Metcalf

Expedition Leader

Thinking for the day.....

Frame design and permanent crossmembers.

Looking at your typical TJ frame there really are not that many side to side crossmembers. There is the front tube crossmember under the grill, the rear fuel tank/shock crossmember, and the rear bumper. I am fairly sure that the belly plate is designed to function as a major structural crossmember when installed?

As I lay out the frame design this makes me a little nervous, especially on the longer LJ length frame. My plan so far is to have crossmembers....

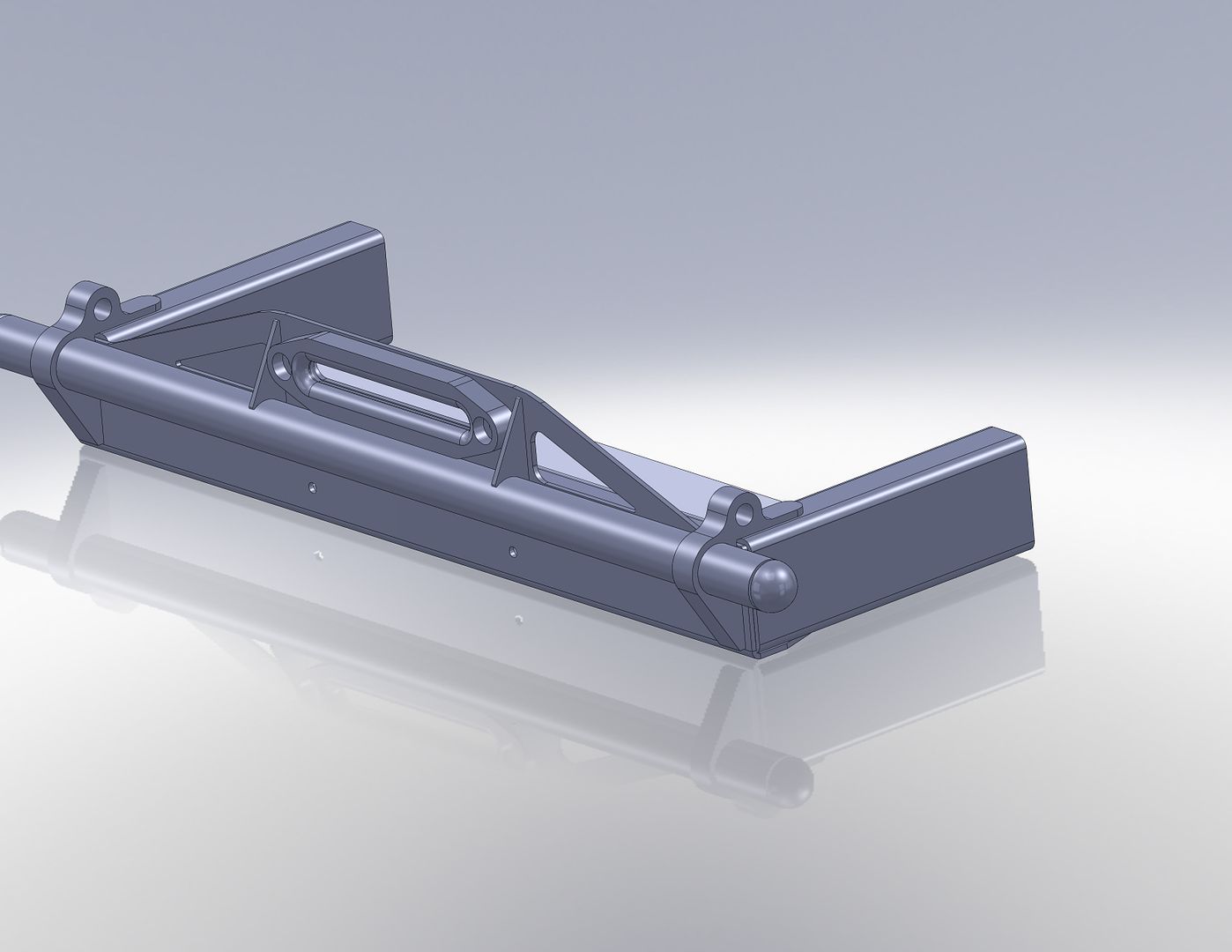

-at the front end of the frame to form the 'bumper', the winch mount, and provide the body mount for the center mount in the grill. This will be a welded in assembly.

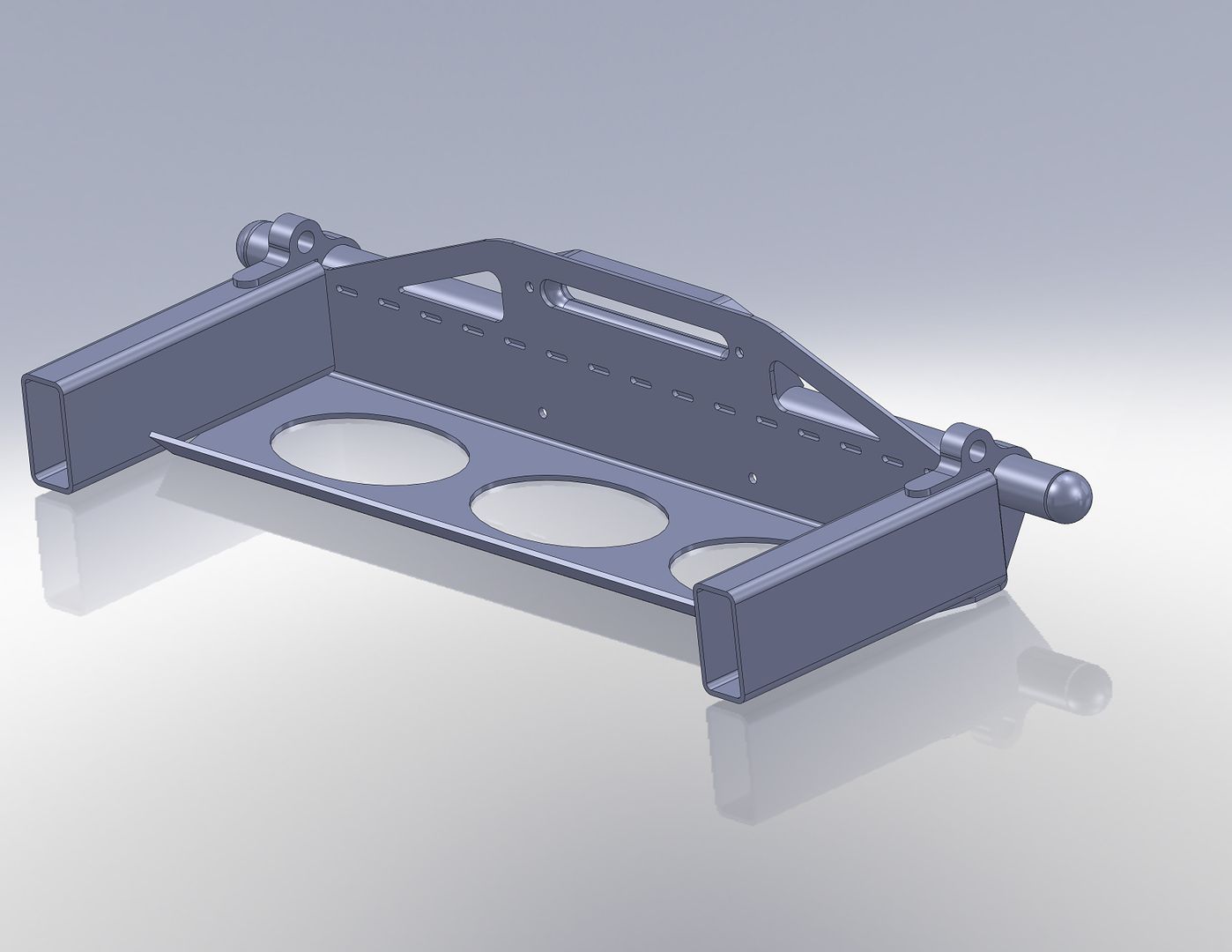

-at the engine mounts. I would like to have a subframe all the way under the engine. It would be nice if this was in more than one part perhaps. It will be a bolt in unit however to allow me more room to move the engine around. The portion under the oil pan will provide a forward attachment point for the belly skidplate. It would be nice if the lower portion of the mount came out perhaps to allow dropping the oil pan off the engine?

-at the transmission mount. This will bolt in also as well as provide the rear end attachment point for the belly skidplate. On the LJ length chassis this is pretty far forward really.

-at the step in the rear floor? I was thinking of adding an arched crossmember that would go above the rear driveshaft at this location. It would be about 18" or so behind the transmission crossmember ( that is removeable ) to provide support to the middle of the chassis. I think with a little planning this could be a welded in unit that may be able to provide support to the B-pillar of the cage where it would tie into the body. I have to run the exhaust, fuel, and brake lines through this area too. It would also be close to the attachment point for the triangulated upper frame side control arm mounts which I think will be important on the longer LJ length frame rails?

-somewhere slightly behind the rear axle. This would be for rear floor support along with providing a mount for the front of the fuel tank. This would also be in the same area as the rear air bag mounts and shock mounts to provide a little more structure in that part of the frame.

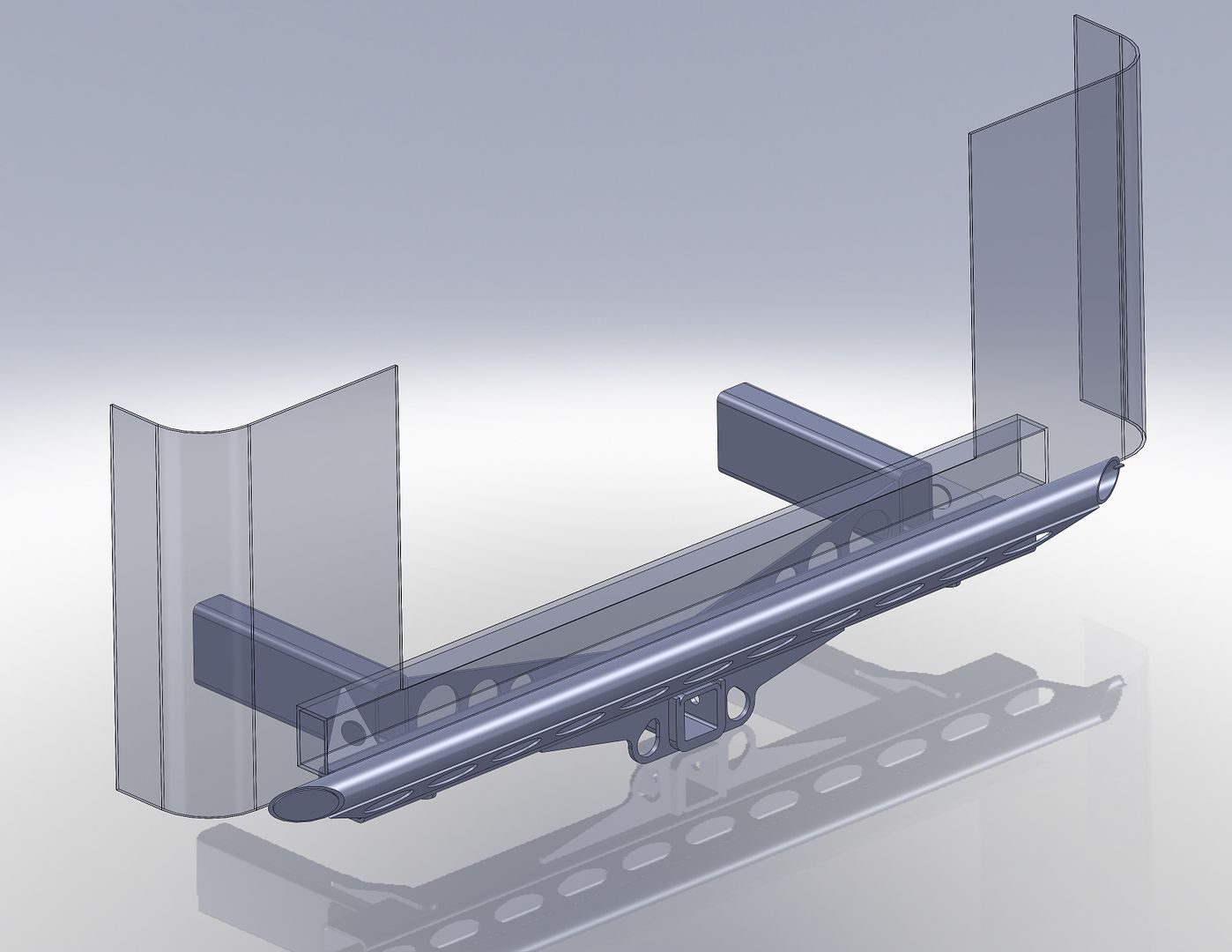

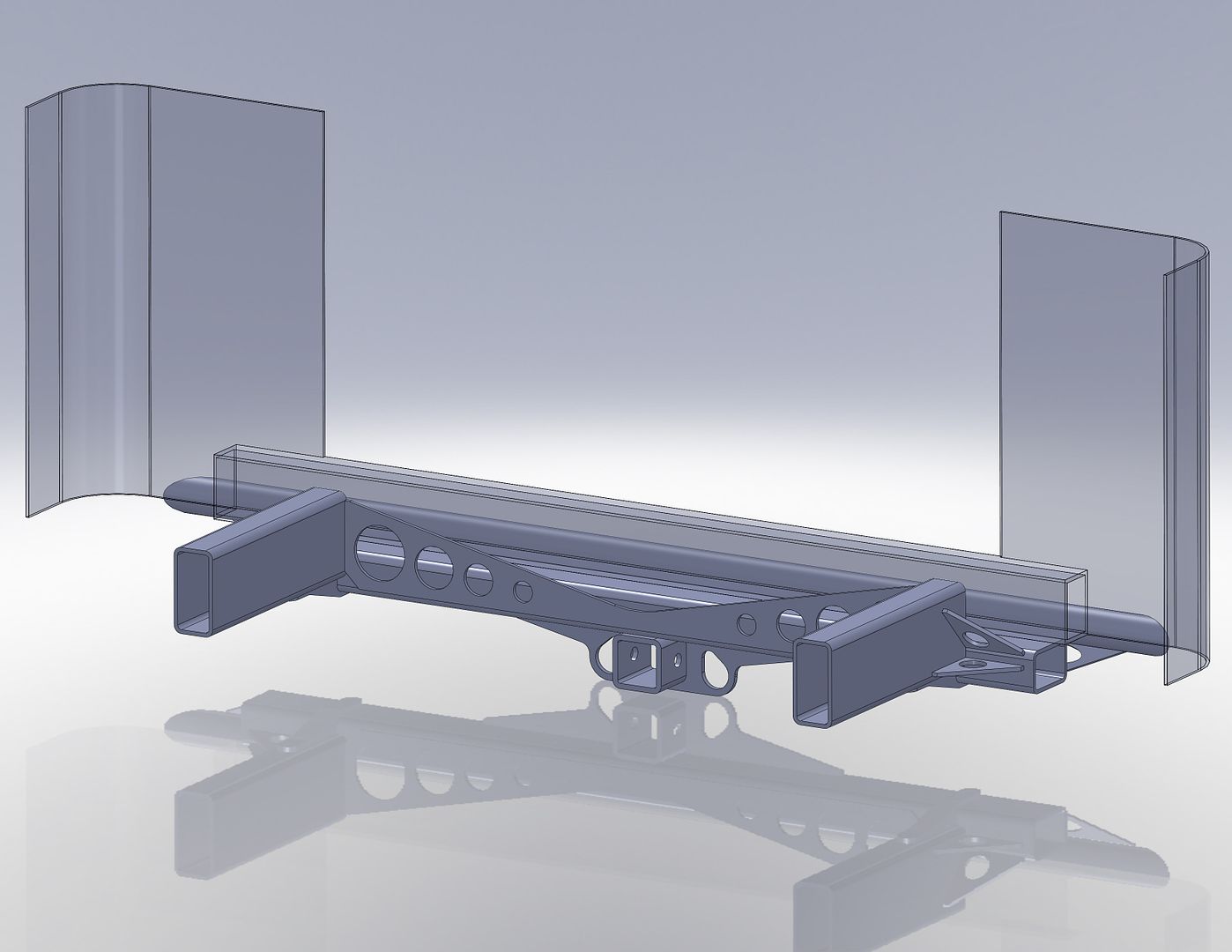

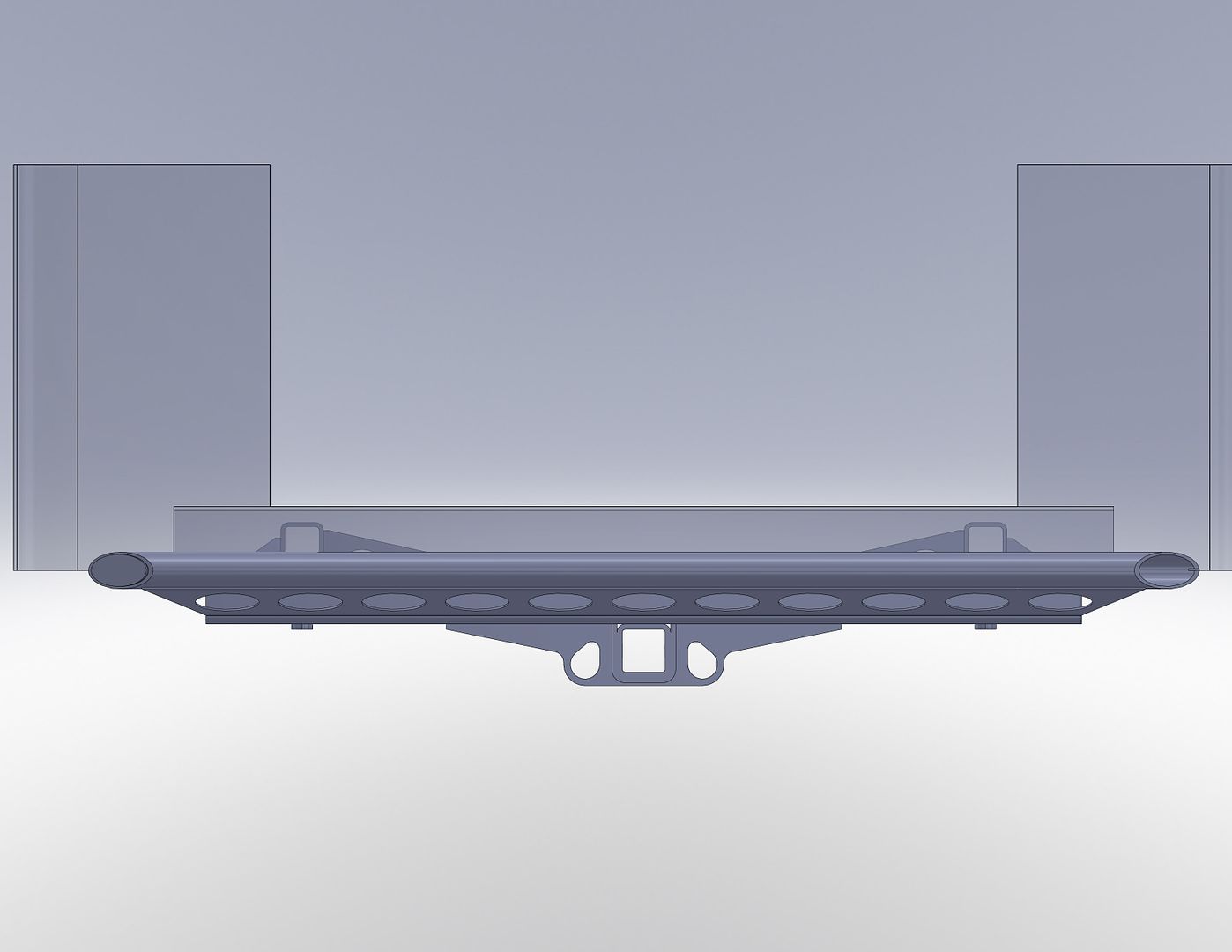

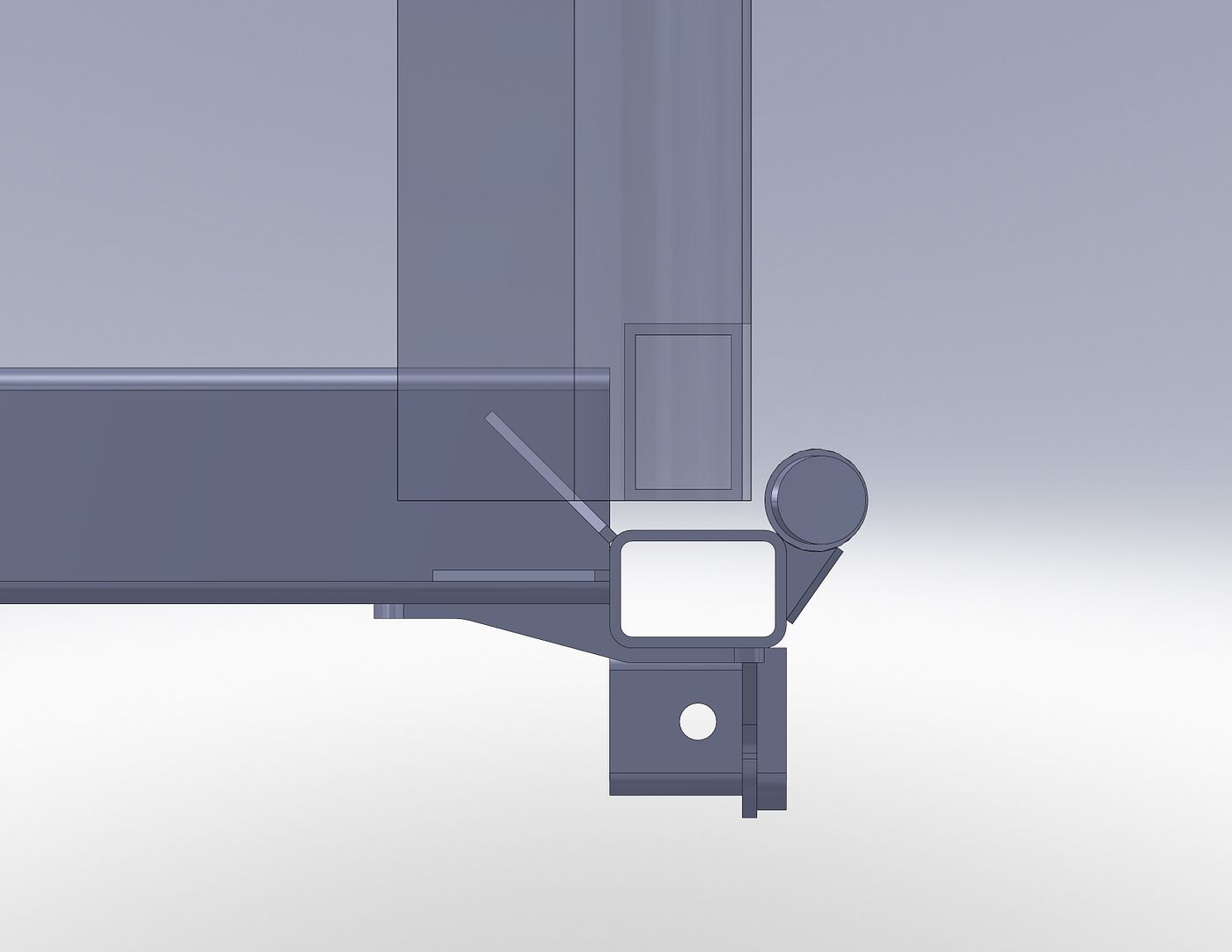

-at the rear bumper. I am trying to design a rear bumper crossmember assembly that integrates the rear body mounts, a tube crossmember for a swaybar, a receiver hitch, and a rear 'bumper' of sorts to protect the body. Oh...and it needs to provide a mount for the rear of the fuel tank....

Think that will give me enough support in the long chassis?

I am still very much on the fence about tying in the cage mounts solidly to the frame. I don't think I want to go all uni-body buggy spaceframe on this vehicle. I think the body and cage tie-in mounts will have to be isolated at this point....

Fun stuff. Once I get some better measurements on the frame I will posts some pictures from Solidworks. I am trying to design the frame in sub-assemblies so that I can just weld in the computer cut crossmembers to the main frame rails once I have the chassis main rails welded up. I finally found a decent solid model of an LS engine so I can computer design the engine mount subframe assembly. The transmission crossmember will probably have to be designed on the fly once I get some parts and see how the clocking on the NP205 ends up.

