CharlieNorth

Well-known member

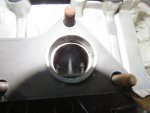

Next step up front with this will be to build the headers. These will be long tube stepped 3-1. I bought a pair of flanges from RRE last fall who claim their flanges are same as port and CNC machined, these are flame cut, not machined. Unfortunately their port size is for 1 7/8 tube where these engines are best with 1 5/8 OD tubing which offers the proper ID for the ports. At least they are simple round ports such that I have material coming that I will machine stubs to step down to the proper size. Unnecessary time waste but I am not in the mood to machine a set of flanges for this project. I make plenty of them for complex port shapes that I was hoping to buy simple ones.

When I was first planning these headers I felt there was plenty of room, but once I have the lower steering column, starter with wires and the front propshaft in place, it gets tight in there. In some ways buying a set of Nissan headers might not have been wrong, but I was not finding any that looked to have mandrel bent tube.

This Pajero has a custom single 2 1/2 exhaust under it, quite well made at that, they used a Flowmaster muffler. I am giving thought to finding a path on the left side to snake a dual exhaust around the T-case and back under this. I have an unused Flowmaster sitting here and plenty of stainless tube and bends. We will see what happens.

When I was first planning these headers I felt there was plenty of room, but once I have the lower steering column, starter with wires and the front propshaft in place, it gets tight in there. In some ways buying a set of Nissan headers might not have been wrong, but I was not finding any that looked to have mandrel bent tube.

This Pajero has a custom single 2 1/2 exhaust under it, quite well made at that, they used a Flowmaster muffler. I am giving thought to finding a path on the left side to snake a dual exhaust around the T-case and back under this. I have an unused Flowmaster sitting here and plenty of stainless tube and bends. We will see what happens.

Last edited: