...

@thjakits:

What do you want to achieve with such toy motors?

They are designed to work for a few races and not to last for 100th thousand of miles with long service interval.

The power of 6x37 kW = 222 kW = 302 hp would be at the low end, but the resulting torque at the wheels of 6x 1630Nm = 9,780 Nm is extremely bad for the Terraliner with a weight of 18 t (metric).

Even my old MAN KAT has a maximum torque at the wheels of about 984 Nm * 2.5 * 6.37 * 1.07 * 6.734 * 1.59 = 179,526 Nm. This means that it has a pulling power from standstill of about 18 t (metric) without burning a clutch, and even that is not enough in some situations.

Regarding necessary power when I do the calculation for my truck I come to the result that I need about 300 kW to do a 3 % incline with constant speed of 80 km/h, which is pretty much that what I get currently. For a 6 % incline and same speed I would already need about 430 kW. On flat surface I need about 170 kW power at a speed of 80 km/h.

Of course Terraliner shouldn't be like a brick as our KAT. For my calculation I took a drag coefficient of 0.6 and a frontal car area of 10 sqm. A drag coefficient of 0.4 would reduce the power on flat surface for 80 km/h to about 154 kW. Bringing down the weight to 12 t would reduce the power to 113 kW.

Shouldn't such a future concept try to save weight as much as possible?

This will also allow to reduce weight on a lot of points of the chassis construction and makes the vehicle more off-road capable.

For a serial hybrid the continuous power of the generator should output at least 1.5 times the continuous power for maintaining highway speed to be able to recharge the battery. As I wrote earlier two of the Jenoptik units would be ok to get enough power. Because of a large battery bank with at least 100 kWh I see no need for an extra generator just for supplying house power. This all is additional weight and room.

In my opinion a gear box with at least 2 gears for the electric motors makes sense, because there is either to low torque at the wheels or the rpm of the electric motor is more than 10,000. It is right that synchronous electric motors deliver torque from standstill and can do high rpm, but the best efficiency is normally in a range of 2000 - 6000 rpm.

For me the biggest question is, whether Terraliner with 10 m length, 18 t weight and loaded with so many features is the way to go. At the moment I don't see how all this features can be packed into the available 10 * 2.5 * 4 = 100 cbm room without making compromises on living and storage room. Especially the last is missing on a lot of expedition vehicles. The vehicles are fully loaded with technical features, but there are only small lockers available for personal cloths and other items. In reality there is even less room available because most of the lowest 0.5 - 1 m is lost to wheels and chassis.

Design and feature list is one point, but converting this to a real construction is a very complicated task, which cannot always be completed. I am sure some features will have to be dropped. Better make a clear priority list first in order not to get lost in the details.

Hi

egn,

As always, great to hear from you. Here are some questions, which you are in a particularly good position to answer, given your practical experience driving a large motorhome in unusual conditions, for instance, up a creek bed in Albania....:sombrero:

***********************************************

1. The TerraLiner's Center-Line Clearance?

***********************************************

What would you say should be the ideal center-line clearance of the TerraLiner? 50 cm? 60 cm? or more?

***********************************************

2. Portal Axles? Blue Thunder's Center-Line Clearance?

***********************************************

If you think the center-line clearance should be more than 60 cm, then you would probably favor portal axles, correct? Do you think that the TerraLiner should have portal axles? If not, why not?

It would be great to have your feedback on this particular issue, because it affects the design of the "camper box" of the TerraLiner, very much. Higher centerline clearance, means the tubular space frame starts higher, which might also mean that the camper box floor has to start higher. So having a recommendation from you regarding "ideal" and/or sufficient center-line clearance would be greatly appreciated.

Have you driven many deeply rutted roads with

Blue Thunder?

Has

Blue Thunder ever come close to getting stuck, because its center-line clearance was not sufficient?

***********************************************

3. Haf-E's 3 Electric Motor Proposal: Same as Oshkosh

***********************************************

Previously you have made it clear that you favor straight axles, and not independent suspension.

So do you also favor

Haf-E's suggestion: 3 separate electric motors, driving three straight axles via mechanical differentials? I am personally very strongly inclined in this direction right now. But on one side

thjakits favors hub motors, while on the other,

dwh favors the idea of just one big electric motor, perhaps driving a Tatra backbone tube. So what is your current thinking on this question? Clearly, you seem to be against hub motors, probably for the same reasons that

Haf-E and

optimusprime are against them: hub motors will not be protected from severe vibration and shocks on corrugated bad roads like the Tanami Road in Australia, or the G219 in Tibet.

