I Leak Oil

Expedition Leader

Great! It could also be a reluctance to upgrade existing, proven models. That way they don't compete with their own newer offerings. Would make sense for a 6HP motor to be more efficient all things being equal.

Why not throw the badlands 12k winch in the mix? I've used lots of electric winches over the years and the badlands has proven to be the best value. It always gets me out and it has a low amp draw. Granted it is slow but for me recovery is not a race and I prefer to take things slowly anyway. Plus it costs $300. Also, in a lot of calculations on this thread, I don't think duty cycle was factored in and a lot of the theoretical performance calculations are not as great once duty cycle kicks in.

I also question some of the ratings manufacturers use since I do not think they use any industry standard. What really makes a 12k winch a 12k winch? Is that what load it stalls at or is that the load it can safely handle or is that the load where it breaks? How is the duty cycle factored in? The weight rating seems pretty useless, at least to me. I have a 5000 kg rated PTO Werner winch and a 16k electric winch looks laughable next to it.

The other point was that most electric winches have a terrible duty cycle, including the Badlands, and that has to be taken into account, especially if you are doing amps vs. load vs time comparisons. Finally, I’ve read a lot of winch comparison articles over the years and what strikes me is how often real world testing shows completely different specs than the manufacturers specs. Also something to consider when making comparisons.

The big question of course, is how trust-worthy the numbers are, as there're no industry standards as far as I know.

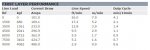

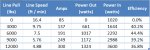

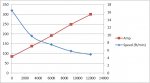

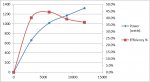

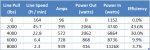

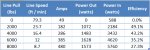

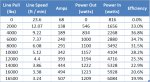

You are creating these calculation charts right? I think there is something fundamentally flawed with them. I could be wrong. But if you want to calculate the amps and watts, I would use the theoretical voltage of the running vehicle. Not 12volts. That will change the numbers a bit.. ie: 13.8 or more as you increase the load, you may even get to 14.6 volts... I'll have to test this.

So-- for example, assuming all the other actual data is accurate -- 111amps 1332 watts might actually be 1332/13.8=96.52 amps A small difference, but in the grand scheme of things it matters. In the instance of 11268 watts, the difference is more than 100amps. I just don't think you can present this all as fact, just a fun and entertaining exercise, maybe I am mistaken and I am not sure which number Amps, Watts are presented, by whom and on what basis. The numbers presented here add up to 12 volts, exactly, which is not real world.

It is highly dubious if manufacturing claims are entirely accurate, and most certainly will be biased in their favor. It is also nearly impossible to determine this data unless you actually did an actual comparison under identical conditions, electric supply, wiring, pulling conditions, etc...

As an example of this, if you run/test/own a winch and the wiring is undersized for the load, heat is created, which is going to represent energy not delivered to the winch, ie: it is lost. So one important factor maybe as or more important than any other is to properly install whichever winch you use, to use a shorter winch cable and use snatch blocks. All of which can dramatically change how your winch performs. As I mentioned before in this thread, I'm not in a particular hurry myself for various reasons when winching.

To be fair, it seems like there are several types of winch gear types. It seems like I read an article, it might have been here or somewhere else. They described winch gear type efficiency, which is where our 'consumer' grade winches are basically middle of the road compromises. Something along the line of Planetary Gear 65%, Worm Gear 40$ and Spur Gear 75%. Then of course there are the Hydraulics systems. It is an interesting and fun exercise but can be a bit overdone and subject to unscientific opinions and speculation.

Speaking of neat things you can do with a winch as Metcalf mentioned previously. I did manage to use my winch with some snatch blocks to bend down a rock slider on a defender that got seriously bent on the passenger side, that you could not open the doors. This field expedient use of the winch did the job, and they were able to wheel the rest of the weekend with use of the doors.

Admittedly, I haven't been following this too closely since page 2-3 or so, it's lining up to be an epic tug of war though.

Am I missing something?

:lurk:

Fwiw,

I had a chat with an engineer at Warn some 20 years past. (I used to be a familiar face there over the years as a contractor electrician. Very interesting place btw, but thats no different than many other factories. Excepting the brushguard assembly in the CodeAphone building seemed dodgy...)

Anyway,

He said their testing is done under as near perfect conditions of power supply, alignment, etc.

The only thing they dont 'cheat' on is super chilling a motor before tests. But they can & their testing rig has ability to adjust power & simulate real user scenario. But a formal "Proof of design" & random QA tests are done under perfect condition.