You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Land Rover ideas for Jeeps

- Thread starter jscherb

- Start date

rnArmy

Adventurer

Hey Paul,

Thanks, I've been wondering if people are finding this info interesting or useful. I'm just getting started, lots more ideas to come if people are interested. I've got a huge stack of these magazines and almost every one has something in it that as a Jeep person I find interesting.

When companies like Bulldawg make molds, they usually make the window mounting surface flat so they can install flat glass (or RV-style windows or hatches). That's what Bulldawg has done so they can easily and affordably offer slider windows or cargo hatches. Unfortunately the TJ factory hardtop window mounting surface is curved in both directions, which means that simple solutions like installing an RV-style slider or hatch won't work, and either a curved window is necessary (expensive custom window frame/manufacturing tooling) or some sort of "adapter" (which I called a "retrofit kit" in my earlier post) is necessary which mounts to the curved window mounting surface and provides a flat mounting surface for an affordable window or hatch.

For the JK/JKU and JL/JLU the design of the hardtop allowed me to come up with a fairly simple laser-cut aluminum retrofit kit to allow inexpensive RV-style windows to be installed. Unfortunately due to the way the TJ/LJ window openings curve, an aluminum retrofit kit wouldn't be simple and would probably require custom tooling to produce.

The design I've done for the TJ and LJ uses a fiberglass retrofit kit, which is easy to make, even for a one-off project, but it would be more expensive to produce than the JK/JL retrofit kits. But I just don't think there would be enough demand - I mean, look at your decision Paul, you decided that for the reasonable upcharge the cargo windows would involve and the fact that it would come installed from the factory it still wouldn't be worthwhile for you to have them (I'm not criticizing you, just using you as an example of someone for whom having cargo windows would be easy and you decided it wasn't worth it).

Yes - I did consider the side opening windows, and then opted not to get them. And they were reasonably priced. The reasons I didn't go with them:

1. I just didn't think I'd use them enough. There's really nothing I can't reach from the tailgate end (even with the drop-down tailgate). There's been only a few times I wished I had them, and that was only when I was feeling lazy and wishing I didn't have to swing the spare tire carrier to the side, open the back window, and then possibly have to drop the tailgate (all this literally takes just seconds) to get whatever I needed from the back.

2. I was concerned they may leak (over time).

3. I was mildly concerned the latches to open the windows might catch on something when I'm out four-wheeling and get damaged (a distant concern). My fender flares stick out way more than the latches would though.

4. I was concerned they may be easily popped open by someone with ill intent, and they could gain access to the inside of the Jeep. Sometimes there may-or-may not be guns back there when overlanding.

Now if the side "windows" were the opening to a storage unit built into the top (like in some of the pictures posted previously), then I might have been more interested. That would be more practical, as usable storage space is an issue in the TJs (that's why I have a little trailer), and the space above the wheel wells is kinda wasted.

One option I did get from Bulldawg was their rear window defroster. I've had the hardtop now a little over three years, and have used it... once. Now if the Jeep wasn't kept in the shop when not in use, and was my daily driver... then the rear defroster might get used more. I think a better option (which they don't offer) would be a rear window wiper. I did get their battery roof light for inside, and that was worth every penny - it gets used a lot when overlanding.

Last edited:

jscherb

Expedition Leader

Magnetic Screens

This isn't a product listing, it's more of a short "how to" article.

It appears he's just using magnetic strips to hold loose window screen in place. I did a similar thing a few years back but I sandwiched the edge of the screen between the magnetic strip and webbing and sewed everything together. Also he put the screen on the inside, I put mine on the outside.

From the inside:

They can be rolled up for storage:

The magnetic strips do a good job at holding them in place - I ran around town with the window open and the screen in place, topping out at around 50mph and had no problem with the screen staying in place, although screens do make some wind noise at speed. They'd probably stay in place at highway speeds, although that's not really what they're intended for.

For a camper top where the Jeep is open to the bed area, I would think these would be very handy, or if you're running slowly on a bug-infested trail they could be used to allow air but not bugs into the Jeep.

This isn't a product listing, it's more of a short "how to" article.

