Well, onto version 2.0 of the slosh-proofer ultra 2000....

When I was making the 1st version RIGHT as I was punching the hole for the vent I had another idea. Dang it. I hate that. So, I started over on the top cover gasket.

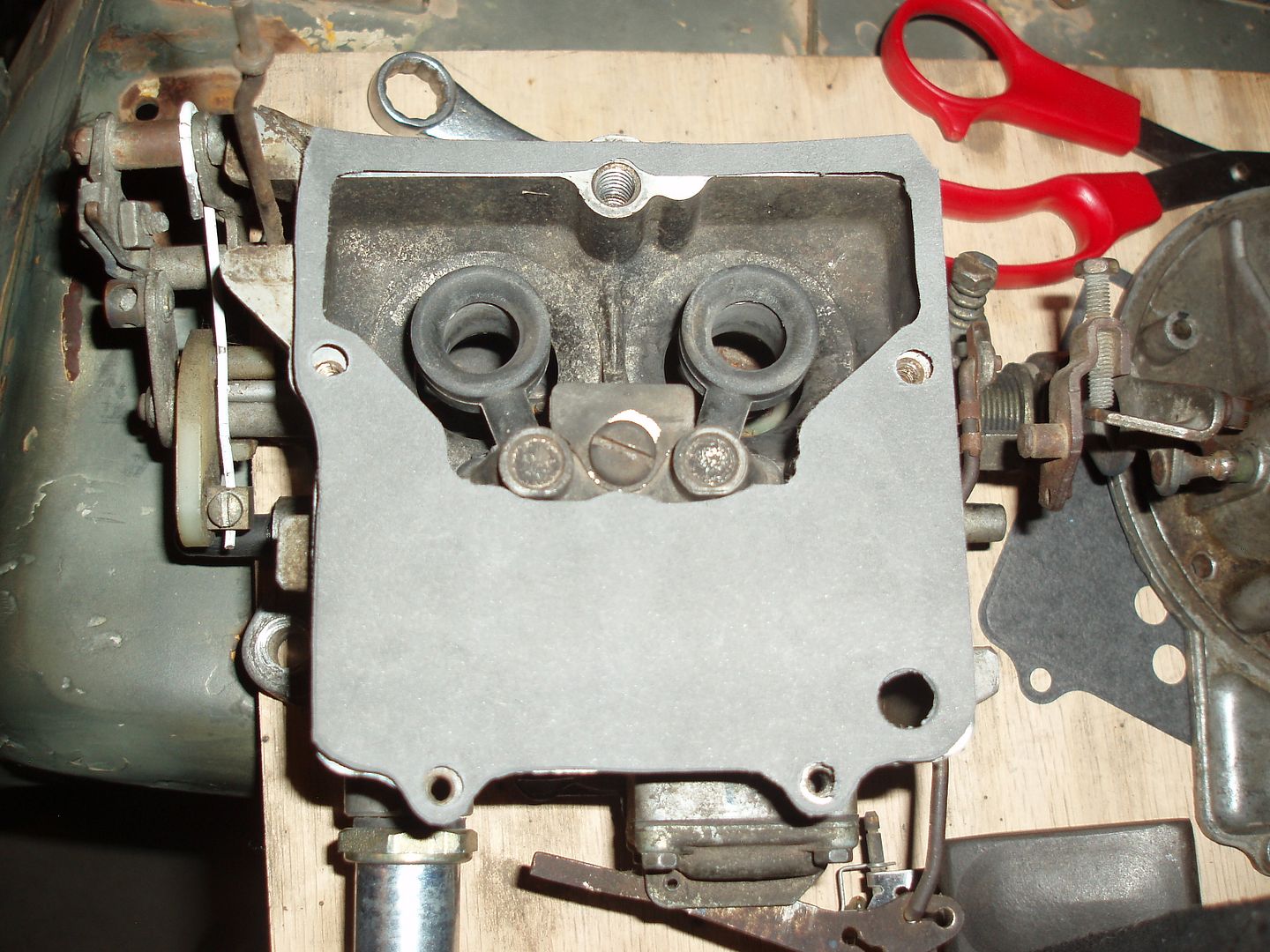

Here is the current version and how it installs. The new improved idea is that with the vent in this location it will maximize the ability of the top cover gasket to prevent the fuel from washing out the vent in the most situations possible. The hole is now in the furthest location possible from both the vent and the float needle. This should hopefully slow the fuel slosh down as much as possible. The high pressure fuel ( all 5-10psi or so ) has to go out of the needle, into the bowl, travel to the other side of the bowl, though a single 9mm sized hole and back across the top of the gasket out the vent tube.

