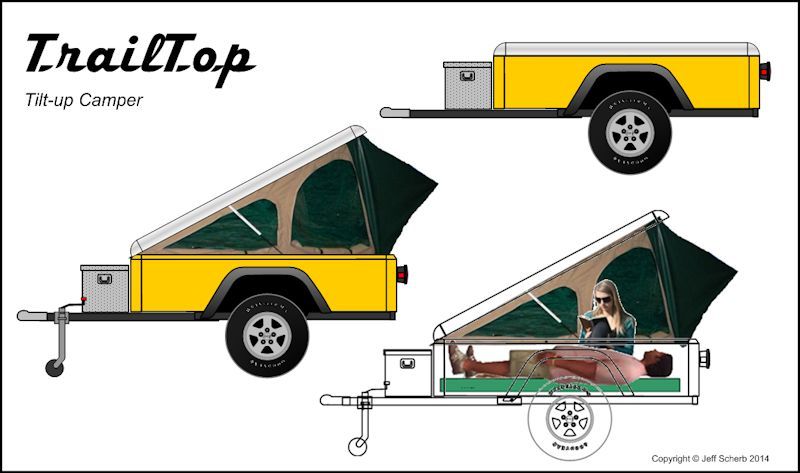

I've been busy with a few other projects so I haven't had time to begin the assembly of the TrailTop proof-of-concept #2 until now. Here's some of the assembly steps.

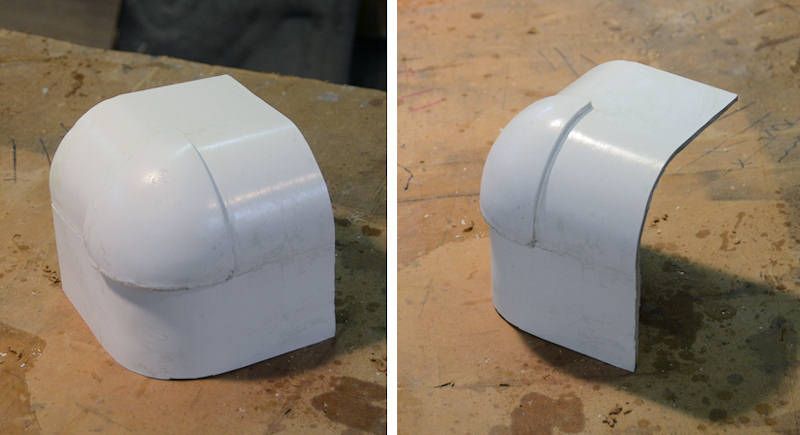

First I needed to trim the as-molded corners to remove the bottom flange. The corners have flanges on all sides so they can be used in any corner situation, but for the simple hard cover, a flange on the bottom isn't necessary. In this photo, the corner on the left is as-molded, the center one is trimmed for this application, and on the right is the scrap that was trimmed off. It's a handy scrap to hang on to because it can serve as a joiner piece in the event two straight pieces need to be joined into a longer piece. (BTW if you were building a chuck wagon top as pictured earlier today you'd leave the bottom flange in place, the vertical framing pieces would attach there).

Next, test-fitting the corner on the tub. A little bit of sanding was required on inside of the bottom where the flange was trimmed off to make the corner fit precisely.

Next I'm test-fitting a straight section so I can mark the correct length.

With the straight section cut to length, I trimmed the tabs so the straight butted perfectly to the corners. Here it is on the bench temporarily held together with clamps and masking tape:

And sitting in place on the tub for a test fit before a little final trimming for a perfect fit.

After doing a little final trimming, the parts will be ready to bond together. I'll make a second end piece identical to this one, and once that's done I can trim straight sections to the proper length to fit the sides and then bond everything together into a completed frame.