It's worth noting here that Oshkosh's Propulse hybrid system is set up in exactly the same way as proposed by

Haf-E. The relevant pdf is at

http://www.oshkoshcorporation.com/pdfs/Oshkosh_ProPulse_drive_brochure.pdf , and is very much worth reading and quoting in full:

Populse drive technology is unmatched in its ability to power severe-duty trucks. It is the only operational system that claws through the most rugged terrain, keeping pace with armor as it delivers the environmental and economic benefits of a hybrid electric drive system.

ProPulse ushers in a new generation of severe-duty trucks. It’s ideal for tactical trucks, homeland security vehicles, disaster relief, and peacekeeping missions. It’s engineered from the ground up to take on the challenges of military service. And it’s no surprise that this technology comes from the one company who builds the toughest, most reliable, most technically advanced trucks in the world – Oshkosh Truck.

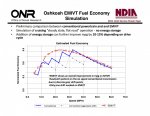

ProPulse increases fuel economy up to 40 percent because the diesel engine in the system continuously runs at optimal rpm — significantly more efficient than the maximum rpm usually needed for highway speeds and full payloads. Emissions are also reduced, meeting current and proposed EPA requirements. And the on-board generator offers enough electrical output to power a residential block, airfield,hospital, commandcenter, communications equipment and much more.

There are no batteries to maintain or replace. Less fuel is needed over the life of the truck. The full electrical system lowers torque throughout the drive train, reducing wear and tear on the truck. And the modular design requires fewer spare parts. All of which increase the value of the vehicle by reducing the life-cycle costs.

Propulse allows for a smaller logistics footprint, increasing the mobility and deployability of fighting forces. Lower fuel requirements mean less fuel to transport, while on-board power eliminates the need for cumbersome generators to power field operations.

Energy Storage Unit

In addition, increased readiness is achieved through improved diagnostics that trend performance and track maintenance over the life of the vehicle, predicting maintenance needs more accurately than ever before. The diagnostics also offer real-time operating information and help keep your truck ready for action. And the easy to maintain system has fewer moving parts, no batteries and many commercially available components.

The ProPulse electric drive technology and its diagnostic systems help crews identify issues and keep vehicles at top performance. Advanced safety technology allows the user to discharge all stored energy from the truck, so maintenance crews can work in complete safety. This Safety Maintenance Mode eliminates the need to have specially-trained technicians performing routine vehicle maintenance.

ProPulse ushers in a new generation of severe-duty trucks. It’s ideal for tactical trucks, homeland security vehicles, disaster relief, and peacekeeping missions. It’s engineered from the ground up to take on the challenges of military service. And it’s no surprise that this technology comes from the one company who builds the toughest, most reliable, most technically advanced trucks in the world – Oshkosh Truck.

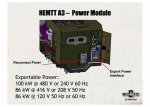

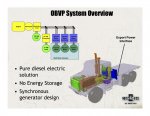

The simplified drive train of ProPulse delivers more power. The diesel engine drives a 335 KW generator that delivers power to electric motors dedicated to each differential. This direct transfer of power eliminates the need for the torque converter, transmission, transfer case, and drive shafts, making the entire system more efficient with fewer moving parts.

The energy storage unit provides extra power for acceleration, deceleration and other functions, and is capable of receiving much higher regeneration energy for highly responsive braking. It delivers the power the truck needs and still maintains fuel efficiency.

The ProPulse system provides the power to traverse the most demanding terrain, and put payloads and electricity where you need it most. It is slated to power the new HEMTT A3, the next generation of air- transportable tactical trucks. And it’s one more way Oshkosh is transforming severe-duty trucks for modern military forces.

I highlighted the most relevant sentences in blue.

Note, however, that although the PDF does not explicitly discuss this, Oshkosh seems to be implementing its TAK-4 Independent Suspension system across its entire product range, including its diesel-electric hybrids. This suggests that there is no "intrinsic" or "necessary" conflict between the three E-motors solution, and IS. The three E-motors do not have to be driving three straight axles.

Like you,

Haf-E,

thjakits, and a few others, I am also now inclined towards straight axles. But I would still like to hear from

campo, about why he strongly favors Independent Suspension for the TerraLiner.

