You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pro-Rig V2.0 - Home Built Compact Composite Pop-up

- Thread starter CoyoteThistle

- Start date

CoyoteThistle

Adventurer

Must be some updates by now!?

Well, precious little to report actually. Life and work getting in the way of progress lately.

Did get out to the desert to see some of the "super bloom". Good stuff.

Everyone is enjoying the flowers.

Would have been a perfect trip for the camper. Better get back to it!!

CoyoteThistle

Adventurer

Made a little progress today!

Got the first seat/hatch in finally. Pretty happy with it. One down, one to go...

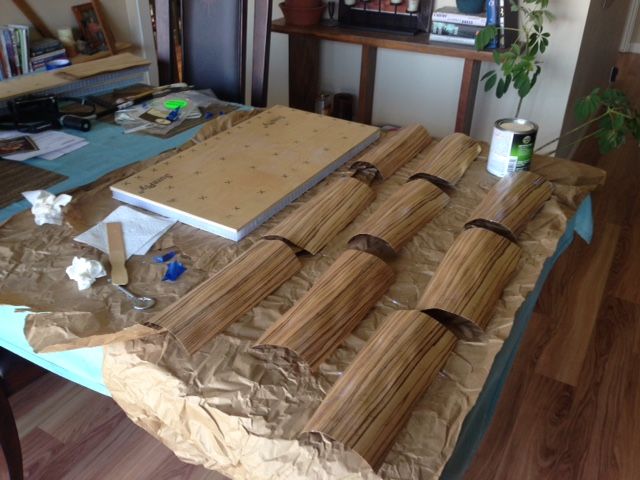

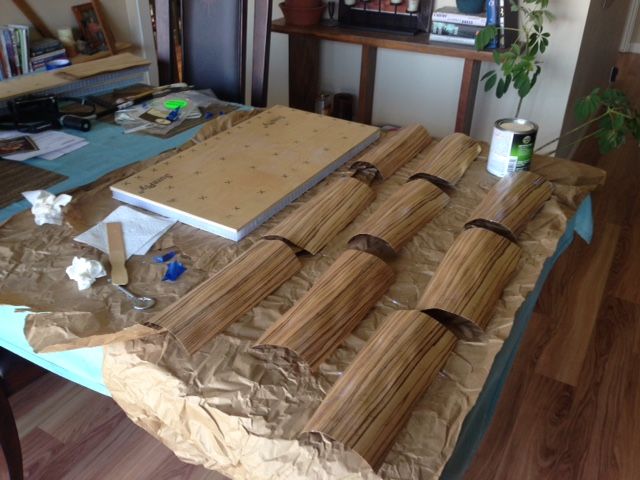

Also took a big leap and went for it with the wood veneer on the table. We chose zebra wood. Edges will be trimmed in dark walnut.

Brushed on the contact cement and let it sit for about an hour. The veneer curled up during this process.

It went on flat and seems to have stuck well. Getting the pieces lined up was a little nerve wracking - only get one chance to line it up and stick it. Turned out pretty cool!

Not sure what type of finish we'll do yet. Want to bring out the contrast in the wood. Maybe some sort of oil then an epoxy finish for durability? Any thoughts appreciated!

Got the first seat/hatch in finally. Pretty happy with it. One down, one to go...

Also took a big leap and went for it with the wood veneer on the table. We chose zebra wood. Edges will be trimmed in dark walnut.

Brushed on the contact cement and let it sit for about an hour. The veneer curled up during this process.

It went on flat and seems to have stuck well. Getting the pieces lined up was a little nerve wracking - only get one chance to line it up and stick it. Turned out pretty cool!

Not sure what type of finish we'll do yet. Want to bring out the contrast in the wood. Maybe some sort of oil then an epoxy finish for durability? Any thoughts appreciated!

mhiscox

Exp. Leader Emeritus

Paul finished the zebrawood veneer on the XV-JP's cabinets with tung oil:Not sure what type of finish we'll do yet. Want to bring out the contrast in the wood. Maybe some sort of oil then an epoxy finish for durability? Any thoughts appreciated!

"I have progressively finer wet sanded with tung oil the woodwork and the time spent doing it shows...I am pleasantly surprised on the richness of the grain and the colors...In person, it looks even better..."

The finish held up fine during my use of the camper.

More at http://forum.expeditionportal.com/threads/51254, post 428 ff.

CoyoteThistle

Adventurer

Oh, that's an epic finish. Looks awesome. I'll try the tung oil.

Figures that more sanding is involved though :squint: I'm starting to think about 75% of my total time on this build will be sanding before all is said and done. So it goes...

Figures that more sanding is involved though :squint: I'm starting to think about 75% of my total time on this build will be sanding before all is said and done. So it goes...

Woodstockz

Member

I was in Borrego last week. Where did you see the big horns?

CoyoteThistle

Adventurer

Yep, table will be hinged. The two side pieces will fold up and lay flat on top. Hinges are double pin type and mounted on top. They are flush when open and allow full 180* flip. Hoping the side pieces won't need additional support underneath.

That just made me think, I should probably veneer the undersides of the side pieces since they will show when folded over. Add it to the list...

Bighorns were in Coyote Canyon (before first crossing) towards sunset. They were up high on the ridge looking at the chaos of humans below. Eventually some yahoo decided to climb up for a closer look - of course this scared them away. Was pretty neat though, five sheep in all. They looked really fit and healthy.

That just made me think, I should probably veneer the undersides of the side pieces since they will show when folded over. Add it to the list...

Bighorns were in Coyote Canyon (before first crossing) towards sunset. They were up high on the ridge looking at the chaos of humans below. Eventually some yahoo decided to climb up for a closer look - of course this scared them away. Was pretty neat though, five sheep in all. They looked really fit and healthy.

timholmesjr

New member

Where did you get the pulls. They look great and are functional.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

CoyoteThistle

Adventurer

Where did you get the pulls. They look great and are functional.

The pulls on the cabinets are from Amazon - bunch of different styles there to choose from. Seem like they will work well.

Pulls on the seat hatches are Amazon as well - Uxcell makes those IIRC. Like them too.

CoyoteThistle

Adventurer

Busy weekend pro-riggin'

Lots of cutting aluminum, more painting and, what else, more sanding!

Roof is getting close to completion. Aluminum channel all the way around the inside and Al end pieces to cover the exposed core.

Al channel will hold the bulb seal like so

Hoping this will be sufficient to keep the water and dust out.

Interior is getting close to being kind of complete.

Bathroom side

Potty will go at right under the medicine cabinet.

Kitchen side

Good news is I'm done with the cabinet doors. Hated that part of it. I like the overall look though and it should be functional.

Pink spot in the floor in the last photo is the shower pan. Need to figure out a low profile shower grate - I've got about 3/4-inch of height to play with. Preferably something that can be pulled out and used for outside showering and is durable enough when the shower is used as the "mud room" - taking off ski boots, muddy shoes, etc.

Only one more piece of paneling to cut - need to make the floor/cover for the shower area.

Then the flooring can go in. I think we settled on vinyl planks - TrafficMaster Allure - Teak. Seems like there is some concern with using vinyl planks in non climate controlled environments (shrink-swell with cold and heat) but many seem to have used it successfully. Any experience here?

Lots of cutting aluminum, more painting and, what else, more sanding!

Roof is getting close to completion. Aluminum channel all the way around the inside and Al end pieces to cover the exposed core.

Al channel will hold the bulb seal like so

Hoping this will be sufficient to keep the water and dust out.

Interior is getting close to being kind of complete.

Bathroom side

Potty will go at right under the medicine cabinet.

Kitchen side

Good news is I'm done with the cabinet doors. Hated that part of it. I like the overall look though and it should be functional.

Pink spot in the floor in the last photo is the shower pan. Need to figure out a low profile shower grate - I've got about 3/4-inch of height to play with. Preferably something that can be pulled out and used for outside showering and is durable enough when the shower is used as the "mud room" - taking off ski boots, muddy shoes, etc.

Only one more piece of paneling to cut - need to make the floor/cover for the shower area.

Then the flooring can go in. I think we settled on vinyl planks - TrafficMaster Allure - Teak. Seems like there is some concern with using vinyl planks in non climate controlled environments (shrink-swell with cold and heat) but many seem to have used it successfully. Any experience here?

Similar threads

- Replies

- 33

- Views

- 4K

- Replies

- 44

- Views

- 8K

- Replies

- 0

- Views

- 565

- Replies

- 1

- Views

- 419