It appears he's just using magnetic strips to hold loose window screen in place. I did a similar thing a few years back but I sandwiched the edge of the screen between the magnetic strip and webbing and sewed everything together. Also he put the screen on the inside, I put mine on the outside.

From the inside:

They can be rolled up for storage:

The magnetic strips do a good job at holding them in place - I ran around town with the window open and the screen in place, topping out at around 50mph and had no problem with the screen staying in place, although screens do make some wind noise at speed. They'd probably stay in place at highway speeds, although that's not really what they're intended for.

For a camper top where the Jeep is open to the bed area, I would think these would be very handy, or if you're running slowly on a bug-infested trail they could be used to allow air but not bugs into the Jeep.

jscherb

Expedition Leader

More Aluminum Boxes

I've posted a number of things about the widespread use of aluminum boxes on Land Rovers for carrying gear and supplies, here's another one. This photo is from 1957 (63 years ago) and several aluminum boxes are visible. Aluminum boxes have been popular with Land Rovers for a very long time.

I've posted a number of things about the widespread use of aluminum boxes on Land Rovers for carrying gear and supplies, here's another one. This photo is from 1957 (63 years ago) and several aluminum boxes are visible. Aluminum boxes have been popular with Land Rovers for a very long time.

jscherb

Expedition Leader

I'm working on the gutter mounts for the rack extension. I bought an inexpensive gutter-mount van ladder rack (https://www.amazon.com/MaxxHaul-70440-montaje-canaleta-capacidad/dp/B019DP6UG0) with the idea that I could modify the gutter mounts and use just them and as a fallback I could use the gutter mounts plus the included crossbar:

It worked out that modifying the gutter mounts is all that was needed. The rack is about 2" narrower than the gutters, so I modified the gutter mounts to jog in 1" on each side.

In these next photos the mount in the foreground is modified and the straight one in the back is unmodified. The modified one is still taller than necessary so it'll be trimmed shorter in the next step when I connect it to the rack extension. When the main rack basket is off the Jeep, it hangs from the garage door rails several inches above the Jeep - it's hanging in these photos so it'll be several inches lower when it's on the Jeep.

The unmodified mount is leaning inwards a bit in these photos, with the rack lowered onto the Jeep it would lean even more. I'm sizing the mounts to the main rack basket in these photos because it's sitting above the Jeep right now but the extension is the same width so the size will be the same.

Tip for bending something like this: these are made from 1/4" steel, which would be tough to bend nicely, so I used a cutoff wheel in my angle grinder to make a groove at each bend location. The groove is slightly deeper than halfway through the metal, leaving a fairly thin bit of metal to bend. Once bent, the groove is welded up to restore the strength. The grooves are made on the outside of the bend so when bent the groove will open up, making it easy to lay a nice fillet of weld in the groove and get great penetration.

While I had the welder set up, I replaced the 6mm nuts welded to the brackets for the clamp bolts with 1/4" nuts. The Surco rack adapters I use to mount the main rack to the Jeeps secure with 1/4" bolts so by making this change only one size wrench is required to secure everything.

The JKU roof is a bit wider and slightly lower than the LJ roof but I believe I can make these same mounts work on that Jeep too, but if that doesn't work I still have the second set that I can modify.

It worked out that modifying the gutter mounts is all that was needed. The rack is about 2" narrower than the gutters, so I modified the gutter mounts to jog in 1" on each side.

In these next photos the mount in the foreground is modified and the straight one in the back is unmodified. The modified one is still taller than necessary so it'll be trimmed shorter in the next step when I connect it to the rack extension. When the main rack basket is off the Jeep, it hangs from the garage door rails several inches above the Jeep - it's hanging in these photos so it'll be several inches lower when it's on the Jeep.

The unmodified mount is leaning inwards a bit in these photos, with the rack lowered onto the Jeep it would lean even more. I'm sizing the mounts to the main rack basket in these photos because it's sitting above the Jeep right now but the extension is the same width so the size will be the same.

