You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AND YET AGAIN: Paul and Mike Try to Build a Hard-Sided Do-It-All ADV Trailer

- Thread starter mhiscox

- Start date

mhiscox

Exp. Leader Emeritus

It's called Gatorfoam, and it's a staple of the outdoor sign industry. Look here for details:Looking good Paul! I like the look of that foam core board, does it have a common name? What sizes is it available in?

http://www.foamboardsource.com/gatorfoams--gatorfoam.html

We're using a couple of 4x8 sheets of 3/4 inch thickness. Small pieces (UPS shipable) are easy to come by, but 4 x 8 sheets involve truck delivery. Sometimes, Gatorfoam is available at art supply stores like Blick, though after carrying it for years, my local Blick no longer has it.

java

Expedition Leader

It's called Gatorfoam, and it's a staple of the outdoor sign industry. Look here for details:

http://www.foamboardsource.com/gatorfoams--gatorfoam.html

We're using a couple of 4x8 sheets of 3/4 inch thickness. Small pieces (UPS shipable) are easy to come by, but 4 x 8 sheets involve truck delivery. Sometimes, Gatorfoam is available at art supply stores like Blick, though after carrying it for years, my local Blick no longer has it.

I saw the Gatorfoam name, but at ~$120 a sheet its painful. I was wondering if there was a non brand name for the stuff.

Amazon has the 4x8 sheets shipped for $120 for the 3/4" stuff, Prime even....

mhiscox

Exp. Leader Emeritus

Used to be $102 from Amazon. It went up $18 between our first and second sheets. They have it listed as Prime, but delivery is by truck so there's about a week in transit. When you check out you pick a delivery time, and when I did it, the closest offering was a week out.I saw the Gatorfoam name, but at ~$120 a sheet its painful. I was wondering if there was a non brand name for the stuff.

Amazon has the 4x8 sheets shipped for $120 for the 3/4" stuff, Prime even....

I never found a cheaper alternative. The resin on the outside makes it weather resistant, washable, sturdy, etc. Paul's glassing it for strength and durability, but my initial plan was to try to use it with just a coat of paint. As best I know, only Gatorfoam can do that, but if you happen to find a cheaper equivalent, pass it on. (On the other hand, the equivalent amount of balsa core is about 75% more expensive.)

VanIsle_Greg

I think I need a bigger truck!

Built in insulation and it looks nice to work with too.

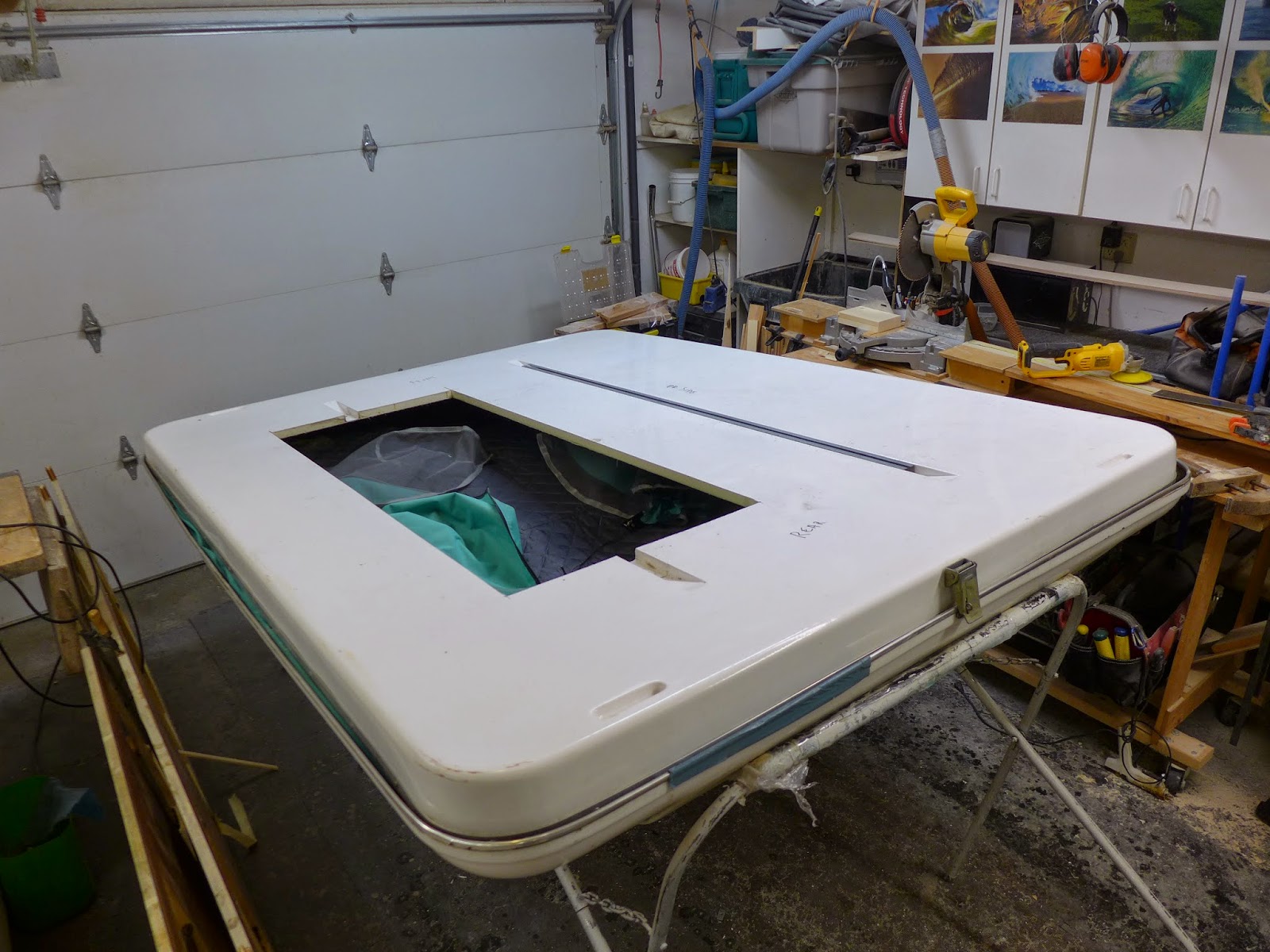

(above) The cut was made with a Festool Rail Guide Saw.... Fast and accurate...

Paul/Mike....Can you expand on entry into the RTT please. I am have been interested in this since I saw something similar with another build on different forum but I could never grasp the concept of entry with more than one person. I am also curious to the size of the opening??

PaulJensen

Custom Builder

Paul/Mike....Can you expand on entry into the RTT please. I am have been interested in this since I saw something similar with another build on different forum but I could never grasp the concept of entry with more than one person. I am also curious to the size of the opening??

Hi SC Brian...

I'll let Mike answer this one in depth, but the quick answer is sliding floor panels and fabric hinged mattress pads... Mike really thought this one through... You'll see...

Last edited:

PaulJensen

Custom Builder

11

(above) The wall panels were flipped over, the edges rounded over, sanded, then fit with fiberglass, epoxied and set aside to cure... Sound familiar...???...

(above) The other wall panel was epoxied wrapped as well...

(above) With the wall drying, the roof panel was glued up... 1/2" ply splined together with Titebond 2... Later it will get fiberglassed...

(above) The plywood panels were screwed to the worktable instead of clamping...

(above) Later after the glue set-up, the panel was cut the same as the opening in the RTT... A wood curb as glued and nailed to the ply, later to be glassed...

(above) End of the day, and it was another productive one...

(above) The wall panels were flipped over, the edges rounded over, sanded, then fit with fiberglass, epoxied and set aside to cure... Sound familiar...???...

(above) The other wall panel was epoxied wrapped as well...

(above) With the wall drying, the roof panel was glued up... 1/2" ply splined together with Titebond 2... Later it will get fiberglassed...

(above) The plywood panels were screwed to the worktable instead of clamping...

(above) Later after the glue set-up, the panel was cut the same as the opening in the RTT... A wood curb as glued and nailed to the ply, later to be glassed...

(above) End of the day, and it was another productive one...

mhiscox

Exp. Leader Emeritus

The idea with the tent beds is that the mattress gets modified to fold in two directions. When only one person is in the tent, he/she sleeps on the doubled over mattress and the opening remains open. If two people, they pull closed the panel stored under the mattress to cover the opening and climb through the hatch. This will work if the mattress is foldable like this:Hi SC Brian . . . I'll let Mike answer this one in depth, but the quick answer is sliding floor panels and fabric hinged mattress pads . . .

The overall setup (not to scale because I drew it before Paul cut the hole) looks like this:

The curbside rear quarter of the mattress is flipped forward to allow climbing up through the hatch. Once up through the hatch, the two people in the tent can sit on the streetside half long enough to flop the folded up portion back over the hatch.

Should work, though the tent will most commonly have one sleeper.

PaulJensen

Custom Builder

12

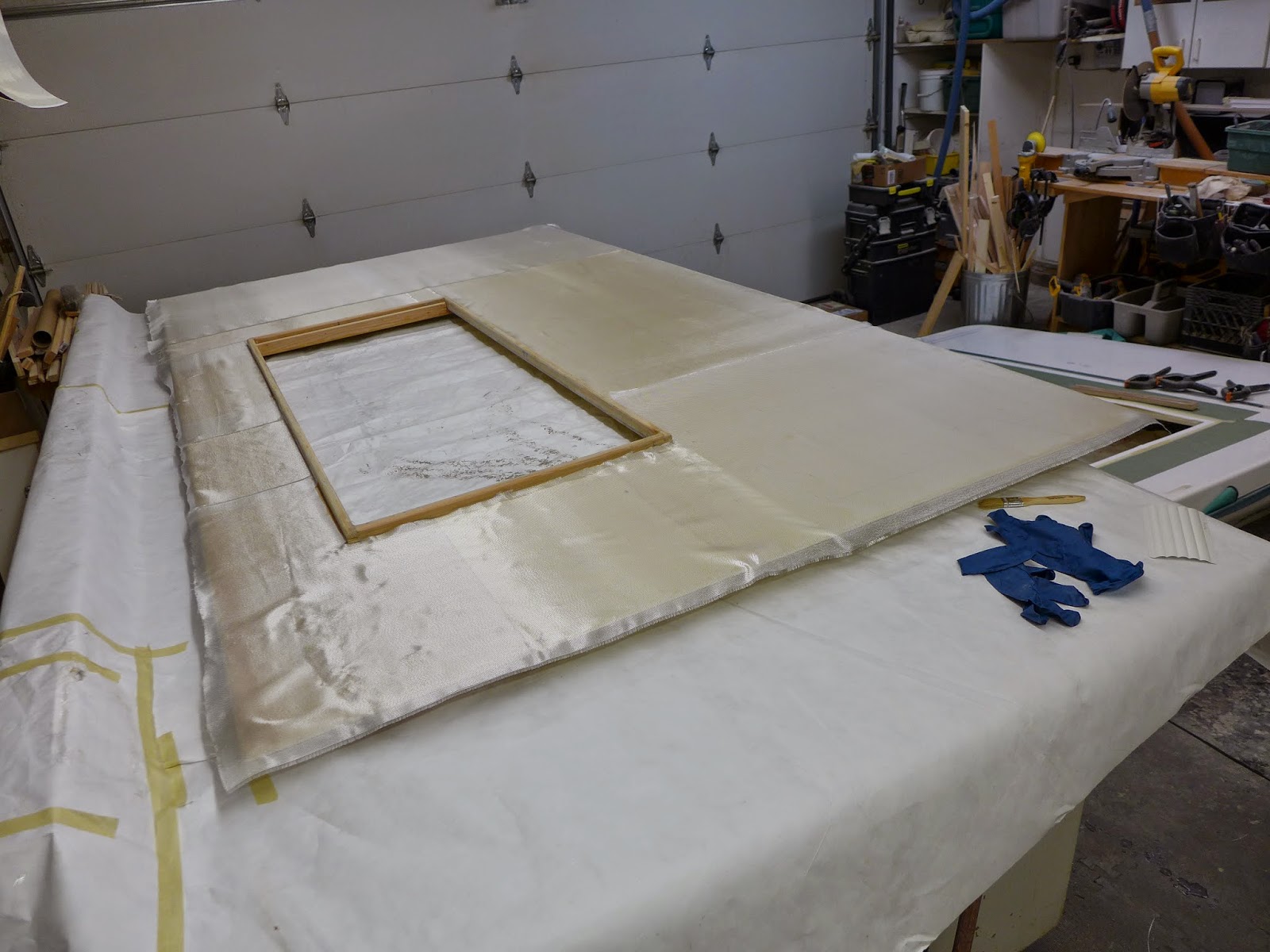

(above) With the underside of the roof deck reinforced with wood, fiberglass was laid out and epoxy was prepared to wet out the cloth...The Tyvek underneath is to act as a resin release barrier to keep the work table from being part of this build...

(above) It took about a quart of epoxy resin to do this side... Three batches kept the working time reasonable... It's a pretty big panel with a lot of glass tape reinforcements in addition to the regular flat fiberglass cloth, but that's what gives it the strength and stiffness it needs...

(above)With the glasswork curing, the better part of a day was spent getting caught up with the sanding of the earlier fiberglass work, a lot of sanding...

Next, a shallow dado was routered into the top of the 'pod' cases to set the wood strip that will be the water diverting curb, and will also be the hinge point for the walls... More fiberglassing to follow...

(above) With the underside of the roof deck reinforced with wood, fiberglass was laid out and epoxy was prepared to wet out the cloth...The Tyvek underneath is to act as a resin release barrier to keep the work table from being part of this build...

(above) It took about a quart of epoxy resin to do this side... Three batches kept the working time reasonable... It's a pretty big panel with a lot of glass tape reinforcements in addition to the regular flat fiberglass cloth, but that's what gives it the strength and stiffness it needs...

(above)With the glasswork curing, the better part of a day was spent getting caught up with the sanding of the earlier fiberglass work, a lot of sanding...

Next, a shallow dado was routered into the top of the 'pod' cases to set the wood strip that will be the water diverting curb, and will also be the hinge point for the walls... More fiberglassing to follow...

westyss

Explorer

Yeah, I was kind of faked out by that photo, too. Figure this is more like what will need to happen. I originally was going to have the sidewalls placed right at the inner edge of the pods, so that they'd be 24" wide to close to cover the trailer bed, but this model shows Paul's thought that we're better hinging the sidewalls a ways back onto the pods. Putting them, say, 6" back makes each sidewall 30", which makes the whole thing even higher but makes the interior considerably more spacious. No decision yet on that. (Though getting both sidewalls out of a single 4x8 sheet is a good thing.)

I don't know, since nothing is set in stone yet. Can you point me to your suggestion for the actuators that you'd use if you were doing this project? As I say, a lifting roof was in the first draft. Tempt us with some cheap but good actuators, since your point about it being fairly easy is a good one. Using one rated higher than needed resolves this.

I haven't looked for it yet, but I'm hopeful that there weatherstripping I can find with a big compressible bulge so that when the sides are folded in, it'll squish to make things completely tight. And I think the can find something, even if it's just a waterproof flap, to handle the joint where the sidewalls lock together. The bigger issue will be on the front and rear, I think, where there's less surface area.

Thanks for the help.

Mike, I use these actuators, http://firgelliauto.ca/400lbforce30inchstroke-p-71.html depending on the weight and stroke needed the higher weight capacity the slower they go, I find them reasonably priced and go for many cycles. The only thing negative I can say is as they age they will still lift their rated capacity but will not hold it and will slowly unwind unless propped up.

mhiscox

Exp. Leader Emeritus

Thanks for pointing me to that website. It's a good one to know about, since lots of their stuff would be useful in various camper projects.Mike, I use these actuators, http://firgelliauto.ca/400lbforce30inchstroke-p-71.html depending on the weight and stroke needed the higher weight capacity the slower they go, I find them reasonably priced and go for many cycles. The only thing negative I can say is as they age they will still lift their rated capacity but will not hold it and will slowly unwind unless propped up.

Hope all is well with you and yours.

westyss

Explorer

Thanks for pointing me to that website. It's a good one to know about, since lots of their stuff would be useful in various camper projects.

Hope all is well with you and yours.

Thanks Mike, All is well and have a good thanksgiving, we will need to get together again soon, maybe to check this trailer out!

PaulJensen

Custom Builder

13

(above) Where did I leave off...???... Oh yeah, glassing... This time the top of the plywood roof gets the treatment...Two layers where the roof top tent doesn't cover...Those areas are likely to get walked on...

(above) Twenty four ounces of resin later...

(above) The RTT floor hole was enlarged slightly, then the bottom edge was rounded over, then glassed... The spring clamps are holding down a delamination of the foam and floor... The manufacturer used polyester resin which is a poor structural adhesive compared to epoxy...

(above) Fast forward past hours of sanding and more incidental fiberglassing... I made a simple roof rack support from some 2x2's... Next, the components are loaded onto the utility bed and roughly screwed in place... Starting to look like something formidable...

(above) Now the end walls and doors can be strategized, contemplated, then built... The roof rack mock up can also be evaluated, modified then fabricated of the final material, steel...

(above) I'm liking how this is turning out...

Next, the focus will be on building the end walls...

(above) Where did I leave off...???... Oh yeah, glassing... This time the top of the plywood roof gets the treatment...Two layers where the roof top tent doesn't cover...Those areas are likely to get walked on...

(above) Twenty four ounces of resin later...

(above) The RTT floor hole was enlarged slightly, then the bottom edge was rounded over, then glassed... The spring clamps are holding down a delamination of the foam and floor... The manufacturer used polyester resin which is a poor structural adhesive compared to epoxy...

(above) Fast forward past hours of sanding and more incidental fiberglassing... I made a simple roof rack support from some 2x2's... Next, the components are loaded onto the utility bed and roughly screwed in place... Starting to look like something formidable...

(above) Now the end walls and doors can be strategized, contemplated, then built... The roof rack mock up can also be evaluated, modified then fabricated of the final material, steel...

(above) I'm liking how this is turning out...

Next, the focus will be on building the end walls...

Similar threads

- Replies

- 31

- Views

- 5K

- Replies

- 20

- Views

- 3K

- Replies

- 40

- Views

- 7K

- Replies

- 1

- Views

- 692