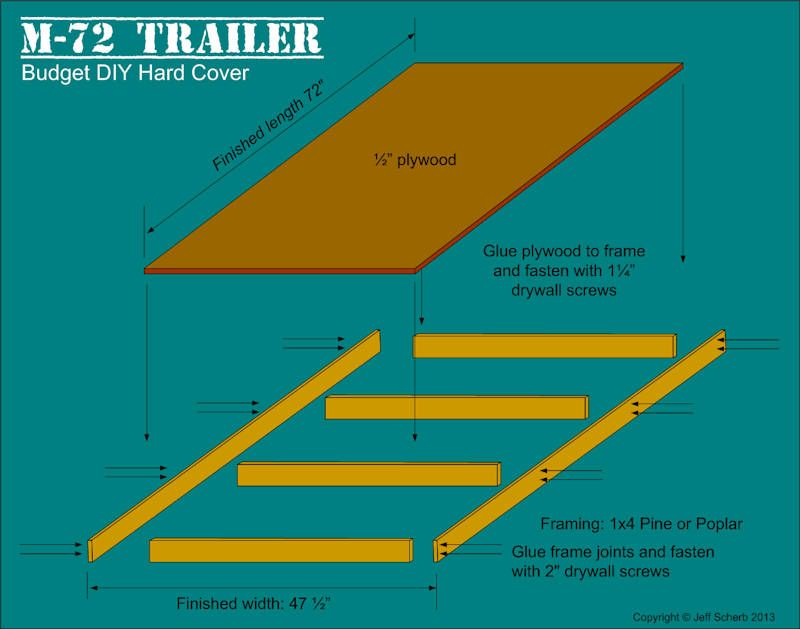

Outfitting idea: cargo rack... I've shown this photo before, you can mount rack bars to the sides with "fake rain gutters". The tonneau cover fits nicely under the rack bars.

A roof-top tent can be mounted on the bars, or you could mount a cargo rack like the one below. I don't have a set of rack bars with fake rain gutter mounts, so I just threw the rack on some quick wooden cross bars I made up for mockup purposes, without the tonneau cover:

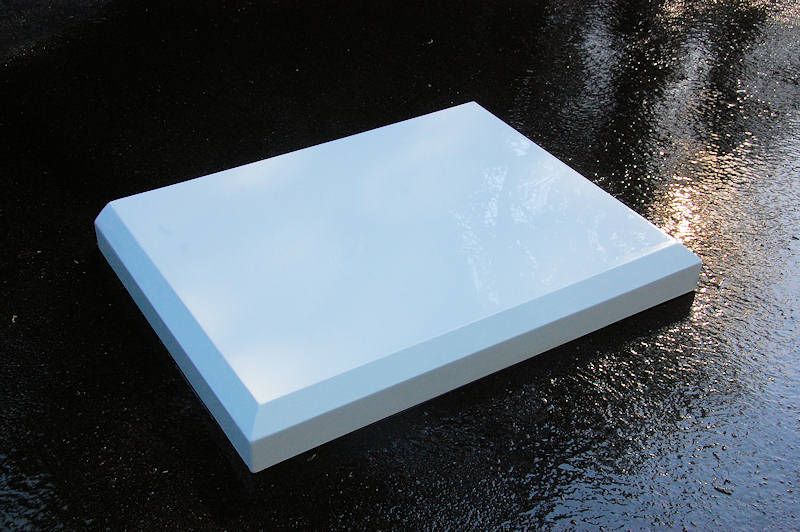

The rack could also mount directly on the fiberglass cover I'm in the process of making.