Tip for bending something like this: these are made from 1/4" steel, which would be tough to bend nicely, so I used a cutoff wheel in my angle grinder to make a groove at each bend location. The groove is slightly deeper than halfway through the metal, leaving a fairly thin bit of metal to bend. Once bent, the groove is welded up to restore the strength. The grooves are made on the outside of the bend so when bent the groove will open up, making it easy to lay a nice fillet of weld in the groove and get great penetration.

While I had the welder set up, I replaced the 6mm nuts welded to the brackets for the clamp bolts with 1/4" nuts. The Surco rack adapters I use to mount the main rack to the Jeeps secure with 1/4" bolts so by making this change only one size wrench is required to secure everything.

The JKU roof is a bit wider and slightly lower than the LJ roof but I believe I can make these same mounts work on that Jeep too, but if that doesn't work I still have the second set that I can modify.

jscherb

Expedition Leader

Some interesting details on this Alu-Cab camper equipped Defender. Like this box on the bonnet:

It's a storage compartment they're using for firewood:

I can't imagine seeing something like that on a Jeep. Also note the shovel mounted on the fender.

On the driver side (it's RHD), a cargo hatch tool compartment, with a swing-down table. Looks like this one mounts outside of the hardtop instead of being a window replacement:

On the passenger side, a kitchen cabinet with a swing-down table. It appears this mounts outside the hardtop like the one on the other side, it's a little hard to tell from this photo:

I wonder if boxes that mount outside the hardtop like these would interest Jeep people?

That's a separate table; what I was planning for the JK/JL cargo hatch project would be three options. The first would be a glass panel that hinged up, the second would be an aluminum panel instead of the glass and it would hinge down to serve as a table. In this next photo a glass prototype is posed upside down to see what the table option might look like:

And the third option would be an aluminum panel hinged to swing up; it could be used to mount things on, like a Rotopax.

All three options are simple variations of the same parts with the version being decided at final assembly time so it would be very cost-effective to produce all of them.

It's a storage compartment they're using for firewood:

I can't imagine seeing something like that on a Jeep. Also note the shovel mounted on the fender.

On the driver side (it's RHD), a cargo hatch tool compartment, with a swing-down table. Looks like this one mounts outside of the hardtop instead of being a window replacement:

On the passenger side, a kitchen cabinet with a swing-down table. It appears this mounts outside the hardtop like the one on the other side, it's a little hard to tell from this photo:

I wonder if boxes that mount outside the hardtop like these would interest Jeep people?

That's a separate table; what I was planning for the JK/JL cargo hatch project would be three options. The first would be a glass panel that hinged up, the second would be an aluminum panel instead of the glass and it would hinge down to serve as a table. In this next photo a glass prototype is posed upside down to see what the table option might look like:

And the third option would be an aluminum panel hinged to swing up; it could be used to mount things on, like a Rotopax.

All three options are simple variations of the same parts with the version being decided at final assembly time so it would be very cost-effective to produce all of them.

Last edited:

jscherb

Expedition Leader

Any chance of you making them for the TJ Unlimiteds as well?

BTW there was an attempt by someone to bring a TJ cargo window to market a few years ago, they were calling it the TJ Side Access Slider. I'm not sure if they ever got it to market or sold any, but styling wasn't their main selling point

BTW there was an attempt by someone to bring a TJ cargo window to market a few years ago, they were calling it the TJ Side Access Slider. I'm not sure if they ever got it to market or sold any, but styling wasn't their main selling point.

Man, thats a nasty looking piece of equipment.

jscherb

Expedition Leader

I tested the new ground anchor today.

The ground is pretty solid clay at my house so I did the test with only 4 stakes. If they looked unstable when I started the pull, I would have put in more stakes.

The test was to pull the LJ over a berm at the top of the driveway.

Since it was a short distance pull and I wasn't spooling too much line out, I did a double line pull - the more wraps on the drum, the lower the power/higher the amp draw and doubling the line doubles the power/cuts the amp draw.

The test:

The stakes are designed so that removal is made easier by using another stake (or the Jeep's lug wrench) to twist the stake and pull it out.

Test passed. The ground anchor works as intended so I'll declare it ready for use on the trail.

The ground is pretty solid clay at my house so I did the test with only 4 stakes. If they looked unstable when I started the pull, I would have put in more stakes.

