The "Home Depot" DIY Overhead Cargo Net

Here's an inexpensive way to DIY an overhead cargo net that I think is better than anything that's on the market. I'll call it the Home Depot Overhead Cargo Net because the main supplies necessary to make it can be found at Home Depot. All it takes is a few ratchet straps (Home Depot, $1.75 each:

https://www.homedepot.com/p/Husky-15-ft-x-1-in-Ratchet-Tie-Down-Strap-with-S-Hook-FH0867/312994491), some heavy-duty "pet resistant" screen (Home Depot, $15.64

https://www.homedepot.com/p/Saint-G...Roll-for-Windows-and-Door-FCS8988-M/100397140) and a little bit of sewing.

With some gear (3 bags):

It's plenty strong enough to hold my half door uppers:

I think it's better than anything you can buy commercially because:

- It's more rigid than anything on the market because it uses ratchet straps to tension it; it won't sag down as much as other nets because it can be made tighter with the ratchet straps.

- The heavy-duty screen makes it easier to store random and smaller items up there without them slipping through the webbing.

- It costs about $20 to make.

I made one for my LJ but the steps would be the same for any Jeep so here are the details...

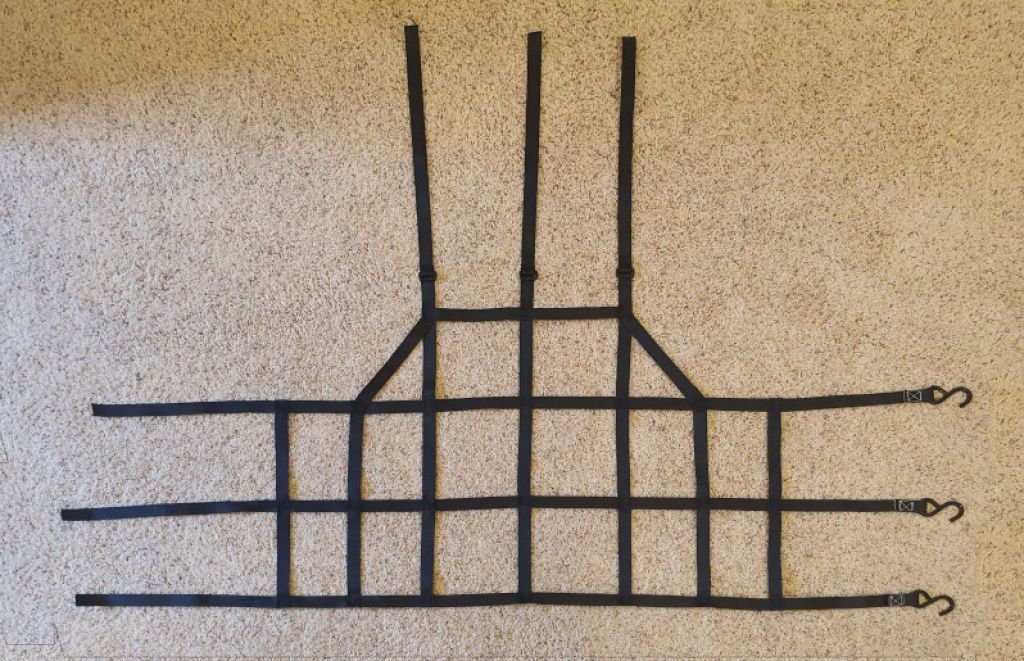

The first step is to make the cross-straps. These are the ones that will be tightened with the ratchets. In this photo, I've got three straps across, about 8" apart. I haven't cut the excess off yet so that's hanging down.

To keep the ratchets out of the way of cargo in the net, I installed them like this:

It was necessary to shorten the tail end of the ratchet end of the straps so they fit properly around the roll bar - in this next photo an unmodified strap and a shortened one are on my sewing machine table:

Shortening them is simple - cut the sewed loop off the ratchet, loop the cut-off strap end around the pin on the end of the ratchet and resew. Depending on the diameter of the roll bars in your model Jeep, you might need a different length so check this before you sew.

The next step is to add the longitudinal webbing. Cutting the excess off the cross-straps already installed provides plenty of webbing for this step. Leave the cross-straps in place after cutting off the excess; the longitudinal straps will be placed on them and temporarily stapled to the cross straps.

In this photo I've added 5 longitudinal straps. They're also spaced about 8" apart. Several are a bit longer in the front to go around the main hoop of the roll bar. I've left the ends of all the straps a bit long, I'll trim them after I sew them to the cross straps.

Clothespins can be used to position the straps for stapling, this is a work-in-progress photo:

At every place where the straps cross, staple the straps together. Two staples at each location will hold them for sewing.

All crosspoints stapled:

Once all the straps are placed and stapled, remove the assembly from the roll bars, sew every place where the straps cross and pull out the staples. The ends of the straps can be trimmed if you left them long when you stapled them as I did. Sewn and trimmed:

BTW the best way to shorten the straps is to cut them with a hotknife, this melts the end so it won't fray. since most people won't have a hotknife you can cut them with scissors and run a hot soldering iron across the cut end, or even a match can be used (carefully). Trimming the ends with a hot knife:

Next step: adding the screen. Lay the sewn net out on the floor and cut a piece of the screen to fit. Staple it around the edges to hold it in place for sewing.

Sew the perimeter of the screen to the webbing and then sew the screen to each cross-strap and longitudinal strap.

To secure the longitudinal webbing to the roll bar main hoop, I added a strap loop and some velcro.

Additional details could be added as desired or needed, for example straps on top of the net to hold cargo in place.

This net cost me $22.56 (which includes the sales tax); the velcro and strap loops for the main hoop attachment I had on hand but wouldn't cost more than a few dollars if they weren't in my sewing supplies drawer. So for just over $20 I now have an overhead cargo net that's better than anything I could buy. It's an easy sewing project, something that a beginner with a sewing machine could easily do.

BTW the same technique can be used to make a bikini top. Might use some fabric other than the netting to provide more shade, and you'd install it on top of the roll bars instead of the bottom, but mostly it would be the same.

.jpg)