Here is the bottom of the top cover. Good thing I didn't use my original version 1.0 gasket since the hole would have been up against that square flat section at the front of the bowl. You can see that the fuel will kinda have to worm its way from one side of the bowl to the other.

Here are some new vent tube attachments I turned on the lathe tonight. The one of the right is just a short plug with a light press fit. The one of the left is both an extension to a restriction. The factory vents are approximately 0.390" in diameter. The new version has a 0.125" or 1/8" hole. It is also extended up as high as possible for my low profile carb plenum.

The top cover should now act as a baffle for not only nose up situations, it should also function as a baffle for side to side situations. With the hole in the gasket on one side and the vent on the other it should work equally well in both the right and left direction.

When tilting to the drivers side down the vent tube will be high and the baffle low which should prevent raw fuel from sloshing out into the primary. The bowl would have to fill to the point that the bowl level was above the vent tube which I think would almost be impossible.

When tilting to the passenger side down the vent tube will be low BUT the hole in the baffle will be high. The fuel bowl hill have to fill to the point that fuel comes out the gasket hole ( VERY full ) and then the fuel has to run across the top of the gasket and out the extended and reduced diameter vent tube.

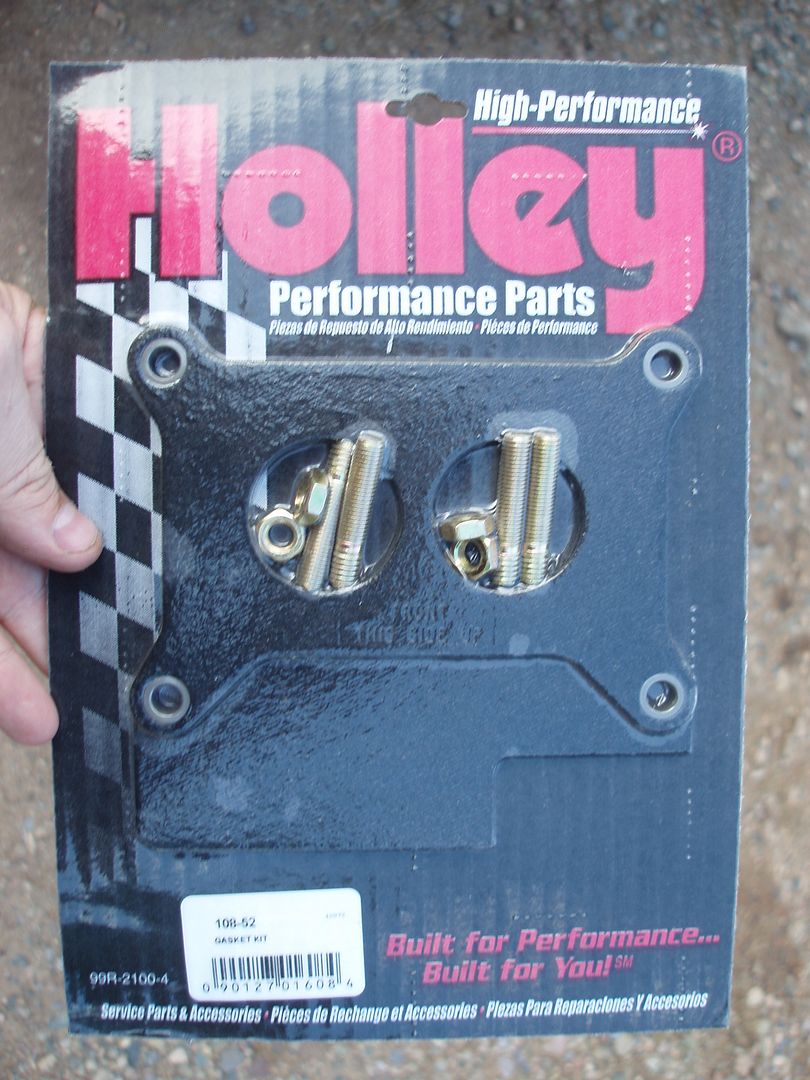

I used one of these thick heat isolating gaskets to mount the carb this time. I hope this will help keep the fuel in the bowl cooler and keep it from evaporating at high engine temp in hot weather when I shut off the engine. There is a small amount of fuel pressurized in the feel line from the fuel pump to the carb, but I have seen this all used up ( refilling the bowl with the engine off ) and the fuel bowl almost depleted of fuel. This is one fairly common cause of hard starts in hot weather....