The test was to pull the LJ over a berm at the top of the driveway.

Since it was a short distance pull and I wasn't spooling too much line out, I did a double line pull - the more wraps on the drum, the lower the power/higher the amp draw and doubling the line doubles the power/cuts the amp draw.

The test:

The stakes are designed so that removal is made easier by using another stake (or the Jeep's lug wrench) to twist the stake and pull it out.

Test passed. The ground anchor works as intended so I'll declare it ready for use on the trail.

jscherb

Expedition Leader

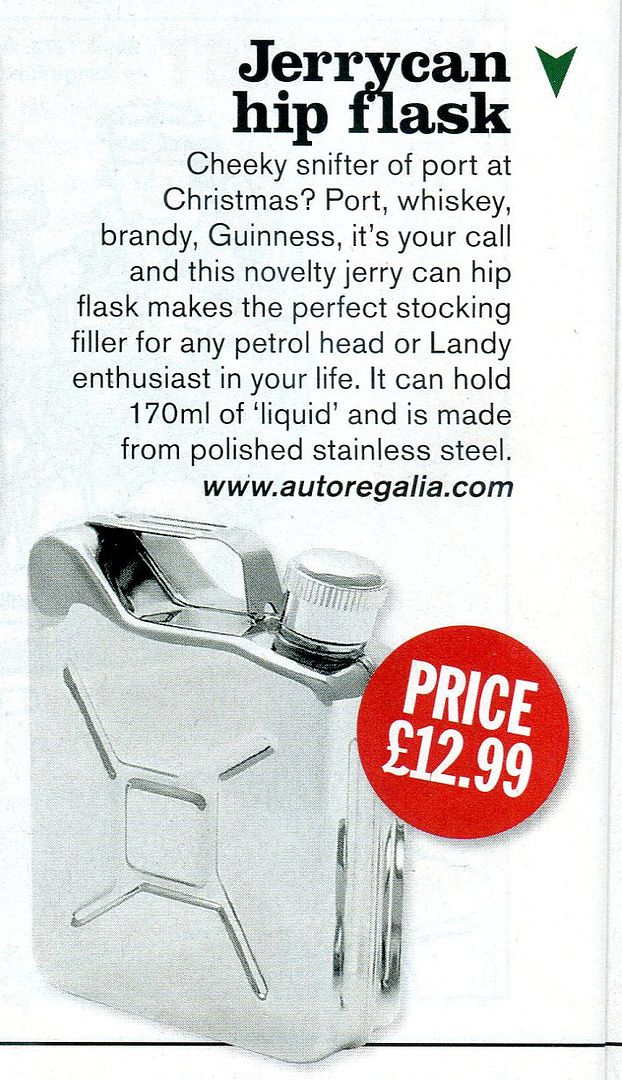

One thing both Land Rover and Jeep people have in common is a fondness for jerry cans. This was in a holiday gift guide in the magazine:

I found them at a military surplus place in Pennsylvania a few years ago and I couldn't resist buying a couple. I tried some fun photography with one:

They fit nicely in a pouch on my roll bar:

I checked the surplus place web site and they still sell them: https://colemans.com/stainless-steel-jerry-can-flask

I found them at a military surplus place in Pennsylvania a few years ago and I couldn't resist buying a couple. I tried some fun photography with one:

They fit nicely in a pouch on my roll bar:

I checked the surplus place web site and they still sell them: https://colemans.com/stainless-steel-jerry-can-flask

