Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Land Rover ideas for Jeeps

- Thread starter jscherb

- Start date

jscherb

Expedition Leader

I agree a detached piece of Velcro would work as well for securing the excess end of a strap, but I sewed the slot in it so it can't get lost - it'll always be on the strap when I need it. The slot doesn't prevent the Velcro from being positioned where needed on the strap because it slides along the strap but it does prevent the Velcro from getting lost.The Velcro wrap method is a popular means of accomplishing the same thing on backpack straps. I use them often, and they work well. There’s really no need to sew anything though - they hold fine as a simple wrap.

And sewing isn't strictly necessary, cutting two simple slits in the Velcro to thread the strap through will do just fine, although the sewed version is probably slightly more durable because the Velcro doesn't have cuts in it.

Here's the no-sew version, cut two slits a little more than 1" wide in a piece of Velcro One-Wrap to pass 1" webbing through:

bitbckt

Member

I can’t think of a time when I’ve lost a velcro strap on however many thousands of trail miles I’ve had them on my packs and Jeep - they are always “in use”, wrapped around the webbing they are intended to secure.

Which is not to say that sewing/cutting them has no merit whatsoever, but it seems like an over-complication of an essentially very simple premise.

Shrug.

Which is not to say that sewing/cutting them has no merit whatsoever, but it seems like an over-complication of an essentially very simple premise.

Shrug.

Thanks for taking the time to make and demo those. I agree on the steel G clips as well and great idea with the strap keepersI picked up a roller cam buckle to see how well they work. I sewed a strap with it and with G-hooks on either end as a test.

On the rack:

These buckles hold very well, they seem to hold better than the non-roller variety. With the roller buckle and the G-hook ends these are very useful straps.

A couple of caveats though - I only sewed one strap so far, and securing something like the slippery and heavy (when full) military Scepter container shown above really would need two straps crossed over it to secure it well, so don't take my photo above with one strap as a recommended practice. The G-hooks I used are aluminum and I think under very heavy loads they might bend, so I think the best practice for G-hooks would be to double-wrap the end, that way there's almost no stress on the hook:

The G-hooks I used are aluminum, for heavier loads steel hooks would be stronger. Here's a source for heat-treated steel G-hooks which would probably be much stronger than the aluminum ones I used: https://www.rockywoods.com/G-Hook-wave-1-Slot-Size-Heat-Treated-Steel-Berry-Compliant

For many heavier things I think I'll still prefer ratchet straps, but roller cam buckle straps seem to be a good option for all but the heaviest stuff.

One thing that always bothers me about straps - what to do with the loose end? I came up with something to keep the excess end of the strap under control. It's a pretty simple piece of Velcro One-Wrap sewed so it can slide over any strap; once the excess strap is folded the One-Wrap is used to secure the excess - I'll call it a "Strap Keeper"...

In this photo the excess strap is contained by the Strap Keeper:

The Strap Keeper on the sewing table:

I plan to make Strap Keepers for all of my ratchet straps - I can never figure out what to do with the loose ends after I secure something with them and the Strap Keeper solves that problem very nicely.

BTW here's a source for roller cam buckles if anyone wants to sew their own (they also sell premade straps): https://www.rollercam.com/shop/rollercam-buckle. Another source for premade roller cam buckle straps is Multus: https://www.multusproducts.com/search.php?search_query=roller

Paddler Ed

Adventurer

I used to tie off my cam lock straps with some half hitches; this reduced the risk of them slipping as well as tidying up the excess strap. This has worked well for 1,000s of miles of carrying kayaks and canoes using cam buckles. We used cam buckles as ratchet straps are too easy to overtighten and then damage the hull of the boats.

jscherb

Expedition Leader

Thank you. Under the Murphy's Law corollary "Whatever Can Get Lost, Will", I'm going to make up Strap Keepers like the one I posted for all of my straps and slide them onto the straps so they're always ready for useThanks for taking the time to make and demo those. I agree on the steel G clips as well and great idea with the strap keepers

zgfiredude

Active member

From my motorcycling days, I've been the habit of a half hitch tied under the buckle, and the excess strap done in "electrician's loop" style of successive slip knots on alternating sides of the main strap. One pull of the end and it all releases to the half hitch. Secure even when wet, and not flapping in the wind.

Also, I've taken to using these: ROK Straps for a lot of my needs.

Also, I've taken to using these: ROK Straps for a lot of my needs.

jscherb

Expedition Leader

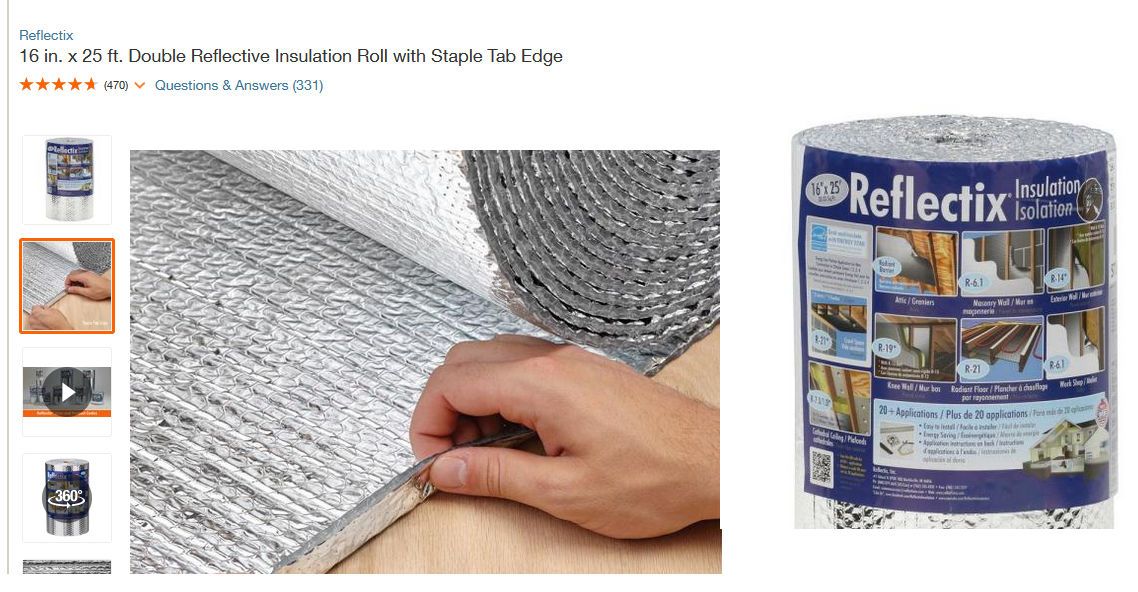

In the August issue of Land Rover Owner, regular contributor Vicky Turner has a DIY article on making insulated blinds for sleeping in her Land Rover.

Typical British humor:

Seems like these could be useful for people who sleep in their Jeeps, and maybe Ursa Minor owners, and since it took me a few reads of the article to fully understand what she did I'll summarize/paraphrase the article here.

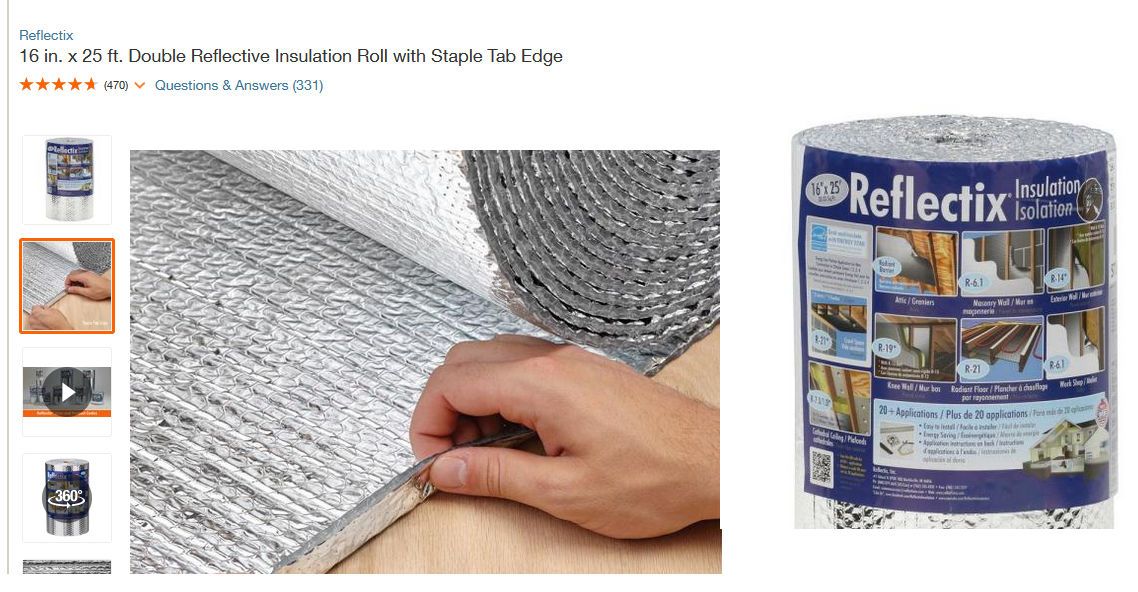

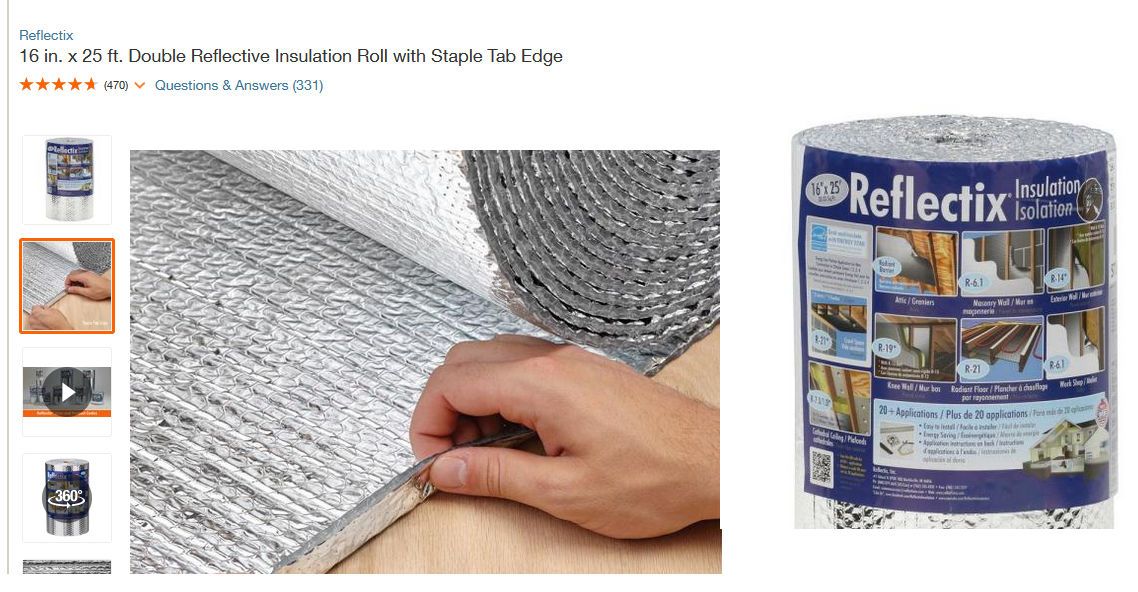

She made the blinds out of mylar-foil covered insulation. She used something like this, which can be found at Home Depot and Lowes:

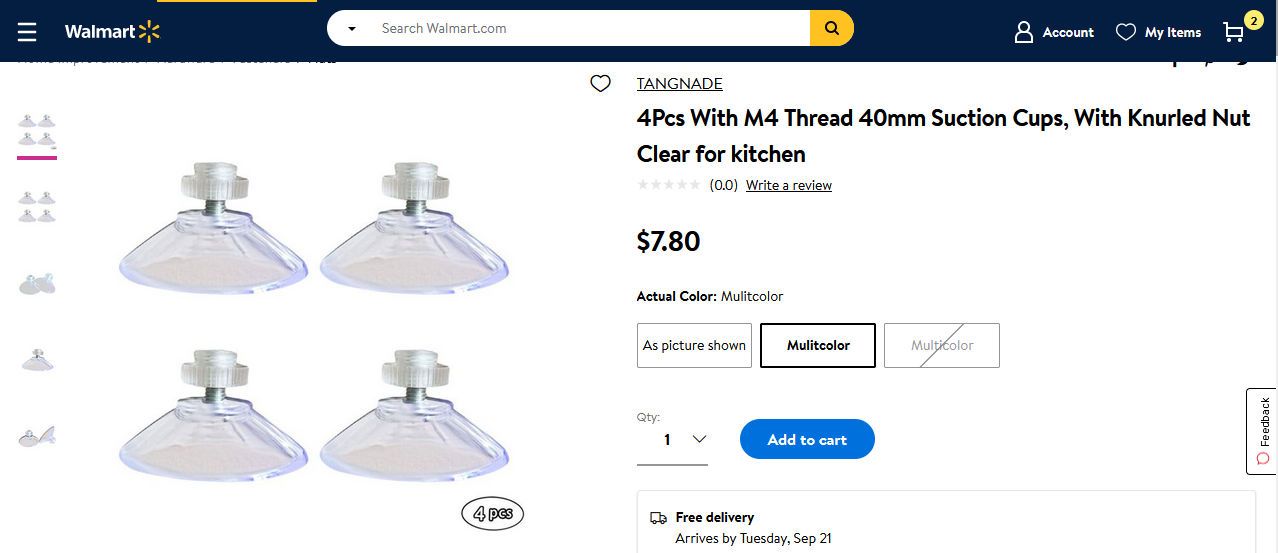

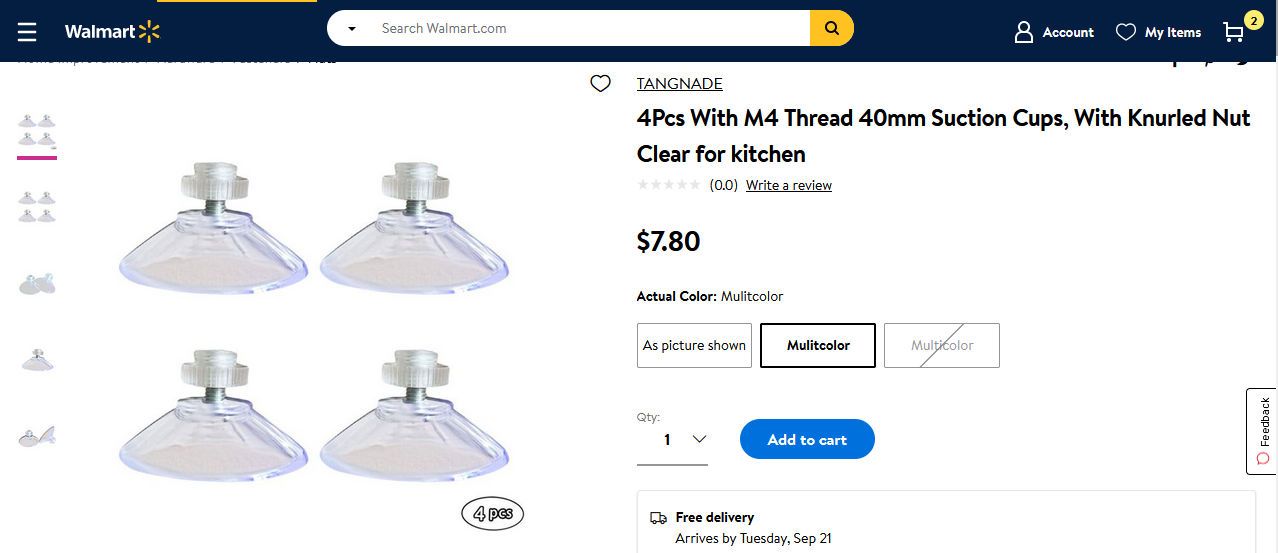

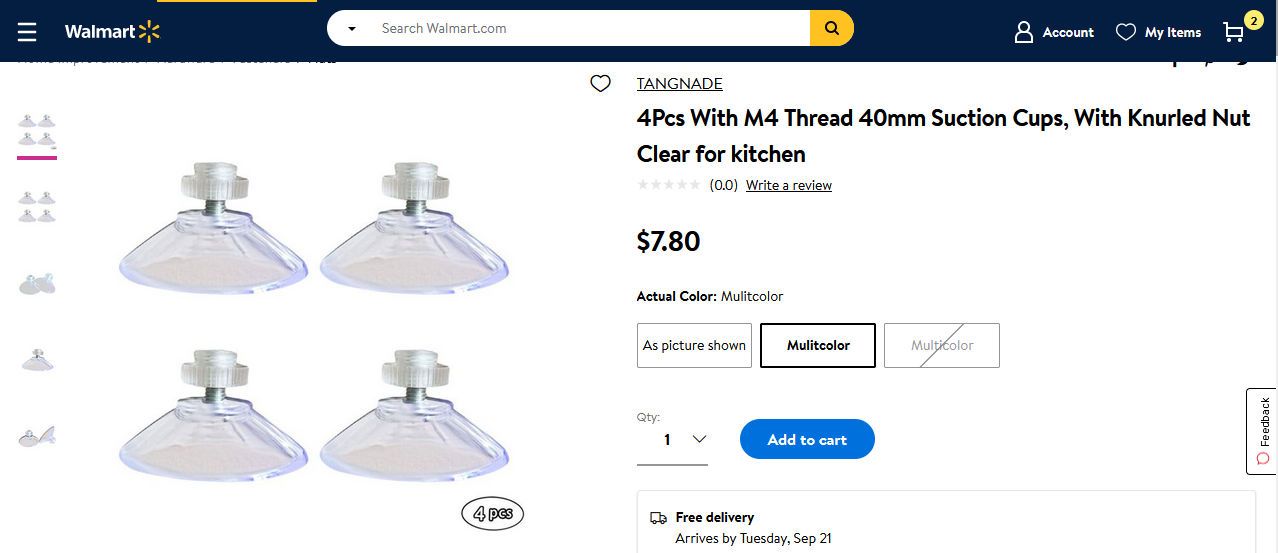

She attaches her blinds with suction cups. She used cups with threaded studs on the back like these found on walmart.com:

