Bike ramp

PM from Vic:

Hi Doug,

I'm busy here in Florida working on my camper. Not sure if you've seen my build page, but there was lots of wood rot so it needed a major rebuild.

I'm about to start building the bike garage and would appreciate your advice on a couple of things. I'm hoping to get a Honda CRF230L dual sport if I can find a used one for a decent price, but haven't seen many available. There are quite a few of the off road version available but not the dual sport. Did you do the conversion on your 150s to make them street legal, or did you buy them that way someplace? I've seen kits for $500 or $600, but not sure how much trouble it is to get them registered.

I was using my bicycle today as a model for the motorcycle, to visualize the layout. My plan was to use the door as the ramp, but the door is only 4 feet high, so will need some kind of an extension to keep the angle gentle enough. It looks like a 6-7 foot ramp would be OK but I'm not sure. The 230 weighs 267 lbs so I'm sure it could be a bit of a challenge to balance the bike and get it up the ramp. I'm guessing that it's possible to "walk" it up, but using the bike in 1st gear so you don't have to push it?

Any advice or ideas from your experience would be greatly appreciated, either here, or if you want to post it on my build thread on the Mitsubishi truck for the benefit of all.

Thanks much,

Vic

I'm responding here in Vic's build thread so others can share in this.

First, apologies for not being around ExPo much lately. I've been consumed by other things and have just not had the bandwidth to contribute.

As to the bike ramps:

The 230 is a great choice. It's basically the same bike as our 150s with a bigger bore/stroke (not sure which or if both) and bigger wheels.

You can buy the lighting kits from Baja Designs. Highly recommended and it's not just because we know the owners. They really do make the top quality gear for that purpose. I've used their kits on every dirt bike I've ever kitted for the street and have never had a single issue.

Our stock armatures on the 150s are not really up to pulling the lighting kit. I recommend you have your stator rewound to generate more amperage. It's inexpensive and quick. Baja Designs can do this for you.

As to the ramp, We used a door that opened up (top edge hinge) and a folding aluminum bike ramp. We stowed the bike ramp on the rear wall of the garage.

One advantage of a top hinged door was that it formed a wonderful rain and shade shelter for working around the garage and for loading / unloading.

I'm sure a creative fabricator could create a downward opening door that could craftily integrate a folding extension to make a long enough ramp to load/unload the bike.

I don't have it handy to measure, but I think our ramp was about six feet / 1.8 meters. It was the shortest we could use and deal with our load height.

I used first gear and walked the bikes up into the truck. I stepped up onto a motorcross milk crate as I walked the bike in.

The embarassing part is that until we deleted a bunch of the stuff we had in the garage, it took me longer to remove and stow all the stuff we had shoved into the garage than it took to unload or load the bikes. The bikes really went in and out very easily and quickly.

There are extensive collections of photos of our buildup that show the details on the garage construction, the bike clamps, etc. here:

http://www.hackneys.com/mitsu/index-buildup-photos.htm

There are garage shots throughout, but I did the finish work on it as one of the last steps in the build. You'll start to see quite a bit of garage stuff in these late albums:

http://www.hackneys.com/mitsu/photos/buildup_album_23/index.htm

http://www.hackneys.com/mitsu/photos/buildup_album_24/index.htm

This album has the detail on the system I used to clamp the shovels, pick, ax, bike ramp, etc. in the garage:

http://www.hackneys.com/mitsu/photos/buildup_album_25/index.htm

This album has the detail on how I sealed the garage door top hinge from rain:

http://www.hackneys.com/mitsu/photos/buildup_album_26/index.htm

Garage and top hinge door:

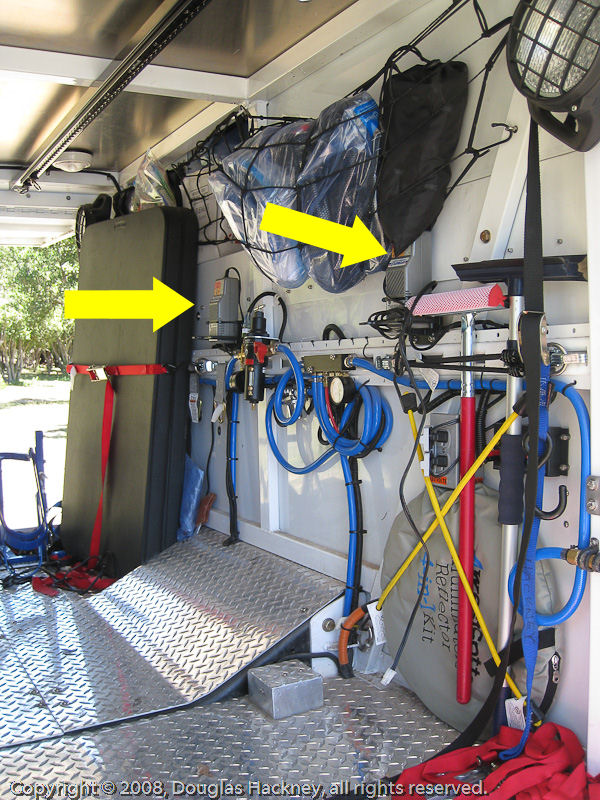

Air regulator, lines and forward garage wall stowage. Note the two battery chargers for the electric start 150s. The 150 motors are made in Brazil, so I was hopeful I could find a kick-start 150 down there and put kick start kits onto our bikes. I never pursued this idea once we were in South America.

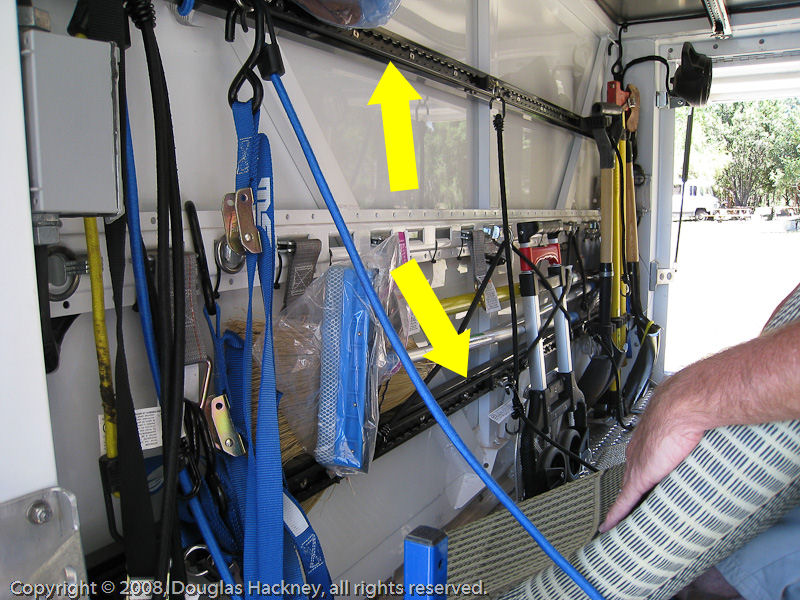

Aft garage wall stowage. The aluminum rails with adjustable anchor points were extremely useful and highly recommended.

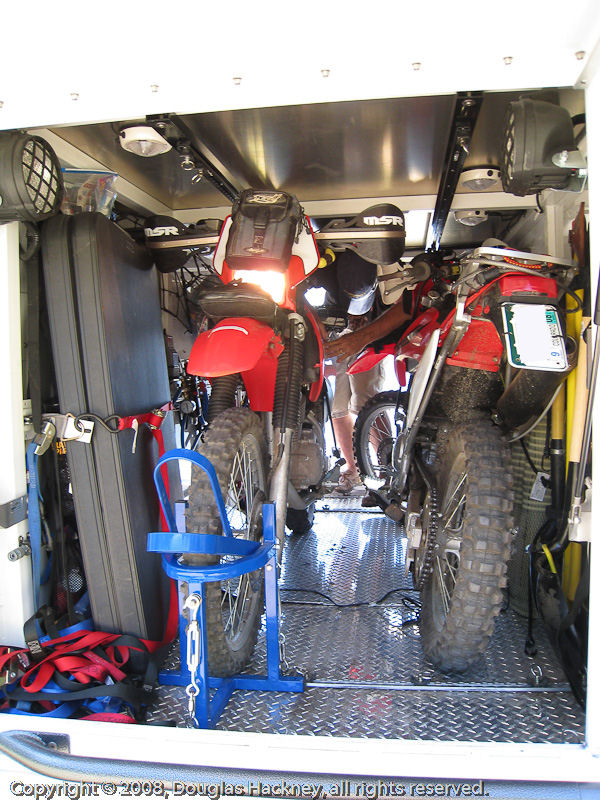

Loading Steph's bike. I'm just ready to step up on the motocross milk crate and power the bike on into the garage. The load was very easy and quick once I worked out the order and arrangement of things. Your 230 may be an inch or two taller than our 150s.

Loading my bike. Note that we loaded from each side of the truck. The bikes always went in nose first and unloaded tail first.

My 150 nosed up into the clamp. The bike clamps worked very well. They are vastly superior to a simple stop and using tie downs on the bars. Plus, they prevent the fork springs from being compressed while the bike is stored.

I built the clamps to mount onto adjustable aluminum rails so we could reconfigure the entire garage at will. We never moved them the entire two years.

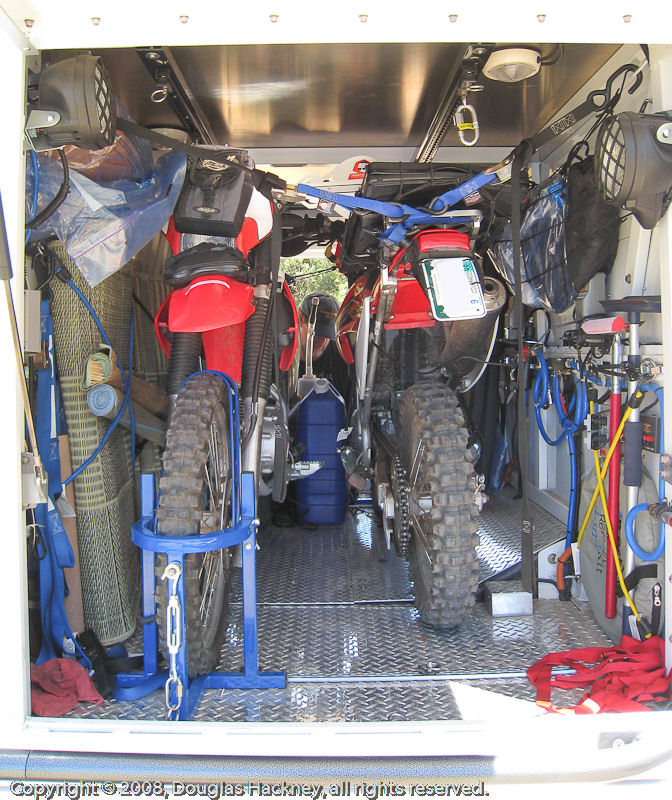

Shot from passenger side of the truck, both bikes clamped down and tied off. Note that the rear of the bike is held in place with no downward compression of the spring/shock. BTW, the rear racks on our bikes were made for the 230s but bolted right onto the 150s since they are the same frame, motor, etc.

Shot from the driver's side of the truck showing where we stowed the folding ramp. Note that I'm in the shade and I'd also be dry if it was raining. The top hinge doors do have some advantages.