Florida Native

Active member

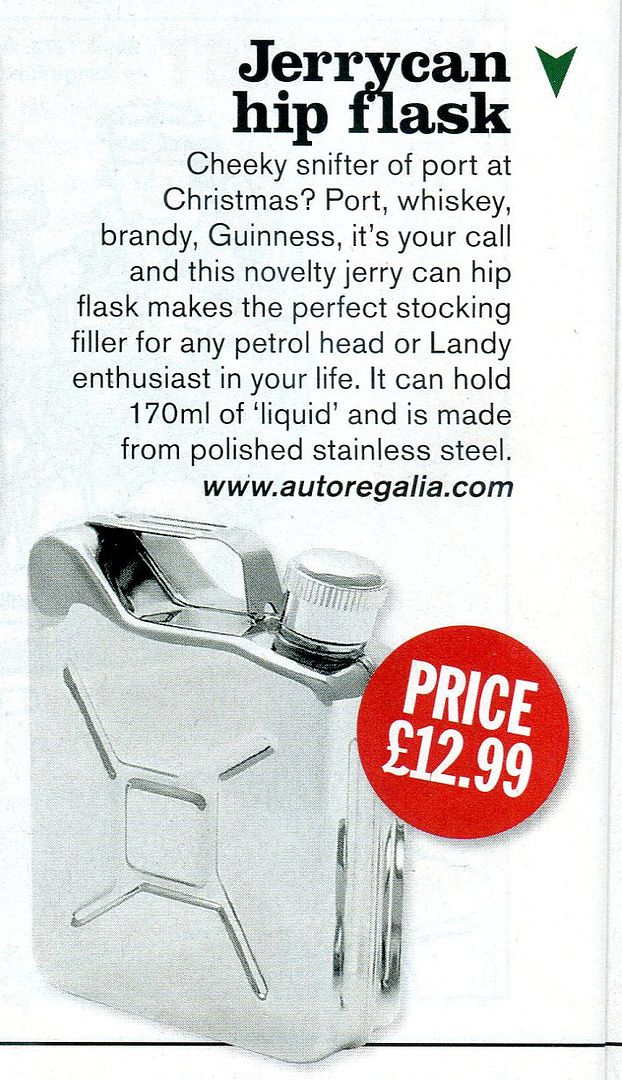

I am 98% sure the Eno Roadie has been discontinued. However, there are still a few places where you can still get them...

www.sierra.com

www.sierra.com

-Mike

Sent from my SM-G950U using Tapatalk

ENO Roadie Hammock Car Stand 843MA - Save 49%

ENO Roadie Hammock Car Stand 843MA at Sierra. Celebrating 30 Years Of Exploring.

-Mike

Sent from my SM-G950U using Tapatalk

jscherb

Expedition Leader

Discovery License Housing Switch Panel

Lots of people want to add gauges and switches to their Jeeps but there isn't much room on the stock dash. Here's an interesting idea for a gauge/switch pod to mount on top of the dash.

.jpg?width=1920&height=1080&fit=bounds)

They don't say which year Disco the part comes from, here's a Disco 1, which is not uncommon in junkyards around here (I checked but there aren't any at the local u-pull at the moment)...

You can still see the green oval on the top of the pod in the first photo, I guess for Jeep use you'd want to remove that .

.

Lots of people want to add gauges and switches to their Jeeps but there isn't much room on the stock dash. Here's an interesting idea for a gauge/switch pod to mount on top of the dash.

.jpg?width=1920&height=1080&fit=bounds)

They don't say which year Disco the part comes from, here's a Disco 1, which is not uncommon in junkyards around here (I checked but there aren't any at the local u-pull at the moment)...

You can still see the green oval on the top of the pod in the first photo, I guess for Jeep use you'd want to remove that

jscherb

Expedition Leader

Based on the photos in the magazines of Land Rover camper conversions you might think that the Defender is larger than a Jeep...

But it really isn't bigger. A few dimensions...

The rear tailgate opening is 34" wide compared to the TJ's 36". The JK and JL tailgates are a few inches wider. The space between the inner fenders is less than that on the TJ as well. The interior width is 55/56", which is roughly the same as the TJ. The interior height is only a little taller than the TJ with factory hardtop.

But it really isn't bigger. A few dimensions...

The rear tailgate opening is 34" wide compared to the TJ's 36". The JK and JL tailgates are a few inches wider. The space between the inner fenders is less than that on the TJ as well. The interior width is 55/56", which is roughly the same as the TJ. The interior height is only a little taller than the TJ with factory hardtop.

Similar threads

- Replies

- 0

- Views

- 1K

- Replies

- 16

- Views

- 480

- Replies

- 2

- Views

- 2K

- Replies

- 2

- Views

- 2K