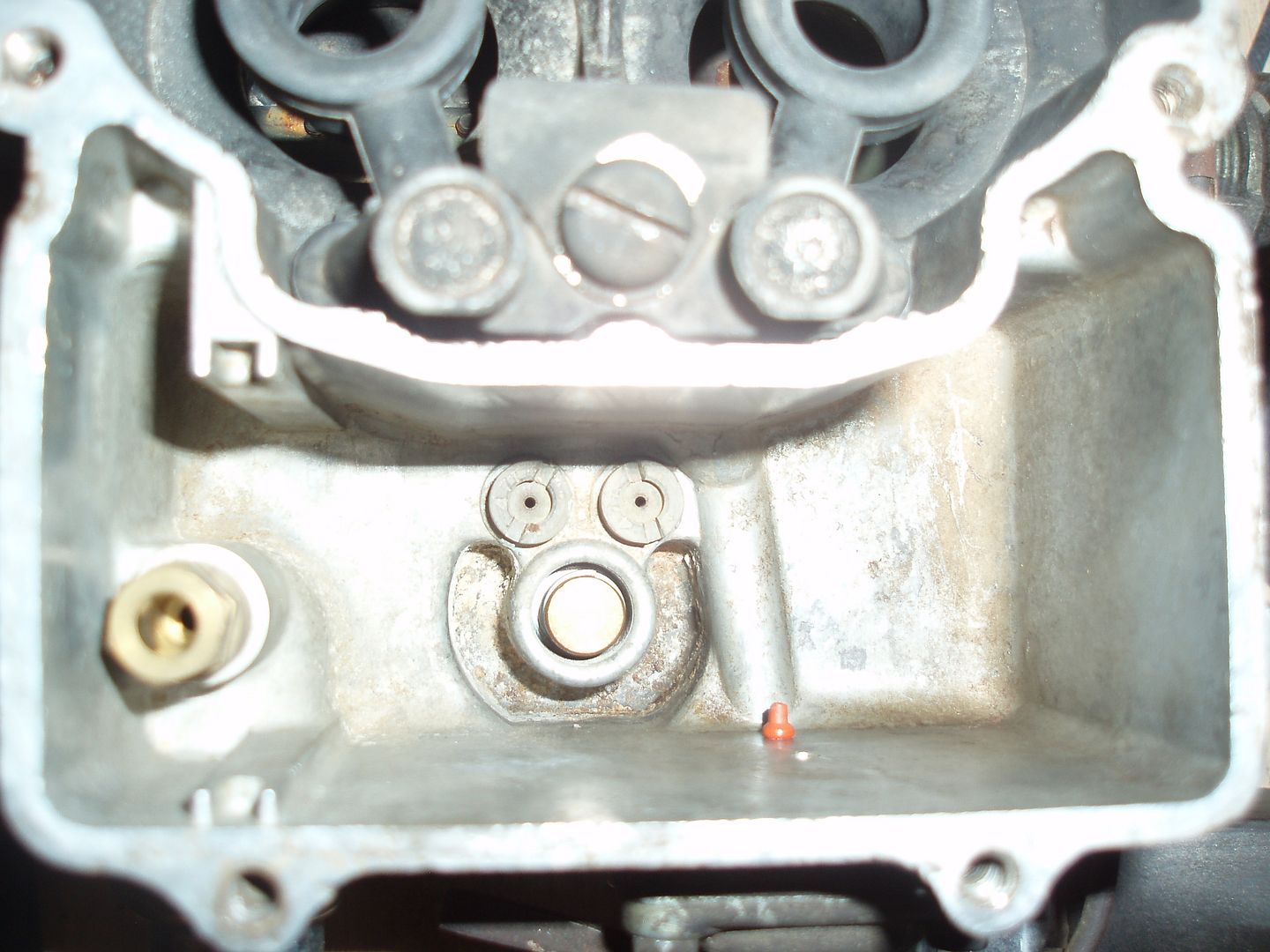

A picture of a autolite/motorcraft 2100 fuel bowl with the float removed. Fuel needle seat on the left. The two main jets in the bottom. The power valve feed just slightly ahead of the jets. The jets are recessed in the bottom of the fuel bowl along with the power valve. I think this is one of the main reasons that the autolites tend to work so well.

I lost one of the screws for the top cover. :homer: Now I have an excuse to get some nice new ones....