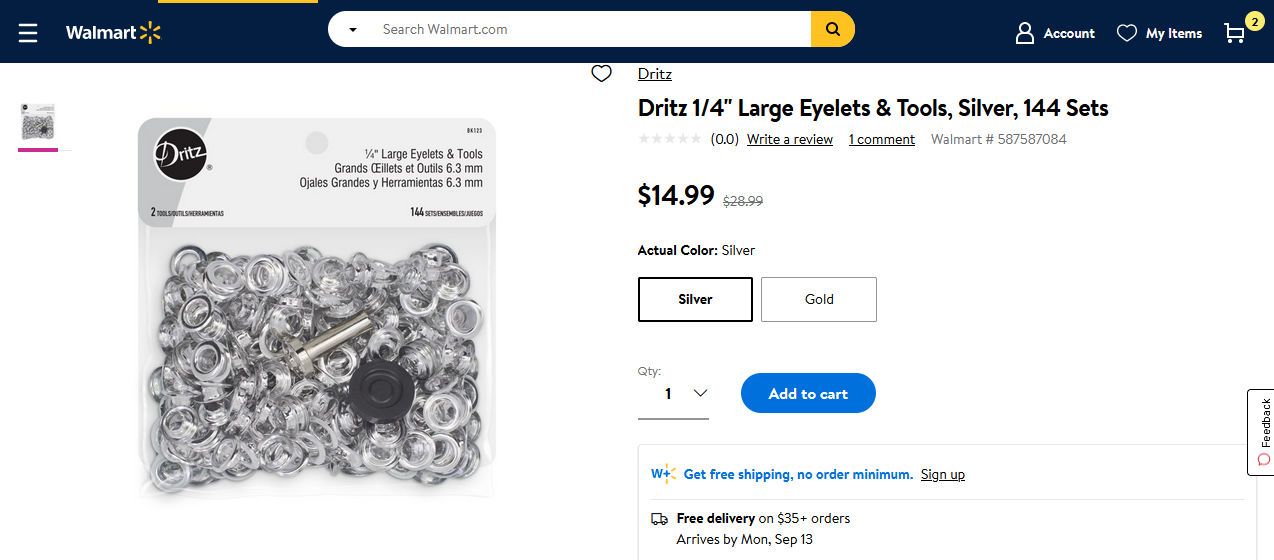

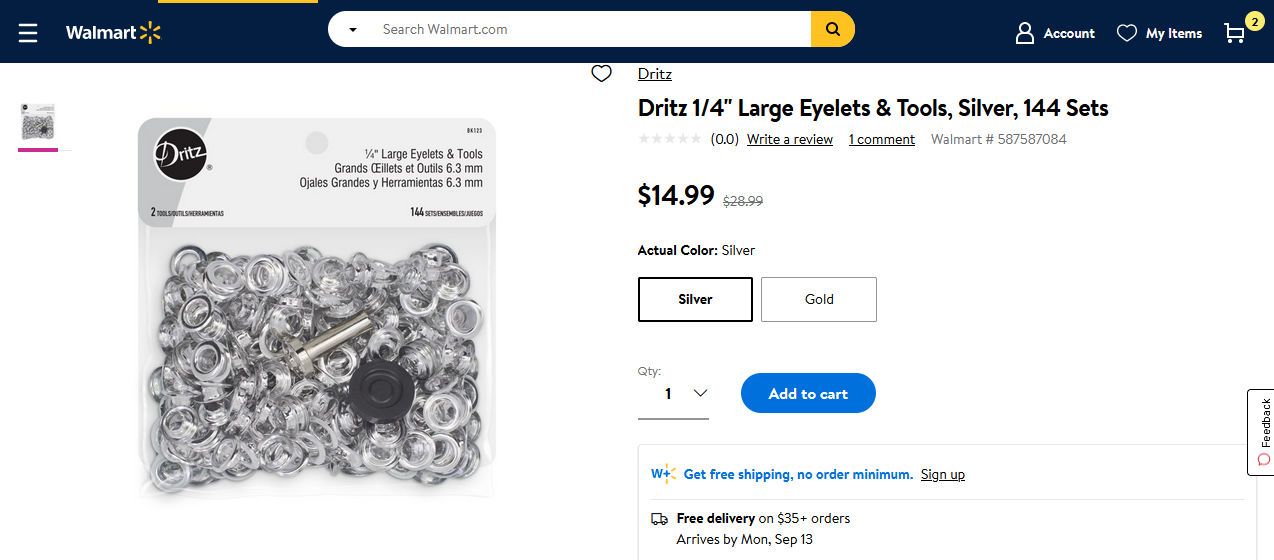

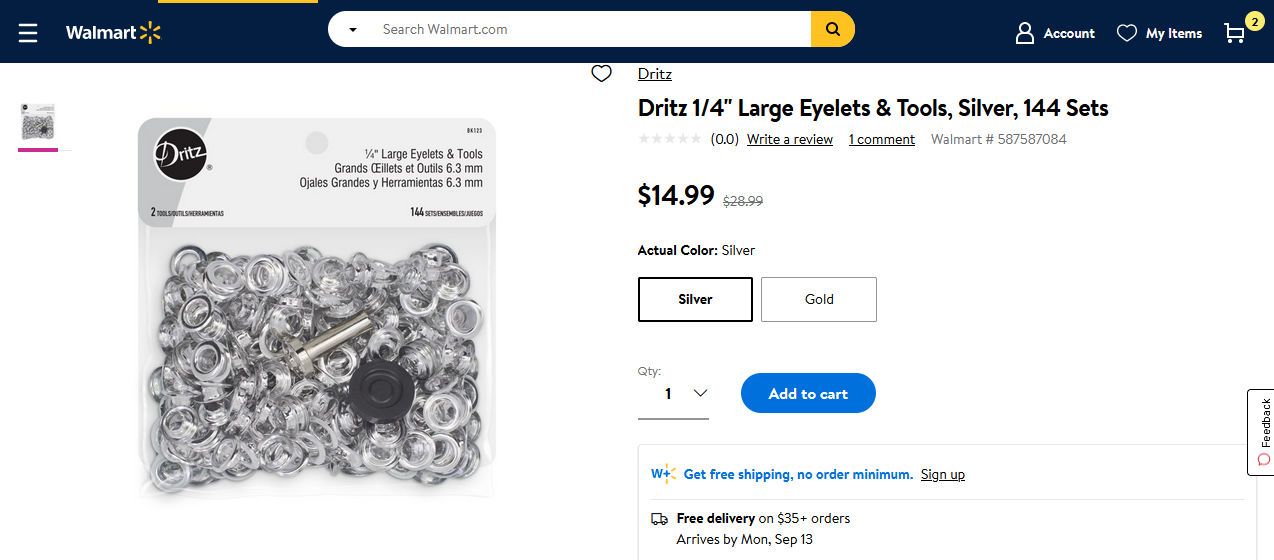

The suction cup studs go through holes in the blinds. The holes are reinforced with eyelets like these, also from walmart.com:

She trims the edges with duct tape. In this closer photo you can maybe make out how the duct tape edging works and you can see one of the suction cup studs through an eyelet in the lower right corner:

Seems like a pretty simple project. Maybe something like this will be useful to someone here.