***********************************************

4. The TerraLiner's Power Requirement

***********************************************

According to your calculation, 430 KW should be

very sufficient for the electric motors, which is similar to

thjakits' rough-ballpark figure of 420 KW for the electric motors. If the electric motors need 430 KW, then wouldn't the diesel engine have to be 645 KW, if the power ratio is 1 to 1.5? In terms of horsepower, that's an 865 HP diesel engine! But two Jenoptik generators would only produce, combined, 120 KW + 120 KW = 240 KW. See

http://www.jenoptik.com/en_20083_power_units and

http://www.jenoptik.com/en_30134_auxiliary_power_units .

So I am not entirely clear what your argument is here. Are you saying that 300 KW is enough? Or that 430 KW would be better? Is your argument that driving up a 6 % incline for an extended period is very unlikely, so 420 KW or 430 KW is totally unnecessary? However, even 300 KW would not be covered by two Jenoptik generators, which produce only 240 KW. Are you saying that 240 KW should be enough, even though this is less than the current power requirement of

Blue Thunder?

However, it is very interesting that you favor the idea of two side-by-side identical generators, instead of one big generator. Any particular reason why? Distributing the weight on two different slide-out trays? Redundancy?

***********************************************

5. Size of the Electric Motors

***********************************************

Now if you favor

Haf-E's proposed solution, would you have all electric motors be the same size? Or would you have different electric motors be different sizes? And if so, why?

For what it's worth, the axle format that I have settled on is a standard tandem design as per

Blue Thunder: one axle in front, two clustered in the rear. And I am no longer worried about the "breakover" angle, because so many commercial overlanding vehicles have such bad breakover angles. The vehicles used by

Dragoman,

Oasis,

Odyssey, etc. all have breakover angles much worse than the breakover angles in the 6x6's posted earlier in the thread. For further discussion and lots of images, see posts #1027 and #1028 at

http://www.expeditionportal.com/for...edition-RV-w-Rigid-Torsion-Free-Frame/page103 , and posts #1068 to #1080 at

http://www.expeditionportal.com/for...edition-RV-w-Rigid-Torsion-Free-Frame/page107 and

http://www.expeditionportal.com/for...edition-RV-w-Rigid-Torsion-Free-Frame/page108 .

***********************************************

6. TerraLiner Weight Reduction

***********************************************

As for overall weight, my engineering friends are working on those calculations right now.

Remember, because this is a concept vehicle, I can do crazy things like specify that the tubular space-frame will be made out of titanium, perhaps created via the new technology of titanium 3-D printing -- see

http://www.3ders.org/articles/20130...st-3d-printed-titanium-fighter-component.html . This was suggested by

thjakits in post #825, at

http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page83 .

Furthermore, I can specify that the camper box and pop-up will be made out of carbon fiber. Agreed, weight reduction is critical, and as you suggest, would also have a significant impact on the overall power requirement, as well as the TerraLiner's off-road capability.

Did you see the posts earlier in the thread about the new, all-carbon-fiber trailer, called the CR-1? Posts #865 to #867, at

http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page87 . Or see

http://www.wired.com/2014/04/gct-cr-1/ ,

http://www.gctrv.com/Global-Caravan-Technologies.php ,

http://www.gctrv.com/CR-1-Carbon-Fiber-RV.php ,

http://www.gctrv.com/images/vtour/Salon-vtour/tour.html ,

http://www.gctrv.com/images/vtour/Kitchen-vtour/tour.html ,

http://www.gctrv.com/images/vtour/Bedroom-vtour/tour.html ,

http://www.gctrv.com/images/vtour/Bathroom-vtour/tour.html ,

http://www.gctrv.com/About-Global-Caravan-Technologies-RV-Manufacturer.php , and

http://www.gctrv.com/About-Press.php :

[video=vimeo;88709487]http://vimeo.com/88709487[/video]

A typical 31 foot Airstream Classic Dinette Trailer weighs about 7,174 pounds, whereas the CR-1 is 35 feet long, 7 feet high, and weighs only 6,500 lbs.

In the world of commercial cargo-carrying trailers, Wal-Mart included an all-carbon-fiber trailer made by Great Dane, in its Capstone microturbine-based concept truck -- see

http://articles.sae.org/13507/ ,

http://www.core77.com/blog/material...nels_for_their_supertruck_prototype_27697.asp ,

http://www.dezeen.com/2014/03/07/walmarts-electric-powered-carbon-fibre-truck-concept/ ,

http://www.greencarreports.com/news...cept-truck-the-fuel-efficient-future-of-semis , and

http://news.walmart.com/news-archive/2014/03/26/walmart-debuts-futuristic-truck :

The last video explains the trailer's construction at great length, which involved a technological collaboration between Fiber-Tech and Milliken -- see

http://www.fiber-tech.net ,

http://www.fiber-tech.net/index.php/product-info/product-info ,

http://www.fiber-tech.net/index.php/product-info#Transportation ,

http://www.fiber-tech.net/index.php/showcase , and

http://www.fiber-tech.net/index.php/gallery ; and

http://www.milliken.com/en-us/Pages/default.aspx ,

http://www.milliken.com/en-us/pands/Pages/composites.aspx ,

http://structuralstrengthening.milliken.com/Pages/home.aspx ,

http://structuralstrengthening.milliken.com/Pages/products-renewwrap.aspx , and

http://www.buildingspeed.org/blog/tag/milliken-company/ .

Walmart claims that this is the first all-carbon fiber trailer ever produced, and that the 53-foot long side panels are the largest single pieces of carbon fiber ever manufactured. Wal-Mart trailers normally weigh about 14.400 lbs, whereas this carbon fiber trailer weighs 3000 lbs less, or 11,400 lbs. That's a weight saving of roughly 20 %.

One early, innovative entrant in this market is "Composittrailers" of Belgium, now renamed "Acrosoma", which you can read about at

http://www.reinforcedplastics.com/v...e-composite-trailer-to-a-conservative-market/ ,

http://www.reinforcedplastics.com/view/4666/composittrailer-changes-name-to-acrosoma/ ,

http://www.compositesworld.com/articles/new-lightweight-trailer-delivers-heavy-duty-performance ,

http://trailer-bodybuilders.com/archive/ten-percent-weight-reduction-composittrailer ,

http://www.vdlfibertechindustries.com/?page/5791502/Acrosoma®.aspx ,

http://www.vdlfibertechindustries.com/?page/5793582/Technology.aspx ,

http://www.vdlfibertechindustries.com/?page/5792542/Markets+and+Products.aspx ,

http://www.plast.dk/billeder/Sektioner/Komposit/MicrosoftPowerPoint-JanVerhaegehe.pdf ,

http://www.vdlfibertechindustries.c...flet_Acrosoma_VDL_Fibertech_Industries_EN.pdf , and

http://issuu.com/acrosoma/docs/acr_acrosomapanels_eng_lr?e=3874049/2677937#:

Their trailer with Acrosoma panels weighs 25 % less than an equivalent aluminum or steel model.

For additional initiatives in this direction, see

http://www.diabgroup.com/Cases/Tran...ch-Reefer-Trailer-from-TTT-The-Team-Composite ,

http://www.diabgroup.com/en-GB/Sandwich-technology/Introduction ,

http://www.diabgroup.com/en-GB/Sandwich-technology/Introduction ,

http://www.theteam-hamburg.de ,

http://www.theteam-hamburg.de/pdf/cfrp-zero_emission_reefer_trailer.pdf , and

http://www.theteam-hamburg.de/pdf/TheTeam_Messebrochuere_09-2010.pdf ; and

http://www.lightweight-structures.c...eight-composite-isothermal-trailer/index.html .

***********************************************

7. Abundant Storage Space

***********************************************

As for storage space, I have a few additional tricks up my sleeve. Almost a year ago I

really took to heart all of your thoughts about the problem of designing a TerraLiner to have enough storage space for three or four weeks of boondocking. And not just storage for food, but also enough storage for clothes. A couple full-timing in the TerraLiner will probably want to carry almost as many clothes, and the same variety of clothes, as they would if they had a fixed home. I have been

very conscious of this issue, so don't worry, the TerraLiner is being designed with such considerations very much in mind.

"Compromises" will not be necessary, at least not on paper anyway......:sombrero:

***********************************************

8. Battery Bank Size, and Ultracapacitors

***********************************************

Also, thanks for that estimate of the battery bank size: 100 KW. This is roughly the same as the size estimate that my engineering friends gave.

I have been following

thjakits' lead about "Dual Carbon" batteries -- see

http://www.theatlantic.com/technolo...japan-that-could-spawn-the-next-tesla/362112/ ,

http://www.gizmag.com/dual-carbon-fast-charging-battery/32121/ ,

http://www.extremetech.com/extreme/...e-breakthrough-weve-been-promised-for-so-long ,

http://revolution-green.com/ryden-dual-carbon-battery/ ,

http://powerjapanplus.com/about/news.html ,

http://powerjapanplus.com/battery/equation/ ,

[video=youtube;OJwZ9uEpJOo]https://www.youtube.com/watch?v=OJwZ9uEpJOo [/video]

And of course Ultacapacitors also remain an option:

[video=youtube;LYL6NyU1g3k]https://www.youtube.com/watch?v=LYL6NyU1g3k [/video]

This is a really good video that explains in a clear and simple way the suitability of Ultracapacitors in a transportation application. Ultracapacitors have the ability to be charged very quickly: the bus in this video can fully recharge its Ultracapacitors in just 5 minutes. This also means that the regenerative braking system on this bus -- in which the electric motors become generators when decelerating -- will work more efficiently, because they will not be trying to feed electricity to slow-to-charge batteries.

However, this bus also

does have batteries as well!! The range of the bus on Ultracapacitors is only 3 miles, while its range on batteries is 15 miles. Which suggests that the TerraLiner, too, should probably have a similar combination of batteries and Ultracapacitors. When stationary and boondocking, ideally the TerraLiner's battery bank should keep all camper box living systems going for at least a day, if not longer, without charging. Whereas it would seem that a vehicle that only has Ultracapacitors could not do this; it would need to have its diesel engine running continuously, recharging the Ultracapacitors.

I may be wrong about this, so please feel free to correct me if I am. I am just responding to this video, which seems to lay out the technological options very clearly.

***********************************************

9. Oshkosh UltraCapacitors

***********************************************

It's worth repeating that Oshkosh diesel-electric vehicles use Ultracapacitors made by Maxwell technologies -- see

http://www.dieselpowermag.com/features/1107dp_diesel_electric_hybrid_hemtt_oskosh_a3/#__federated=1 ,

http://www.oshkoshcorporation.com/pdfs/Oshkosh_ProPulse_drive_brochure.pdf ,

http://www.oshkoshcorporation.com/about/tech_innovations~propulse.html ,

http://www.dtic.mil/ndia/2007power/...snasrCopyofJointServicePowerOTC42407Final.pdf ,

http://www.forbes.com/2006/01/30/oshkoshtrucks-fuelcells-trucks-cz_atg_0131osk.html ,

https://www.tecategroup.com/white_papers/badnames/200904_WhitePaper_PowerModules.pdf ,

http://www.hybrid-vehicle.org/hybrid-truck-hemtt.html ,

http://www.maxwell.com ,

http://www.maxwell.com/products/ultracapacitors/ ,

http://www.maxwell.com/products/ ,

http://www.maxwell.com/solutions/transportation/auto ,

http://issuu.com/maxwelltechnologies/docs/auto_brochure/20?e=14613819/10386948 ,

http://issuu.com/maxwelltechnologies/docs/auto_brochure ,

http://www.maxwell.com/solutions/transportation/truck ,

http://www.maxwell.com/solutions/transportation/bus , and

http://www.maxwell.com/about_us/press-releases .

Here is a list of reasons why Oshkosh chose Maxwell Ultracapacitors, instead of batteries -- see

http://www.dieselpowermag.com/features/1107dp_diesel_electric_hybrid_hemtt_oskosh_a3/#__federated=1 :

Why Ultracapacitors Instead of Batteries?

Although Oshkosh selected ultracapacitors in this application, batteries or other storage devices could be swapped in if the situation called for it. A few advantages of ultracapacitors include:

1. They offer increased safety, since the capacitors can be brought down to 0 voltage for maintenance operations.

2. They work well in extreme temperatures ranging from -51 to 125 degrees.

3. Accelerated aging and cycling tests show they last the 25-year life of the vehicle.

4. Round trip efficiency is about 10 percent more than a comparable battery-electric hybrid, due to the ultracapacitor’s ability to recover braking energy.

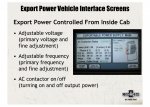

The diesel engine is not mechanically connected to the wheels. Instead, it runs at an optimal rpm range and creates electrical power, which is delivered to the axle-mounted motors. When extra power is required to accelerate the vehicle, ultracapacitors kick in and deliver the burst needed. When it’s time to slow down, the motors in the axles double as generators and replenish the quick-charging capacitors.

A. 340kw generator (PURPLE)

B. 470hp diesel engine (GREEN)

C. 1.9mj ultracapacitors for energy storage (ORANGE)

D. 480 volts ac induction motors (one per axle, 4 total, BLUE)]

Here Oshkosh repeats one of the rationale's for Ultracapacitors also given in the video:

"Round trip efficiency is about 10 percent more than a comparable battery-electric hybrid, due to the ultracapacitor’s ability to recover braking energy."

But I have the sneaking suspicion that boondocking in silence for a few days, without the diesel engine running, and just relying on solar panels to recharge the battery bank, is not part of the Oshkosh A3's design specification..... ...

... After all, the Oshkosh A3 is not a vehicle for living in; it is

not a motorhome. And when it stops somewhere, all systems will shut down, so why would it need batteries? When electricity is needed, say, to power the lights of an airfield, then the diesel engine would be running.

Here is an interesting, more "skeptical" article about battery innovation:

http://cleantechnica.com/2014/06/06/elon-musk-unimpressed-battery-breakthroughs/ .

For the volumetric and weight estimate for the battery bank, I have been calculating on the basis of currently available Lithium-Ion batteries. It's anyone's guess how much smaller or lighter Dual Carbon or Ultra-Capacitors might be, because they are not yet widespread automotive technology.

But again, it may turn out that the ideal solution is not either/or, but rather, both/and, as per the Shanghai bus in the video.

***********************************************

10. Diesel Engine KW relative to Electric Generator KW

***********************************************

egn, notice how the following image from the Oshkosh Propulse pdf would seem to undermine your 1 to 1.5 estimation of the KW power difference between the diesel engine versus the generator.

In this pdf's illustration, the Oshkosh A3's diesel engine is described as 450 HP or 335 KW, which is the same as the stated power output of its electric generator. So too, in

Diesel Power Magazine the A3's diesel engine is stated as generating 470 HP, or 350 KW, while the electric generator produces 340 KW, or just 10 KW less -- see

http://www.dieselpowermag.com/features/1107dp_diesel_electric_hybrid_hemtt_oskosh_a3/#__federated=1 . Does this strike you as a mistake? Or how would you explain what is going on here?

It's worth noting, of course, that the A3's 330 KW of electrical power production is roughly the same as the power needs of

Blue Thunder. Which seems to suggest that the TerraLiner should have a 470 HP diesel engine driving the generator, at a minimum (or two equivalent diesel motors, driving two generators). As I mentioned before, a much smaller and lighter vehicle, Oshkosh's hybrid-electric L-ATV, has a 400 HP 6.6 L engine -- see posts #671 to #673, at

http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page68 . All of this inclines me to think that

campo's estimate of TerraLiner diesel engine size earlier in the thread -- in the 500 HP range -- is probably more nearly right.

***********************************************

11. Ideal or Sufficient TerraLiner Centerline Clearance

***********************************************

In closing, once again it would be really helpful if you could specify an "ideal" or "sufficient" centerline clearance, based on your experience with

Blue Thunder. That would help me and my engineers tremendously....

This is not something that even most automotive engineers could guess, unless they are automotive engineers who work specifically for Mercedes, designing Unimogs. What's really needed is real-world feedback from someone like you,

egn, who has a MAN-KAT 6x6 that has done some interesting things in the field.

Although your MAN-KAT is truly off-road capable, and built like a tank, in many ways it comes closest to the TerraLiner as "model" or "precedent".

Blue Thunder has a rigid, non-flexing frame, for instance, whereas most of the vehicles sold by UniCat or Actionmobil have frames that flex. Now I am not sure whether frame rigidity would help or hurt when it comes to the question of centerline clearance, and driving on deeply rutted roads. Only someone like you could answer this question. Whereas not even those who drive 6x6 UniCats could answer this question, because the frames on their vehicles are so different from the ultra-rigid tubular space frame projected for the TerraLiner.

Indeed, what

is the center-line clearance of

Blue Thunder? I know, it will vary depending on the tires used. But just a rough ballpark range: 50 cm to 60 cm?

All best wishes,

Biotect