In 2020 I designed and built a prop for the MORryde TJ HD tailgate hinges to hold the tailgate open:

It's been in use on my LJ since then and works very well:

Since the trailer is a camper and the rear door will be used for access to the interior, it wouldn't do to have the door slam shut with someone inside so I made another tailgate prop. In this post I'll show most of how I made it; I didn't take photos of every detail but I hope there's enough info here that someone could follow along and make one.

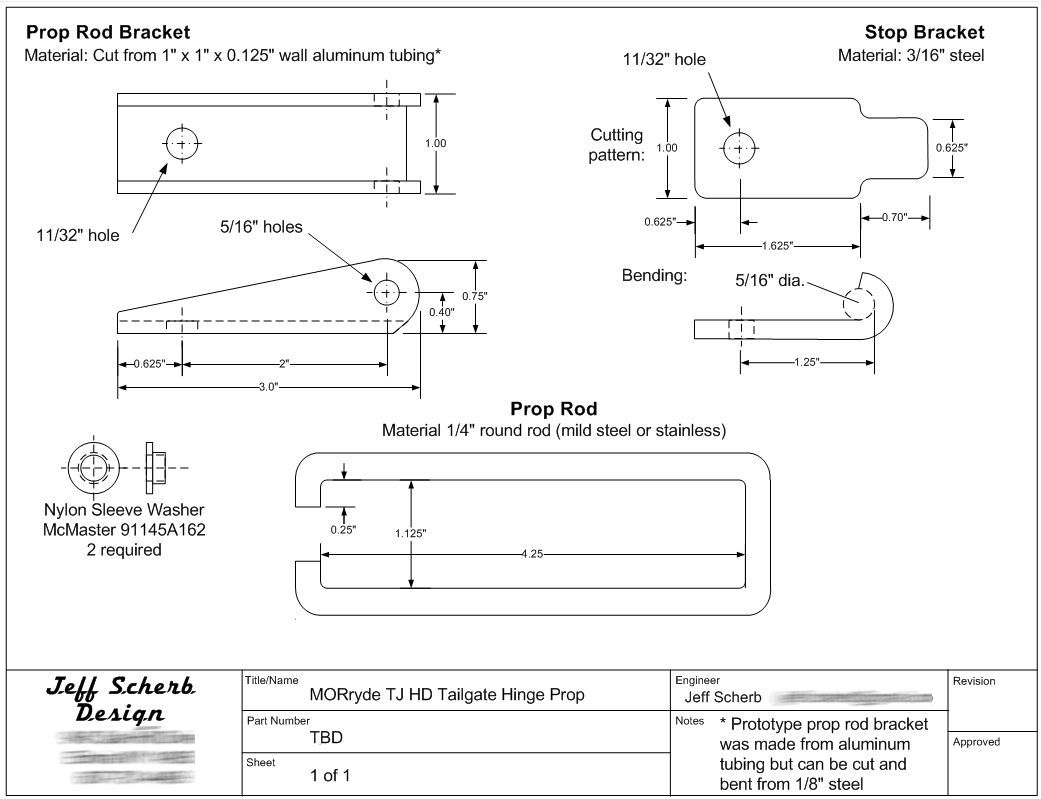

The parts:

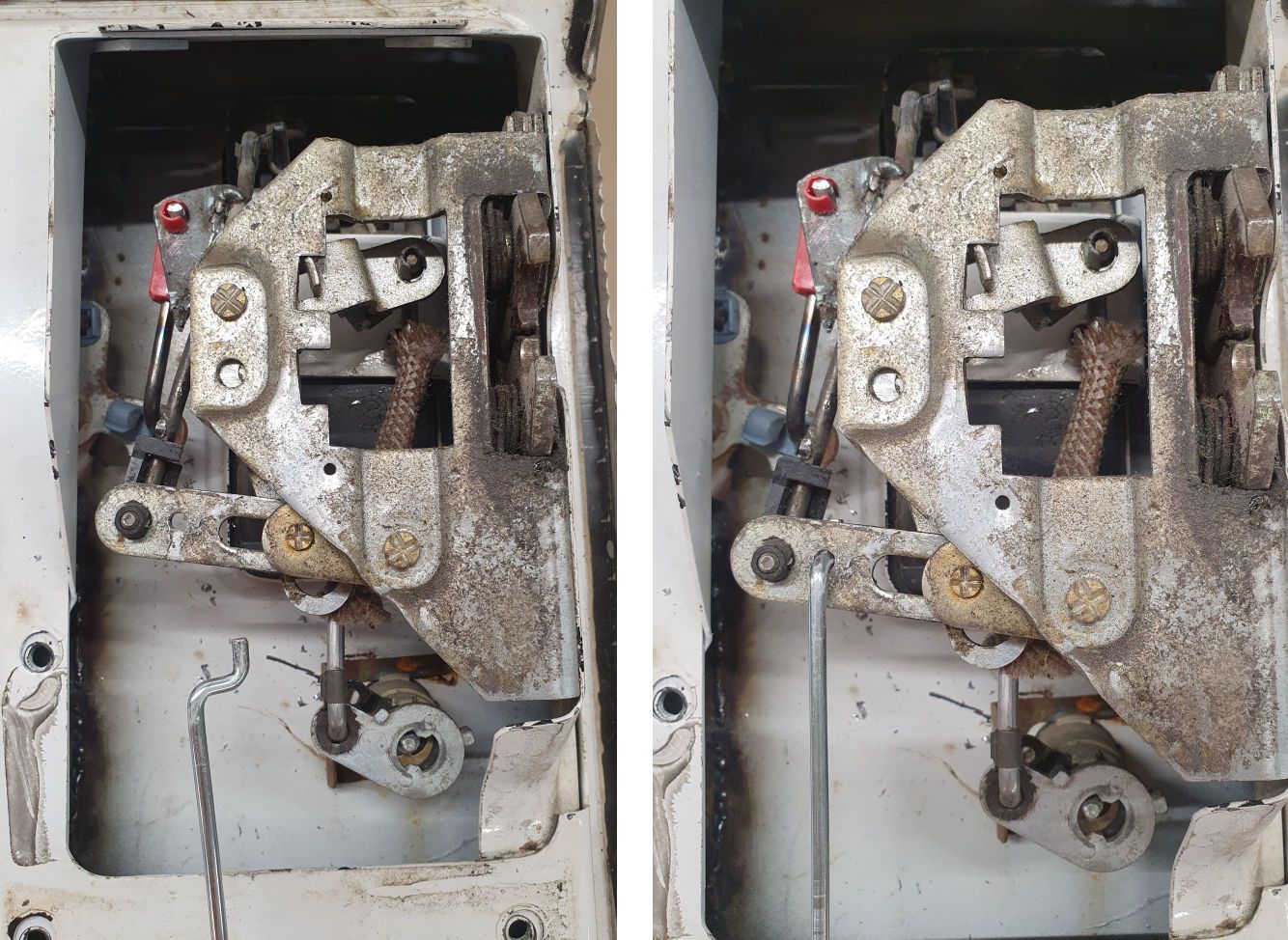

To make parts accurately, I typically cut the part image from the drawing and affix it to the metal stock with rubber cement. I've done that in this next photo; the stock is 1" square aluminum tubing:

In the above photo I'm center punching the hole for the prop rod, I typically mark and drill the holes before cutting out the part because it's easier to drill a large piece of stock than a small part. This next photo shows the part above after drilling, cutting and a little filing and sanding to clean it up. The bushings for the prop rod are in place:

Next I'm making the Stop Bracket. Bending is accomplished in a vise, using the shank of a drill as an anvil to create a nice bend.

The prop rod is bent from 1/4" steel rod. For the one on the LJ, I used stainless rod but I didn't have any stainless on hand so this one is mild steel and I'll paint it to prevent rust. The bending is done in a vise with a hammer and I heated each bend with a propane torch before bending to make it easier to bend. I used various size scrap pieces of metal clamped in the vise along with the rod to create the bends accurately. Bending the rod accurately is the most difficult part of this project.

Once the rod is bent, it's test fit in the prop rod bracket and adjusted as necessary. I needed to file a little off the inside corners of the bends that go into the bushings in order for the prop rod to seat close enough to the prop rod bracket.

The MORryde hinges are laser cut from rectangular tubing and they've got a weld seam inside from the manufacturing process for the tubing. I used a rat tail file to make a groove in the back of the prop rod bracket so it sits nicely over the weld.

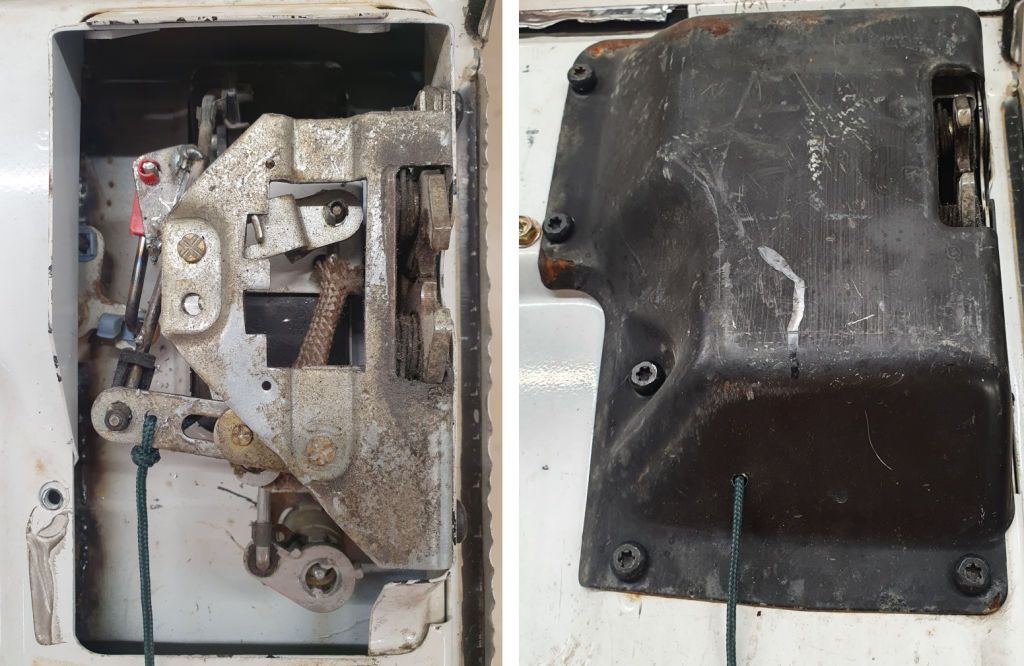

All of the parts test fit in a hinge:

After painting the prop rod, one last detail - I slipped some heat shrink tubing over a couple of places on the prop rod where metal-on-metal contact could happen and possibly scratch the paint. Then I installed the assembly in the hinge on the trailer:

I mentioned that bending the prop rod is the most difficult part of the project - the 4 bends must be equal and parallel. There is a simpler way to make the prop rod with only two bends; it won't be quite as strong but it's easier to make:

Next I need to make an inside release for the tailgate latch. After sleeping in the camper it would be good to be able to unlatch and open the rear door from the inside. I've done two designs for an inside release and I'll show both, stay tuned...

.jpg)

.jpg)

.jpg)

.jpg)