rrclassicbt550

Farmer Jon

Rear mount for the long range fuel tank

Alright, I will start with the rear mount.

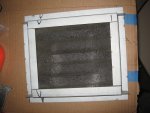

Here is the stock tank and stock mounts.

And here is the LRFT. You might notice the difference between the LRFTs mounting holes and the stock RRC mounting studs. The LRFT mounts are narrower and much further back.

You might not have been able to see it in the previous picture, but the bars for the trailer hitch are in the way of the tank fitting properly.

So....time to bring out the sawzall.

I really REALLY did not want to cut these out, because at the time I was not sure if I would be able to put them back in.

Have a lot more cutting to do with the sawzall to get it to fit.

Going to have to earn that last few inches...

I ended up adding an inch to the outsides of of the two sharpie marks just to be make sure I would have enough room.

Turns out the rear crossmember is double walled and I had to cut through the second wall too to create enough room.

Alright, I will start with the rear mount.

Here is the stock tank and stock mounts.

And here is the LRFT. You might notice the difference between the LRFTs mounting holes and the stock RRC mounting studs. The LRFT mounts are narrower and much further back.

You might not have been able to see it in the previous picture, but the bars for the trailer hitch are in the way of the tank fitting properly.

So....time to bring out the sawzall.

I really REALLY did not want to cut these out, because at the time I was not sure if I would be able to put them back in.

Have a lot more cutting to do with the sawzall to get it to fit.

Going to have to earn that last few inches...

I ended up adding an inch to the outsides of of the two sharpie marks just to be make sure I would have enough room.

Turns out the rear crossmember is double walled and I had to cut through the second wall too to create enough room.