You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"TrailTop" modular trailer topper building components

- Thread starter jscherb

- Start date

jscherb

Expedition Leader

Nice work Jeff. I keep watching this every day. I sure hope this will be picked up by someone so we who are less talented are able to get these pieces. This makes it look fun to build a teardrop camper. Keep up the nice work and thanks for posting up the pics.

Henry

Thanks Henry. It's been fun for me so far

One thing that makes it fun (and accessible to those who think they're less talented than the next guy) is that everything is designed so that only typical hand and hand power tools are needed to successfully build one. It will be possible to build a TrailTop with only a drill, a handheld jigsaw, a 4 1/2" angle grinder plus typical non-power hand tools. Of course other tools can make the work easier, like a handheld circular saw (Skilsaw) for cutting the side panels nicely, but the three I just listed are the minimum I'd recommend.

As I do my assembly with the prototype, I've been working with the minimal set of tools to prove the concept.

jscherb

Expedition Leader

I've been thinking that my next major "tool" purchase should be an industrial sewing machine. I've got lots of ideas for canvas components for trailers, roof-top tents and Jeeps, and I'm getting a bit tired of fiberglass work, so I've been thinking maybe I should branch out into sewing.

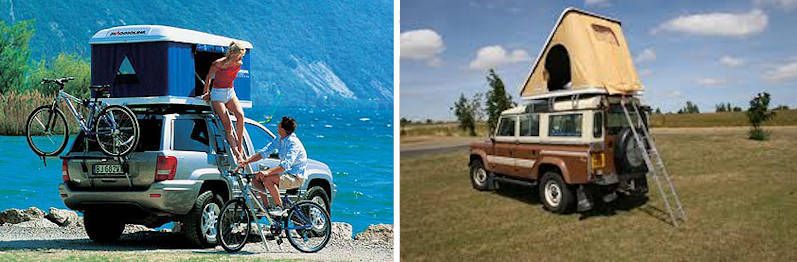

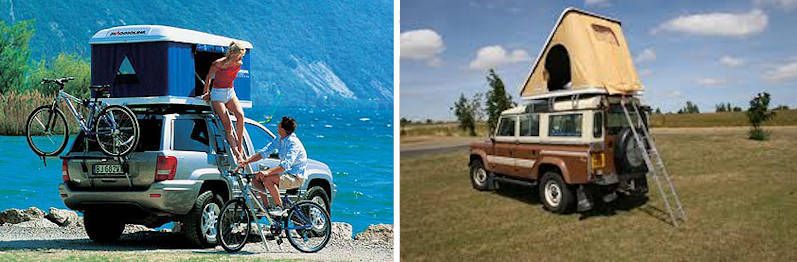

clynn85 and I have been emailing about fiberglass components for clamshell-type roof-top tents recently. A few commercial ones are pictured below, they are available in several styles - on some the roof is hinged, and on others the roof raises vertically:

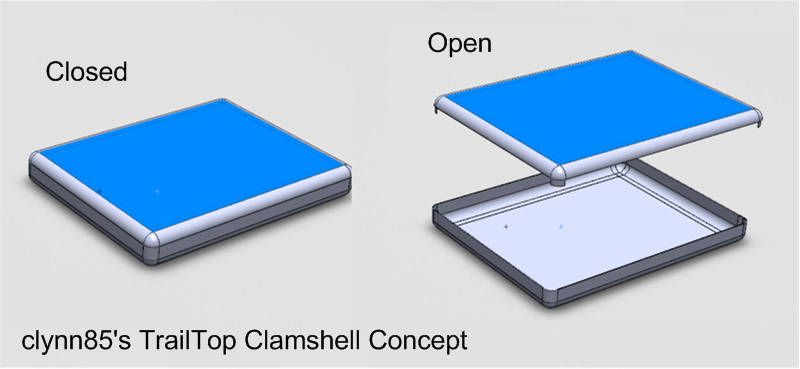

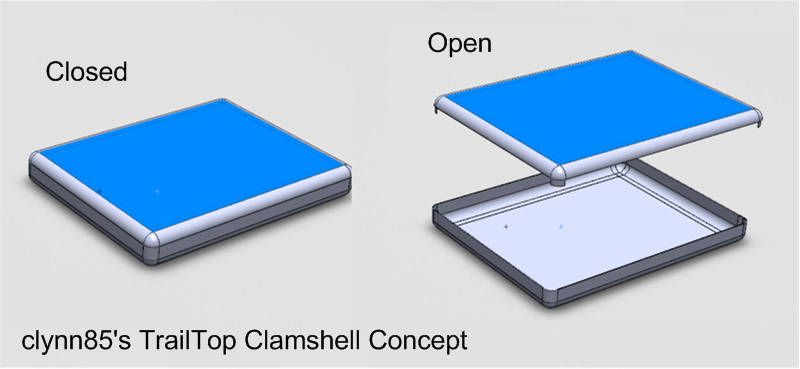

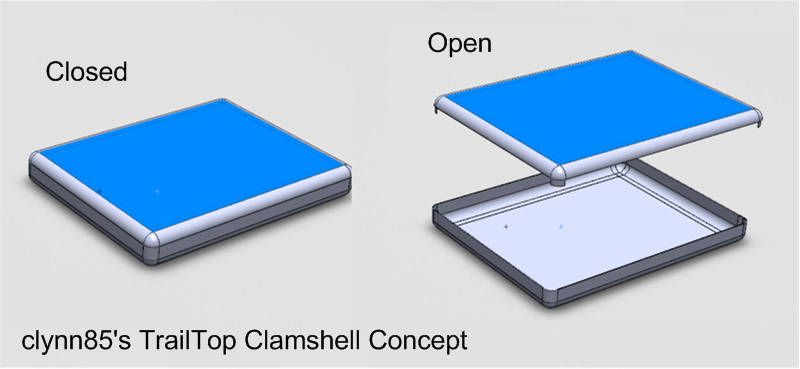

So Carl's concept is to use TrailTop parts to build the clamshell. He sent me some CAD drawings last night:

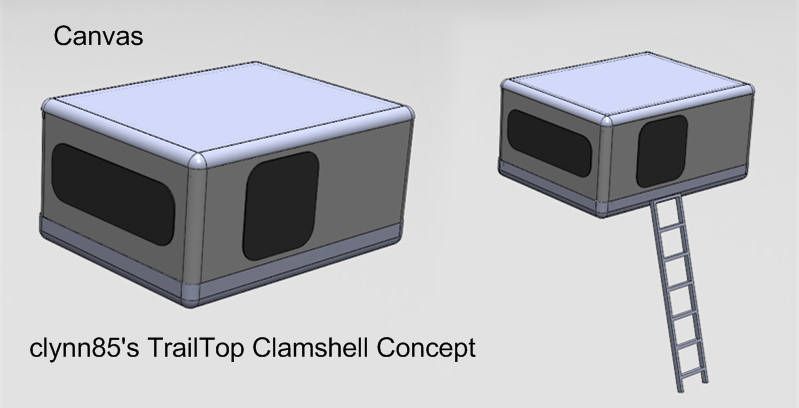

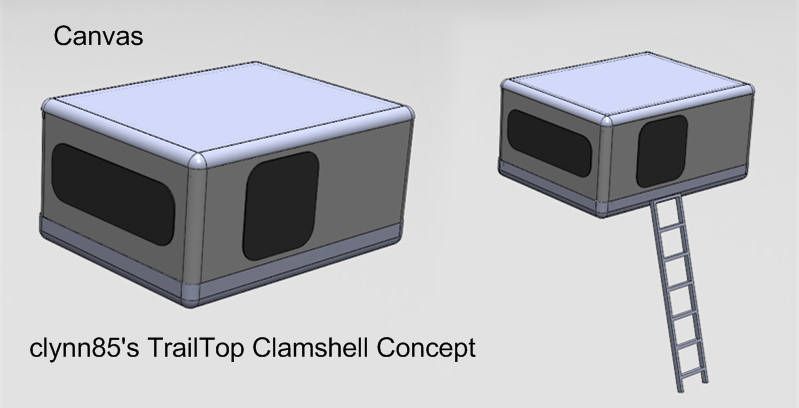

He's also done one showing how the canvas might look:

It seems like a pretty straightforward application of the TrailTop parts, his concept wouldn't be too hard to build. The hinged roof type would be fairly easy - only hinges and some prop rods or gas struts would be required.

The vertical lifting style needs some sort of mechanism for raising the roof vertically. I have no experience with clamshell tents where the roof raises vertically, so I am not familiar with the types of mechanisms they use. Anyone have any good ideas about a mechanism for a vertical roof raise?

Maybe if I get that sewing machine I've been thinking about this would be a good next project...

clynn85 and I have been emailing about fiberglass components for clamshell-type roof-top tents recently. A few commercial ones are pictured below, they are available in several styles - on some the roof is hinged, and on others the roof raises vertically:

So Carl's concept is to use TrailTop parts to build the clamshell. He sent me some CAD drawings last night:

He's also done one showing how the canvas might look:

It seems like a pretty straightforward application of the TrailTop parts, his concept wouldn't be too hard to build. The hinged roof type would be fairly easy - only hinges and some prop rods or gas struts would be required.

The vertical lifting style needs some sort of mechanism for raising the roof vertically. I have no experience with clamshell tents where the roof raises vertically, so I am not familiar with the types of mechanisms they use. Anyone have any good ideas about a mechanism for a vertical roof raise?

Maybe if I get that sewing machine I've been thinking about this would be a good next project...

Pinnacle Campers

Chateau spotter

I had considered many times recently starting a thread in the pop up section asking for contributions of the different type of pop up methods that exist out there.

From RTT to unicat, from hand crank to hydraulic, if they own the product its on and can take pics of the system and give a brief description....

Maybe you should take the lead?

Btw I like where this thread is going. Wether its standalone RTT's or integrated into a tear drop/ camper shell using easy to build with components.

From RTT to unicat, from hand crank to hydraulic, if they own the product its on and can take pics of the system and give a brief description....

Maybe you should take the lead?

Btw I like where this thread is going. Wether its standalone RTT's or integrated into a tear drop/ camper shell using easy to build with components.

I haven't seen or used such a RTT, but I wonder if you could use the trailtop straight pieces in each corner as the vertical structure, perhaps with a male pin in the bottom of the upright and a female receiver in the top, and a male pin in the top half of the clam shell pointing down? You'd separate the top and bottom and insert the straight piece in each corner. I'm not sure how you'd secure the uprights or how easy that would be to do on the top of a roof/trailer.

bonomonster

Adventurer

If go into roof top tents, how about combining the two to make pop top trailers? Something like these but on your trail top trailer workups instead of a van.

Sent from my SCH-I535 using Tapatalk

Sent from my SCH-I535 using Tapatalk

bonomonster

Adventurer

Also, how about some trail top pieces to cap off the top and bottom in this diagram.... making a fabric tent to go in between would be as simple as sowing together the 4 side walls, attaching 2" wide straps of velcro to the inside edges of the trail top parts (top and bottom), and attaching 2" velcro to the top and bottom edges of the fabric side walls.

Sent from my SCH-I535 using Tapatalk

Sent from my SCH-I535 using Tapatalk

jscherb

Expedition Leader

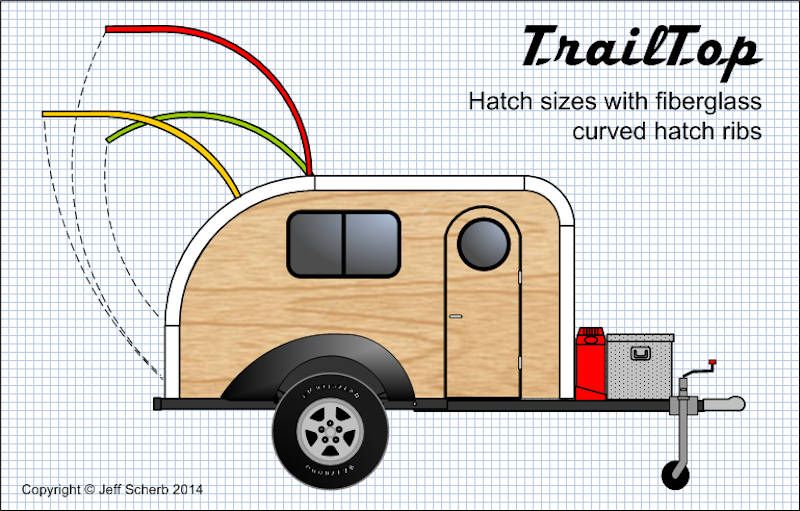

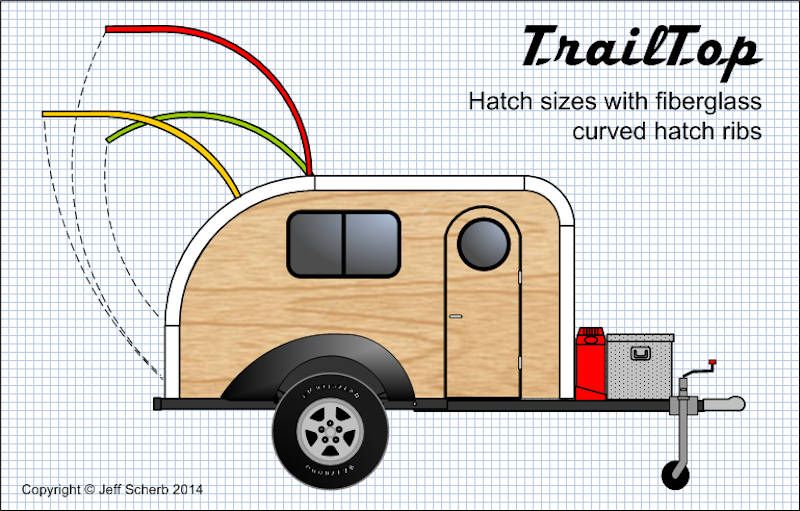

Today I'll finish up the woodworking on the mold master for the teardrop hatch ribs:

The rib master might look wide, but it's designed to make two ribs at the same time. After it's taken out of the mold the part willl be cut down the middle to result in two ribs - a left and a right.

I built a straight section at the bottom of the ribs. That's so multiple styles of galley hatch can be accommodated with the one rib mold.

These ribs will be "cut-to-length" parts, so different hatch sizes/styles can be made using the same basic ribs. In this drawing, the red hatch allows for a 3' front-to-back depth in the galley, and the hatch goes almost to the floor. The green hatch also has 3' galley depth, but only goes down to about 16" above the floor (basically where the top of a Jeep tub would be). And the yellow hatch allows for a 2' depth of galley, and goes to the floor.

Once the woodworking is finished up, I'll fill and sand this and the 12" radius skin master I made on Monday, and when that's done I'll put a nice finish on them and then they'll both be ready for making molds.

The rib master might look wide, but it's designed to make two ribs at the same time. After it's taken out of the mold the part willl be cut down the middle to result in two ribs - a left and a right.

I built a straight section at the bottom of the ribs. That's so multiple styles of galley hatch can be accommodated with the one rib mold.

These ribs will be "cut-to-length" parts, so different hatch sizes/styles can be made using the same basic ribs. In this drawing, the red hatch allows for a 3' front-to-back depth in the galley, and the hatch goes almost to the floor. The green hatch also has 3' galley depth, but only goes down to about 16" above the floor (basically where the top of a Jeep tub would be). And the yellow hatch allows for a 2' depth of galley, and goes to the floor.

Once the woodworking is finished up, I'll fill and sand this and the 12" radius skin master I made on Monday, and when that's done I'll put a nice finish on them and then they'll both be ready for making molds.

jscherb

Expedition Leader

Back to clynn85's TrailTop clamshell tent idea for a moment,

6btEx' pid='5770' dateline='1394164649 said:The vertical style uses a jack screw setup with a scissor type lift. I have been interested in building one, as the purchase price is quite steep. If the roof and floor components were available it could be the first step towards a DIY kit!

I've done a little searching to see what kind of mechanisms the commercial clamshells use.

The original Maggiolina uses a screw jack mechanism; the numbered sequence is from their website. There's a small crank on one end, and I'm told it drives the front scissor directly and the rear scissor is driven by a bicycle chain running from the front mechanism to the back.

The Maggiolina Columbus, which is hinged at one end, and their Airtop model (vertical lift) both appear to use a gas-strut assisted folding leg system:

There's a flash animation on the Autohome site showing how the roof of the gas strut model gets raised, these three frames are from that animation. Apparently you release the rear latch and the gas struts push the back up, then you release a front latch and the front goes up.

jscherb

Expedition Leader

Jeff, could you apply your design skills to the side door? I'd like to see a stout door with an openable window.

Early on in this project I thought I might make molds for a door assembly, but after a quick look around, I decided there were lots of commercial doors available, so I didn't see any point in doing yet another door that would compete with everything that's out there. Here are a few I found on eBay, for example:

It might be worthwhile to do an "upper door" for a Jeep tailgate; if a TrailTop is being built on a Jeep tub, the side-swing Jeep tailgate could be installed, and an upper door like the one on my Safari Cab hardtop could bolt right up to make a full rear "barn door":

jscherb

Expedition Leader

A variant of the hinge-up roof-top clamshell idea would be to do the hinge-up directly on a Dinoot trailer tub. The same TrailTop parts would be used for both the clamshell and the trailer top pop-up, and the same exact canvas parts and lift mechanism could also applied to a flip-up on a Dinoot tub.

Similar threads

- Replies

- 3

- Views

- 520

- Replies

- 2

- Views

- 649

- Replies

- 9

- Views

- 380

- Replies

- 9

- Views

- 2K

- Replies

- 0

- Views

- 460