How about a thread revilval?

Now that i can just copy and paste IMG code, this will go WAY faster and now i have motivation to do it since i won't have to rewrite and re link everything.

So

Here is some welding I missed early on. I fixed the tire mount to angle it up a bit and added my folding table and 90º latch. Id like to redo the latch to a smaller pin style later..

Ok here we go.

So first I did the tire mount. As you can see the tire leans back a bit. I didn't like that

So I made a cut as close as I could with a cut off wheel

Then took the BFH to it and whalla!

Seemed to level it out..

I still wanted it angled forward a bit tho

So..made another cut in the same spot..

And more BFH time!

And this is how the tire will sit now. I like it.

Welded up the cut. Mark..are you taking notes?? This is how you weld

Next I did the part for the hole for my lock pin. I fabbed up this piece before I left out of boiler 1/4" plate with the cutting torch. Time to weld it on!

Tached on

Welded on!

Again mark..taking notes still?

Welded on the lock pin.

Drilled a 1/2" hole for the pin. Had to file it a tad bigger

And this is how the swing out sits when the pin is down and locked

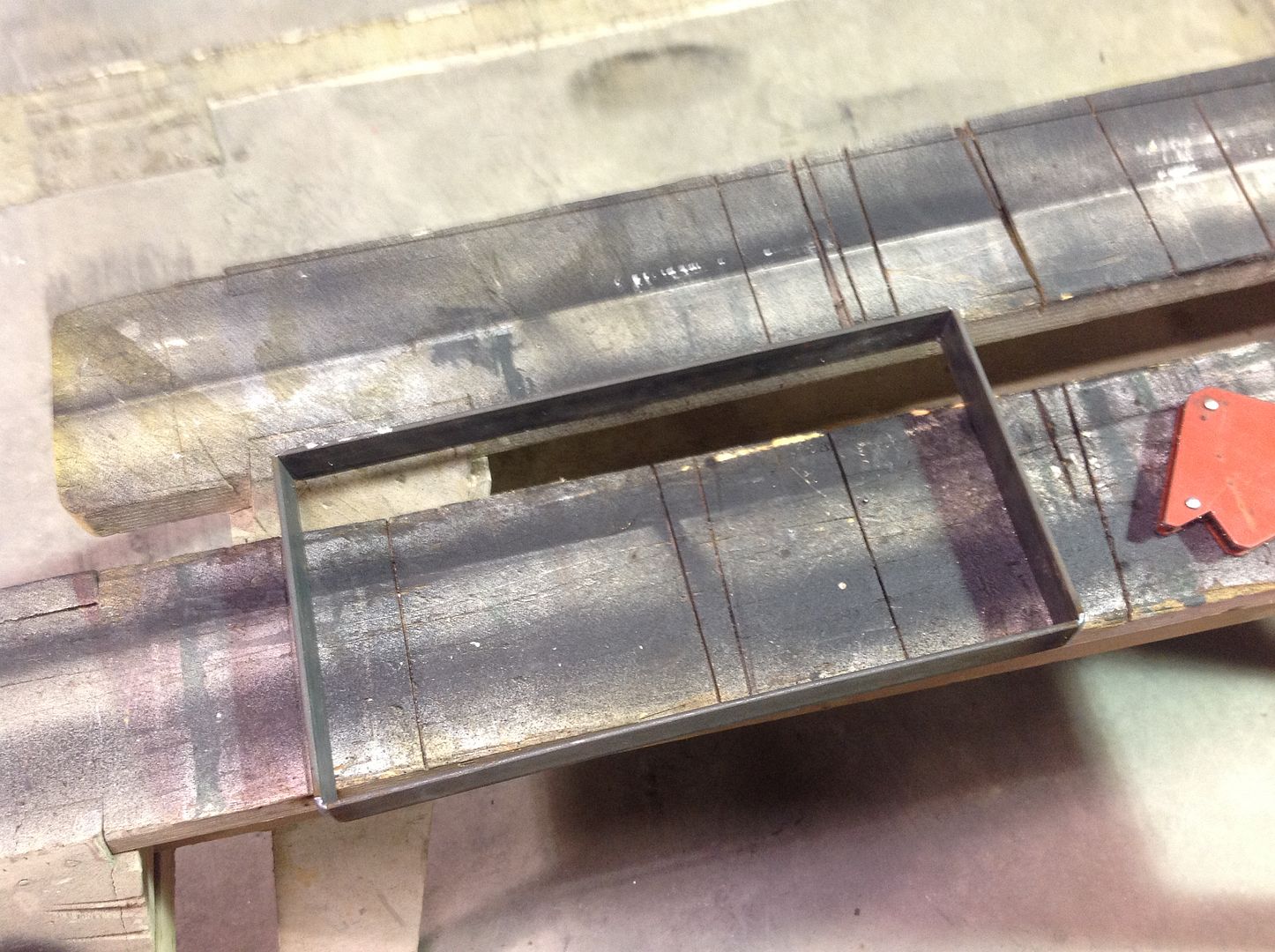

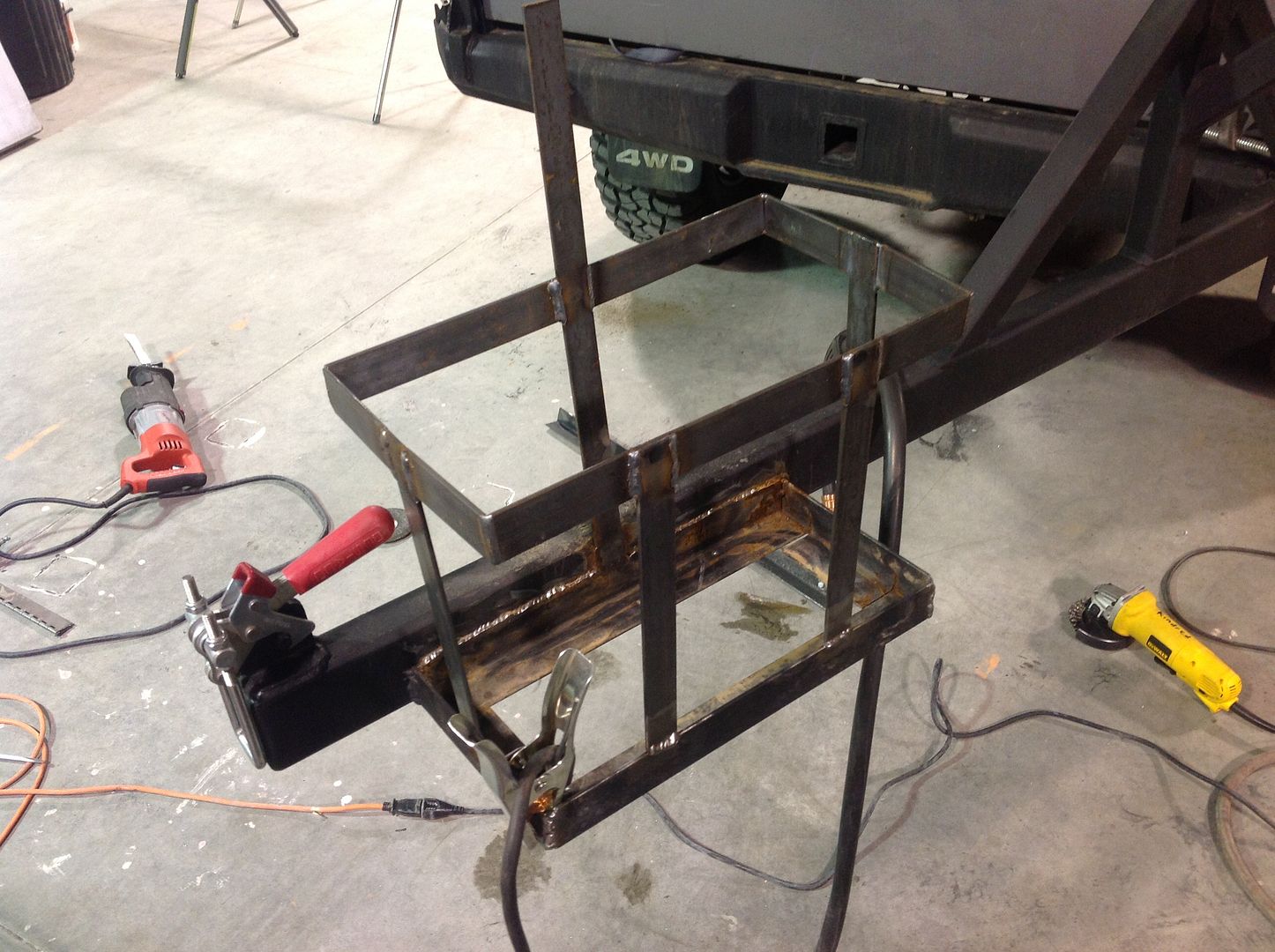

And now the Jerry can mount! I started by making a box 14x7" out of 1.25" strap

Mark..again...keep those notes going..

Then I ended cutting it on the 7" side to weld to the sides of the side posts I had to allow it to be just over 8" wide. Why? Well my Jerry can had expanded from being in the sun and filled with gas. So I needed it wider then my original dimensions. It's no big deal as it fits perfect and the lower part holds it very tight as it is.