You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fiberglass M416/M100 Military-style Trailer Tub Kit

- Thread starter jscherb

- Start date

jscherb

Expedition Leader

Thank you very much!I really enjoyed reading this thread. You have great ideas and skills. Kudos to you for a job well done!

TheJosh

Explorer

I'm curious about the frame you are using. Now is this tub going to be made specifically for the harbor freight frame or will it be open for a 416 sized frame?

Ive seen the HF frame in person and its pretty cheap quality and very thin wall I couldn't imagine it being a high quality Offroad trailer base.

Ive seen the HF frame in person and its pretty cheap quality and very thin wall I couldn't imagine it being a high quality Offroad trailer base.

jscherb

Expedition Leader

I'm curious about the frame you are using. Now is this tub going to be made specifically for the harbor freight frame or will it be open for a 416 sized frame?

Ive seen the HF frame in person and its pretty cheap quality and very thin wall I couldn't imagine it being a high quality Offroad trailer base.

The whole idea behind this kit is that one should build it to their needs, so many frame choices are possible.

The tub is designed so that it can fit on the original M416 frame or any similar-sized frame (72" long x roughly 40.5" wide)

The Harbor Freight 94564 1720-lb. capacity frame is much stronger than the rest of the Harbor Freight line, especially if you modify it as I did and strengthen it with a center backbone...

Detailed plans and instructions for that conversion begin here: http://tventuring.com/trailerforum/thread-119-post-2158.html#pid2158.

I also am told that the company that's most likely to bring this tub kit to market will also offer a welded frame option for it.

You could also weld the HF frame together instead of bolting it.

There are lots of frame options depending on what your needs are.

jscherb

Expedition Leader

I found a couple of original military trailers on sale on eBay this week, and the photos were similar angles to ones I took of this project, so I did up a comparison:

My project has Jeep-sized tires which are larger and wider than the tires on the original trailers, so I've got wider fenders in both the M100 and M416 styles to cover those tires. Another difference you can spot is the lip on the tub projects outward on the original tub, on mine it projects inward - I did this to make the outside look nicer, to provide for internal clamping points for things like the tonneau cover, and to keep the overall width of the tub just under 48" so a hard cover could be DIY-built from a single sheet of plywood. One other small difference is that the fiberglass tub is almost 2" taller to increase the cargo capacity below the top rim of the tub (and below any hard covers that might go on there).

My project has Jeep-sized tires which are larger and wider than the tires on the original trailers, so I've got wider fenders in both the M100 and M416 styles to cover those tires. Another difference you can spot is the lip on the tub projects outward on the original tub, on mine it projects inward - I did this to make the outside look nicer, to provide for internal clamping points for things like the tonneau cover, and to keep the overall width of the tub just under 48" so a hard cover could be DIY-built from a single sheet of plywood. One other small difference is that the fiberglass tub is almost 2" taller to increase the cargo capacity below the top rim of the tub (and below any hard covers that might go on there).

Mark Harley

Expedition Leader

Looks great..........and no need for a trip to the sand blaster.

jscherb

Expedition Leader

Looks great..........and no need for a trip to the sand blaster.

It is sooooo nice dealing with all new parts rather than trying to restore some rusty, dented old thing. And the fiberglass parts will never rust

jscherb

Expedition Leader

Do you have the specifics on that cargo box from walmart?

I just checked the Walmart web site and couldn't find it there. It's a Contico Xtreme Tuff SUV storage box with lock. Dimensions are 35x14x13h and it's model # 3514BK-1. Here's a version of it at Lowes, but this version doesn't have the the integrated lock: http://www.lowes.com/pd_207123-230-3514_0__.

jscherb

Expedition Leader

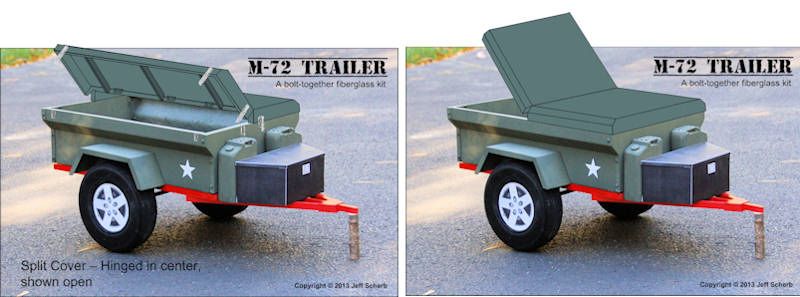

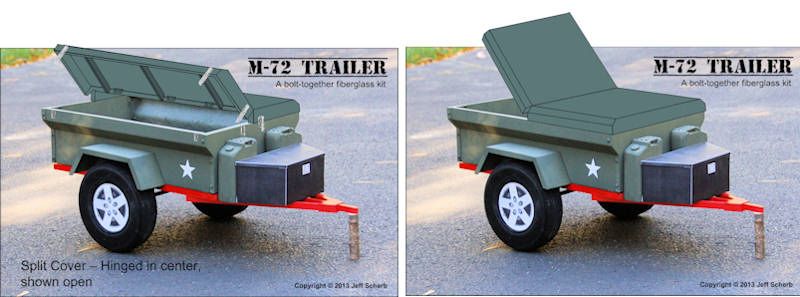

Earlier in this thread I posted a number of designs for a fiberglass hard cover for this tub, and now that I've finished the construction on the basic tub and trailer, it's time to finalize the design for that cover. I won't repeat all of the design drawings here, in this post I'll show one design - please give me your input on whether you think this is the design I should go with or not.

I plan to mold the cover in two halves. There are two reasons for that - first, in the event the cover becomes a commercial product, it's to make the cover parts small enough to ship UPS Ground rather than the much more expensive truck freight. And, the two halves could be installed in several configurations.

They could be bolted together into a one-piece cover. When closed, the cover would look like this:

The line across the cover shows where the two halves would meet, so it would be split crosswise. The front and back of the cover are angled, that angle matches the angle on the sides of the cover - most other covers I've seen have vertical edges in the front and back without the angles.

If the two halves were bolted together to make a one-piece cover, it could be hinged on the either side or on one of the ends, in the side-hinged configuration, it could open like this:

The cover could be supported in the open position with gas struts, or a simple prop stick. Ignore the bracing on the underside of the cover for now, there will be some bracing there, but that's not the final design.

Rack bars could be installed on the cover. In the illustration below I've put rack bars on the M48, which is the 48" version of the tub. I've also draw it with hinges on the front edge - in this drawing the cover halves are bolted together into a one-piece cover and the cover opens at the back.

The other way the cover could be installed would be to have it hinge in the middle, and open like this:

Both the front and the back would open, although not at the same time - when one side is opened, the other side would stay latched.

The cover would be reinforced so that a cargo rack basket could be installed; in the case of bolting it together to make a one-piece cover, the rack could be the full length of the cover. In the case where it was hinged to open in halves, a rack perhaps could be installed on one half, or two small racks, one on each half.

The reinforcements in the cover would be such that when bolted together as a one-piece cover, it would be strong enough to support a tent:

The illustations above show the cover split crosswise; the other option I was considering was to split it lengthwise. Both are shown below for comparison:

I'd appreciate it if you guys could comment on the following:

1. Is there a reason the lengthwise split between the two halves would be preferable to the crosswise split? If you think the lengthwise split would be preferable, please let me know why.

2. Styling: I've drawn the cover with the angle on the sides also across the front and the back. Many covers have simple vertical ends. What do you think of the angled ends? Do they matter one way or the other?

Thanks in advance for your input.

I plan to mold the cover in two halves. There are two reasons for that - first, in the event the cover becomes a commercial product, it's to make the cover parts small enough to ship UPS Ground rather than the much more expensive truck freight. And, the two halves could be installed in several configurations.

They could be bolted together into a one-piece cover. When closed, the cover would look like this:

The line across the cover shows where the two halves would meet, so it would be split crosswise. The front and back of the cover are angled, that angle matches the angle on the sides of the cover - most other covers I've seen have vertical edges in the front and back without the angles.

If the two halves were bolted together to make a one-piece cover, it could be hinged on the either side or on one of the ends, in the side-hinged configuration, it could open like this:

The cover could be supported in the open position with gas struts, or a simple prop stick. Ignore the bracing on the underside of the cover for now, there will be some bracing there, but that's not the final design.

Rack bars could be installed on the cover. In the illustration below I've put rack bars on the M48, which is the 48" version of the tub. I've also draw it with hinges on the front edge - in this drawing the cover halves are bolted together into a one-piece cover and the cover opens at the back.

The other way the cover could be installed would be to have it hinge in the middle, and open like this:

Both the front and the back would open, although not at the same time - when one side is opened, the other side would stay latched.

The cover would be reinforced so that a cargo rack basket could be installed; in the case of bolting it together to make a one-piece cover, the rack could be the full length of the cover. In the case where it was hinged to open in halves, a rack perhaps could be installed on one half, or two small racks, one on each half.

The reinforcements in the cover would be such that when bolted together as a one-piece cover, it would be strong enough to support a tent:

The illustations above show the cover split crosswise; the other option I was considering was to split it lengthwise. Both are shown below for comparison:

I'd appreciate it if you guys could comment on the following:

1. Is there a reason the lengthwise split between the two halves would be preferable to the crosswise split? If you think the lengthwise split would be preferable, please let me know why.

2. Styling: I've drawn the cover with the angle on the sides also across the front and the back. Many covers have simple vertical ends. What do you think of the angled ends? Do they matter one way or the other?

Thanks in advance for your input.

I think the cross split would be much more marketable than the lengthwise split due to its versatility - solid lid or various hinge locations, as you illustrated. Also, the main concern I'd have with the lengthwise split is what size of items would you typically be lifting in and out of the trailer, and would they easily fit through the 1/2 lid opening split lengthwise? Cooler? Box of wood? Plastic bins?

Having said that, the one benefit of the lengthwise split might be the ability to use your lid on a wider trailer. I'm close to completing a 6' x 4.5' trailer and the lid will be 1"x1" steel frame and steel sheet. If your lid were available and I could adapt it to my trailer, depending on cost, I'd consider it. I could envision adding a filler piece of wood and glass layer between each half of your lid to widen it to 54", and attach each half lid flange to that filler piece. With a crosswise split, it would require cutting each lid half in half and I'm not sure that would be structurally feasible. But I don't know what the market for a lid to fit a wider trailer is. Most of these lids would be sold for your trailer or existing M416's I think.

The beveled front and rear part of the lid just make it look sleeker. I probably prefer the sleeker look but not if it adds much to the cost - the "traditional" lid shape would do just fine. How much time/cost might the beveled edge add to fabrication or finish work? Will the lid come pre-finished, or ready to finish?

Having said that, the one benefit of the lengthwise split might be the ability to use your lid on a wider trailer. I'm close to completing a 6' x 4.5' trailer and the lid will be 1"x1" steel frame and steel sheet. If your lid were available and I could adapt it to my trailer, depending on cost, I'd consider it. I could envision adding a filler piece of wood and glass layer between each half of your lid to widen it to 54", and attach each half lid flange to that filler piece. With a crosswise split, it would require cutting each lid half in half and I'm not sure that would be structurally feasible. But I don't know what the market for a lid to fit a wider trailer is. Most of these lids would be sold for your trailer or existing M416's I think.

The beveled front and rear part of the lid just make it look sleeker. I probably prefer the sleeker look but not if it adds much to the cost - the "traditional" lid shape would do just fine. How much time/cost might the beveled edge add to fabrication or finish work? Will the lid come pre-finished, or ready to finish?

jscherb

Expedition Leader

I think the cross split would be much more marketable than the lengthwise split due to its versatility - solid lid or various hinge locations, as you illustrated. Also, the main concern I'd have with the lengthwise split is what size of items would you typically be lifting in and out of the trailer, and would they easily fit through the 1/2 lid opening split lengthwise? Cooler? Box of wood? Plastic bins?

Having said that, the one benefit of the lengthwise split might be the ability to use your lid on a wider trailer. I'm close to completing a 6' x 4.5' trailer and the lid will be 1"x1" steel frame and steel sheet. If your lid were available and I could adapt it to my trailer, depending on cost, I'd consider it. I could envision adding a filler piece of wood and glass layer between each half of your lid to widen it to 54", and attach each half lid flange to that filler piece. With a crosswise split, it would require cutting each lid half in half and I'm not sure that would be structurally feasible. But I don't know what the market for a lid to fit a wider trailer is. Most of these lids would be sold for your trailer or existing M416's I think.

The beveled front and rear part of the lid just make it look sleeker. I probably prefer the sleeker look but not if it adds much to the cost - the "traditional" lid shape would do just fine. How much time/cost might the beveled edge add to fabrication or finish work? Will the lid come pre-finished, or ready to finish?

Thanks for the comments!

The target for this cover is of course this fiberglass tub kit and the original M416's and M100's (and maybe some of the aftermarket military look-alike off-road trailers?). I'm not sure there are enough custom wider trailers out there to make it worthwhile to alter the design to a lengthwise split to accommodate them - if the benefits of a crosswise split for the target trailers make it the way to go, I don't think the few possible custom wider trailers out there would swing the decision the other way.

The beveled front and rear edges wouldn't add much to the cost, if anything. If this cover were to be product in metal, the beveled front and rear would likely add some fabrication time, but in fiberglass there would be very little extra time, if any, required. I'll have to wait until the production time and cost estimates are done by the company that would market this to know for sure.

My guess is this would be offered in either white UV-stable gel coat, or in black paint-ready gel coat. The white would be paintable too, but you wouldn't have to paint it to get UV protection. I'd like to see the tub kit and the cover offered in olive drab gel coat as well, but I don't know if there would be enough interest in buying it in olive drab to make the minimum investment in that color custom gel coat worthwhile.

Similar threads

- Replies

- 0

- Views

- 354

- Replies

- 2

- Views

- 837

- Replies

- 0

- Views

- 390

- Replies

- 4

- Views

- 1K