rayra

Expedition Leader

yeah that's a nice tank mod, really tucks up nice and high.

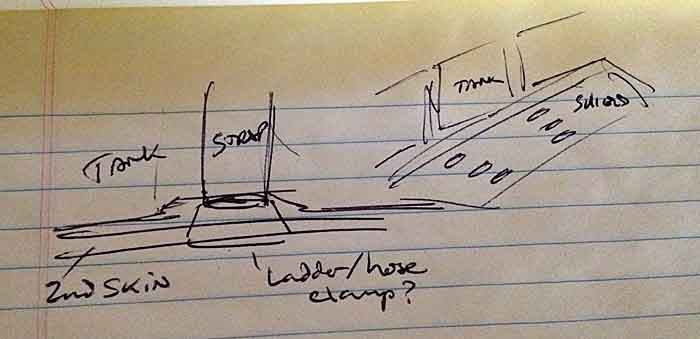

I keep looking at that exposed expanse of factory poly tank and doodling ideas for covering it with an aluminum plate. Just want to add it as a skin / double hull sort of thing. Can't figure a way to make it truly 'structural' - something you could high-center on - without a lot of tubular framing. Might just make it like the shield on the driveshaft side of the tank, just something to increase penetration resistance, close fitting. There really isn't much vertical room below the tank, it sits less than 1" above the bottom of the frame rails. Trying to figure ways to suspend a plate without it winding up shoved into the tank in a high-center situation. And I don't think there's any room to move the tank upward.

Might settle for suspending the plate from the tank straps themselves and very close to the tank, keep it above the frame rails. Turn the plate edges upward so they won't snag on anything. Few more photos and sketches and I'm on to the 'cardboard aided design' stage. Another one of my long-lead-time slow motion projects. But I post it here figuring you guys might be interested in something like that (too).

I keep looking at that exposed expanse of factory poly tank and doodling ideas for covering it with an aluminum plate. Just want to add it as a skin / double hull sort of thing. Can't figure a way to make it truly 'structural' - something you could high-center on - without a lot of tubular framing. Might just make it like the shield on the driveshaft side of the tank, just something to increase penetration resistance, close fitting. There really isn't much vertical room below the tank, it sits less than 1" above the bottom of the frame rails. Trying to figure ways to suspend a plate without it winding up shoved into the tank in a high-center situation. And I don't think there's any room to move the tank upward.

Might settle for suspending the plate from the tank straps themselves and very close to the tank, keep it above the frame rails. Turn the plate edges upward so they won't snag on anything. Few more photos and sketches and I'm on to the 'cardboard aided design' stage. Another one of my long-lead-time slow motion projects. But I post it here figuring you guys might be interested in something like that (too).