Frame design and permanent crossmembers.

Looking at your typical TJ frame there really are not that many side to side crossmembers. There is the front tube crossmember under the grill, the rear fuel tank/shock crossmember, and the rear bumper. I am fairly sure that the belly plate is designed to function as a major structural crossmember when installed?

As I lay out the frame design this makes me a little nervous, especially on the longer LJ length frame. My plan so far is to have crossmembers....

-at the front end of the frame to form the 'bumper', the winch mount, and provide the body mount for the center mount in the grill. This will be a welded in assembly.

-at the engine mounts. I would like to have a subframe all the way under the engine. It would be nice if this was in more than one part perhaps. It will be a bolt in unit however to allow me more room to move the engine around. The portion under the oil pan will provide a forward attachment point for the belly skidplate. It would be nice if the lower portion of the mount came out perhaps to allow dropping the oil pan off the engine?

-at the transmission mount. This will bolt in also as well as provide the rear end attachment point for the belly skidplate. On the LJ length chassis this is pretty far forward really.

-at the step in the rear floor? I was thinking of adding an arched crossmember that would go above the rear driveshaft at this location. It would be about 18" or so behind the transmission crossmember ( that is removeable ) to provide support to the middle of the chassis. I think with a little planning this could be a welded in unit that may be able to provide support to the B-pillar of the cage where it would tie into the body. I have to run the exhaust, fuel, and brake lines through this area too. It would also be close to the attachment point for the triangulated upper frame side control arm mounts which I think will be important on the longer LJ length frame rails?

-somewhere slightly behind the rear axle. This would be for rear floor support along with providing a mount for the front of the fuel tank. This would also be in the same area as the rear air bag mounts and shock mounts to provide a little more structure in that part of the frame.

-at the rear bumper. I am trying to design a rear bumper crossmember assembly that integrates the rear body mounts, a tube crossmember for a swaybar, a receiver hitch, and a rear 'bumper' of sorts to protect the body. Oh...and it needs to provide a mount for the rear of the fuel tank....

Think that will give me enough support in the long chassis?

I am still very much on the fence about tying in the cage mounts solidly to the frame. I don't think I want to go all uni-body buggy spaceframe on this vehicle. I think the body and cage tie-in mounts will have to be isolated at this point....

Fun stuff. Once I get some better measurements on the frame I will posts some pictures from Solidworks. I am trying to design the frame in sub-assemblies so that I can just weld in the computer cut crossmembers to the main frame rails once I have the chassis main rails welded up. I finally found a decent solid model of an LS engine so I can computer design the engine mount subframe assembly. The transmission crossmember will probably have to be designed on the fly once I get some parts and see how the clocking on the NP205 ends up.