luthj

Engineer In Residence

Flange adapter?

Yeah, I will probably go that way. I was going to try and avoid any CNC lathe/mill parts, but an adapter will be simplest.

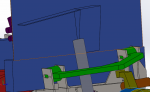

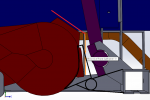

I am working on the front diff mount. This area is pretty tight with the rack positioning. After measuring the diff housing, I think a bracket bolted to the case mounting flange will work. Something like this. I can probably incorporate one of the support with the DS rack mount. Clearance is around 12", which should leave enough room for bracket and .4" clearance.

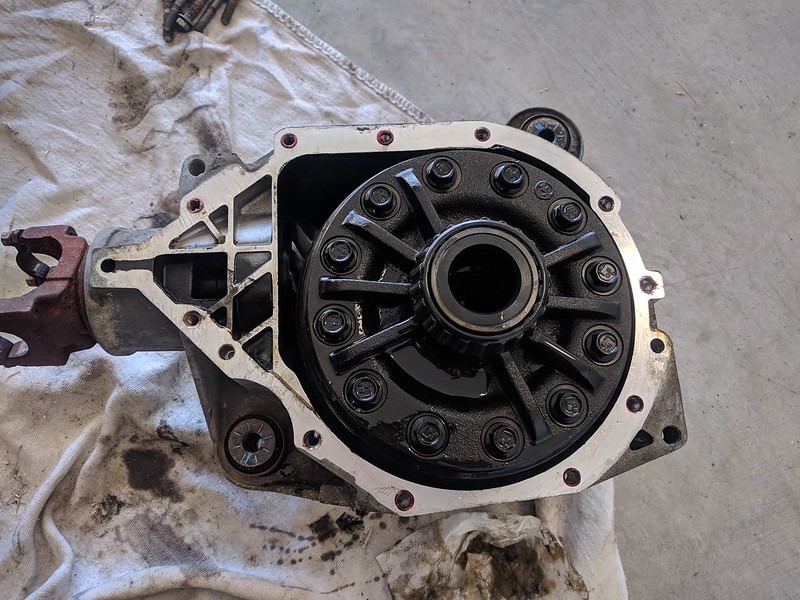

Unfortunately the outer edge of the case is not a flat contiguous flange. Should make for interesting geometry. If gaskets are made for these, I will just by a gasket and scan it. Otherwise I will probably need to split the case, and take a tracing of the bolt locations. I think picking up three bolts will work, but I will aim for 4.

IMG_20190126_123201 by J Luth, on Flickr

IMG_20190126_123201 by J Luth, on Flickr IMG_20190126_123306 by J Luth, on Flickr

IMG_20190126_123306 by J Luth, on Flickr

IMG_20190127_111337

IMG_20190127_111337 IMG_20190127_111356

IMG_20190127_111356 IMG_20190127_113654

IMG_20190127_113654 IMG_20190127_115733

IMG_20190127_115733