Typical British humor:

Seems like these could be useful for people who sleep in their Jeeps, and maybe Ursa Minor owners, and since it took me a few reads of the article to fully understand what she did I'll summarize/paraphrase the article here.

She made the blinds out of mylar-foil covered insulation. She used something like this, which can be found at Home Depot and Lowes:

She attaches her blinds with suction cups. She used cups with threaded studs on the back like these found on walmart.com:

The suction cup studs go through holes in the blinds. The holes are reinforced with eyelets like these, also from walmart.com:

She trims the edges with duct tape. In this closer photo you can maybe make out how the duct tape edging works and you can see one of the suction cup studs through an eyelet in the lower right corner:

Seems like a pretty simple project. Maybe something like this will be useful to someone here.

Chorky

Observer

I do this all the time in the passenger windows of my truck. Actually the original idea was not for sleeping at all but rather to keep them up during the day to reduce sun radiation from getting in the cab and heating it so darn hot. It has worked well and now they have been in the truck full time for about 3 years. If I wanted something specifically for privacy I thnk a different material would be better. Even a black painted cardboard would be better. It's flatter, holds shape better, and looks more incognito. These things in the windows do sorta make a person look somewhat like a homeless meth head.

pith helmet

Well-known member

I use that, too. If you work with it just a bit it will fit inside the rubber weatherstripping without anything to hold it like suction cups. In the front and back I use ready made windshield sunscreens, the back one being a large for a full size truck. It’s a total blackout in there.In the August issue of Land Rover Owner, regular contributor Vicky Turner has a DIY article on making insulated blinds for sleeping in her Land Rover.

Typical British humor:

Seems like these could be useful for people who sleep in their Jeeps, and maybe Ursa Minor owners, and since it took me a few reads of the article to fully understand what she did I'll summarize/paraphrase the article here.

She made the blinds out of mylar-foil covered insulation. She used something like this, which can be found at Home Depot and Lowes:

She attaches her blinds with suction cups. She used cups with threaded studs on the back like these found on walmart.com:

The suction cup studs go through holes in the blinds. The holes are reinforced with eyelets like these, also from walmart.com:

She trims the edges with duct tape. In this closer photo you can maybe make out how the duct tape edging works and you can see one of the suction cup studs through an eyelet in the lower right corner:

Seems like a pretty simple project. Maybe something like this will be useful to someone here.