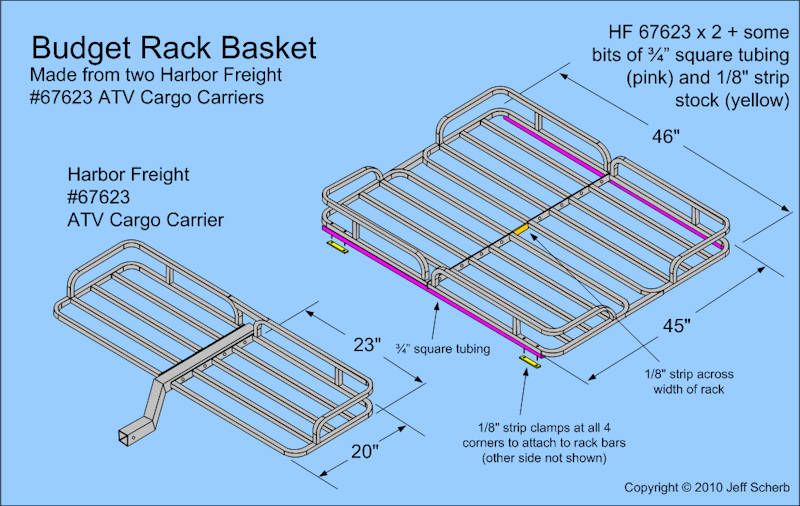

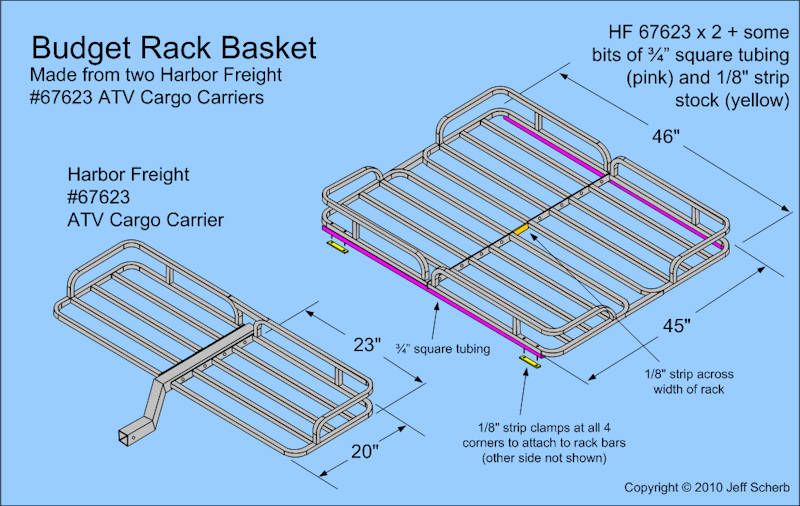

I've used this rack basket on most of my projects, it's made from Harbor Freight materials. The basic rack can be made for about $75. Here's a drawing I did when I first built the basket to put on top of my Safari Cab hardtop:

The Hi-Lift mount took less than $15 in parts from Tractor Supply. The bracket to secure the spare tire cost about the same. I can provide details for both if anyone's interested.

The rack also makes a nice place to carry long items, the "valley" in the middle makde a nice place the secure things like this 10' 2x6 (obviously you'd tie the board down, this photo is just for illustration so I didn't tie it in place).

This rack has been really handy, here are a few other places it's seen service - it's been on my Safari Cab hardtop on my Jeep through the Colorado mountains, on my prototype Dinoot Jeep-tub trailer, and on my Safari Cab-based Jeep tub camper prototype:

A roof-top tent can be mounted on the bars, or you could mount a cargo rack like the one below. I don't have a set of rack bars with fake rain gutter mounts, so I just threw the rack on some quick wooden cross bars I made up for mockup purposes, without the tonneau cover:

The rack could also mount directly on the fiberglass cover I'm in the process of making.

I've used this rack basket on most of my projects, it's made from Harbor Freight materials. The basic rack can be made for about $75. Here's a drawing I did when I first built the basket to put on top of my Safari Cab hardtop:

The Hi-Lift mount took less than $15 in parts from Tractor Supply. The bracket to secure the spare tire cost about the same. I can provide details for both if anyone's interested.

The rack also makes a nice place to carry long items, the "valley" in the middle makde a nice place the secure things like this 10' 2x6 (obviously you'd tie the board down, this photo is just for illustration so I didn't tie it in place).

This rack has been really handy, here are a few other places it's seen service - it's been on my Safari Cab hardtop on my Jeep through the Colorado mountains, on my prototype Dinoot Jeep-tub trailer, and on my Safari Cab-based Jeep tub camper prototype: