ebrabaek

Adventurer

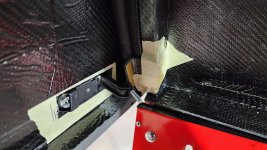

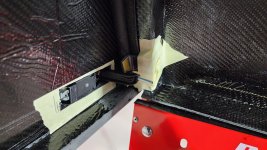

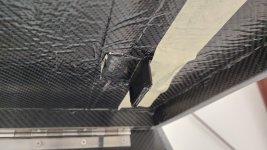

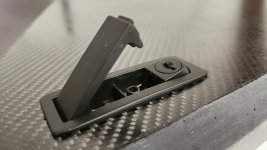

It was however time for the hardware for the gas struts and latch striker plates. Onwards to hardware fabbing. There are again so many different ways to do this. Mine no better that anyone else's.

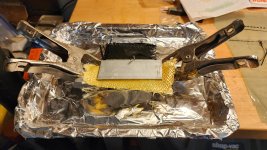

We switch gears and please let me introduce you to Max Bond HTE. It is an epoxy that requires post heat cure. I build a couple of big adventure bike's mufflers with it and its incredible stable to almost 500 deg. F. BUT, it has to be cured after the layup. That does present a few issues. I cure mine at 300 degF for 60 minutes. Cant use anything other than metal. Clamps, tape, etc.

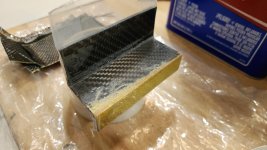

First the bracketry.... Treated with release agent.

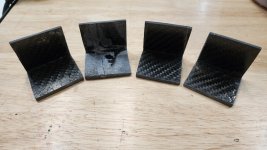

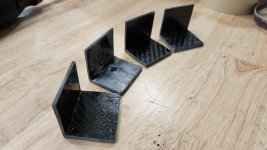

I need to make two 90's with 1 inch in between. 8 layers of 5.7 oz 6K and 2 layer's of K-39 Aramid. This is for the latch striker plates. Again, it will make more sense when you see it in place. The Aramid is in the place for the striker pin of the latch to ensure it does not wear through the Carbon.

Then Max bond HTE was mixed and is now being elevated to 120 degF while de gassing a bit. It is thick and impossible not to stir in bubbles while mixing.

Then the layup begins. I tend to lay it all up and then folding it over the "mold"

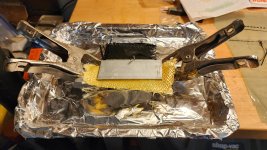

Then held in place with clamps....

Then in the oven ramping it up.

We switch gears and please let me introduce you to Max Bond HTE. It is an epoxy that requires post heat cure. I build a couple of big adventure bike's mufflers with it and its incredible stable to almost 500 deg. F. BUT, it has to be cured after the layup. That does present a few issues. I cure mine at 300 degF for 60 minutes. Cant use anything other than metal. Clamps, tape, etc.

First the bracketry.... Treated with release agent.

I need to make two 90's with 1 inch in between. 8 layers of 5.7 oz 6K and 2 layer's of K-39 Aramid. This is for the latch striker plates. Again, it will make more sense when you see it in place. The Aramid is in the place for the striker pin of the latch to ensure it does not wear through the Carbon.

Then Max bond HTE was mixed and is now being elevated to 120 degF while de gassing a bit. It is thick and impossible not to stir in bubbles while mixing.

Then the layup begins. I tend to lay it all up and then folding it over the "mold"

Then held in place with clamps....

Then in the oven ramping it up.