jscherb

Expedition Leader

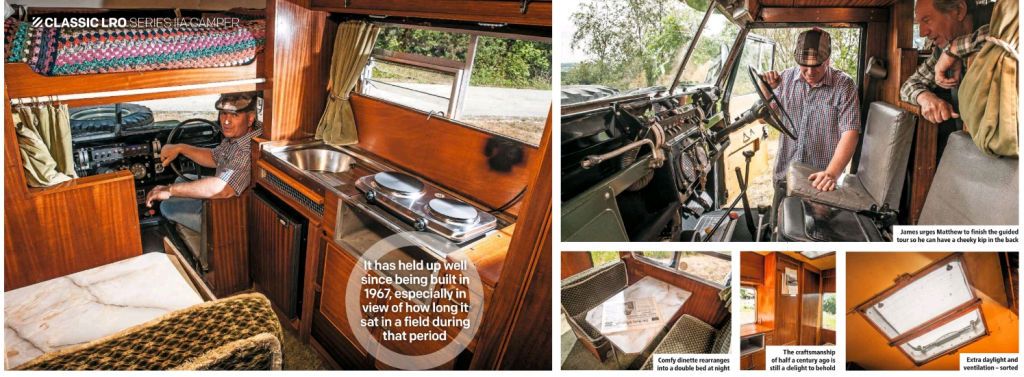

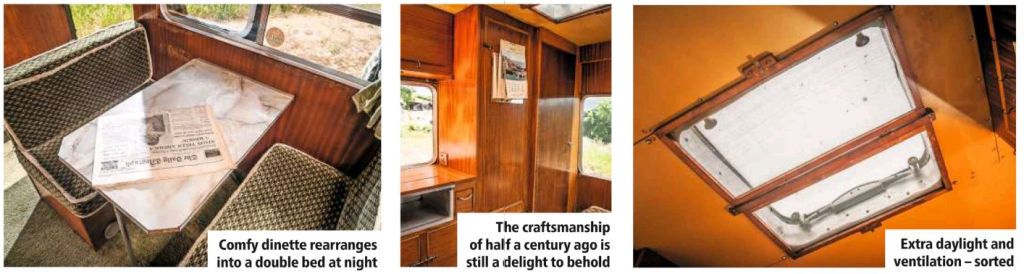

There's a story in the October issue of Land Rover Owner about a 1960's/70's Jennings Camper. They were made for a variety of vehicles but as far as is known, only 3 were made for Land Rover chassis.

What if one were made for a Wrangler? I wanted to see what it might look like so here's a quick photoedit:

What if one were made for a Wrangler? I wanted to see what it might look like so here's a quick photoedit:

Jim K in PA

Adventurer

What does the interior layout look like?

Looks like you shortened the rear overhang a bit. The overhang on the LR is substantial, and makes off-road travel with this barn a challenge.

Looks like you shortened the rear overhang a bit. The overhang on the LR is substantial, and makes off-road travel with this barn a challenge.

jscherb

Expedition Leader

I tried to keep the wheelbase at JKU length because that's what something like this might be built on. And the overhang ended up being better that way.What does the interior layout look like?

Looks like you shortened the rear overhang a bit. The overhang on the LR is substantial, and makes off-road travel with this barn a challenge.

jscherb

Expedition Leader

What does the interior layout look like?

These are all the photos the article had of the interior.

One more exterior shot:

jscherb

Expedition Leader

When I think of magnetic tail lights, I think of these:

I have a set and I use them for whenever I tow one of my Jeeps with another one of my Jeeps - these give the towed vehicle all the lights needed. But because the bases are designed to sit flat on top of a steel surface, they're hard to use when I tow the plastic-bumpered JKU.

I found these in the October issue of Land Rover Owner:

They can be found in the U.S., this search should turn some up: https://www.google.com/search?q=sparex+magnetic+connix

This image is from an eBay listing I found for them.

These seem like they would be usable in more situations than the ones I've got.

And if you're wondering why I might need to tow one of my Jeeps with another of my Jeeps, here's the most recent example - last winter the starter in the JKU failed. The good news is that it failed in the garage so I wasn't stranded anywhere, but I didn't feel like fixing it myself so I had to get the JKU to the dealer. I installed the winch mount, hooked up the tow bar I adapted to work with the mount and towed the JKU to the dealer with the pickup.

I didn't use the magnetic lights for this tow because there really wasn't a place to stick them on the JKU and it was early in the morning so there wasn't anyone else on the road so I just used the JKU's hazard flashers. But if I had these magnetic lights I would have used them.

I have a set and I use them for whenever I tow one of my Jeeps with another one of my Jeeps - these give the towed vehicle all the lights needed. But because the bases are designed to sit flat on top of a steel surface, they're hard to use when I tow the plastic-bumpered JKU.

I found these in the October issue of Land Rover Owner:

They can be found in the U.S., this search should turn some up: https://www.google.com/search?q=sparex+magnetic+connix

This image is from an eBay listing I found for them.

These seem like they would be usable in more situations than the ones I've got.

And if you're wondering why I might need to tow one of my Jeeps with another of my Jeeps, here's the most recent example - last winter the starter in the JKU failed. The good news is that it failed in the garage so I wasn't stranded anywhere, but I didn't feel like fixing it myself so I had to get the JKU to the dealer. I installed the winch mount, hooked up the tow bar I adapted to work with the mount and towed the JKU to the dealer with the pickup.

I didn't use the magnetic lights for this tow because there really wasn't a place to stick them on the JKU and it was early in the morning so there wasn't anyone else on the road so I just used the JKU's hazard flashers. But if I had these magnetic lights I would have used them.

Last edited:

Similar threads

- Replies

- 0

- Views

- 1K

- Replies

- 16

- Views

- 911

- Replies

- 2

- Views

- 2K

- Replies

- 2

- Views

- 2K