Field Report: Hackney Fuso Frame

Guys (the word guys is a gender neutral term where I grew up...

),

Thank you for the concern about our situation.

Sorry for the delay in posting on this. We are in a very low bandwidth situation down here (1 to 15 kbps upstream, and no, I am not making those numbers up, I tested it), so my ability to do anything other than deal with our situation has been very limited.

You can read some of my thoughts on our frame situation by checking out our trip thread. I literally don't have the bandwidth to open another window and put the link in here, so someone please post it to this thread.

Here's a brief history/timeline:

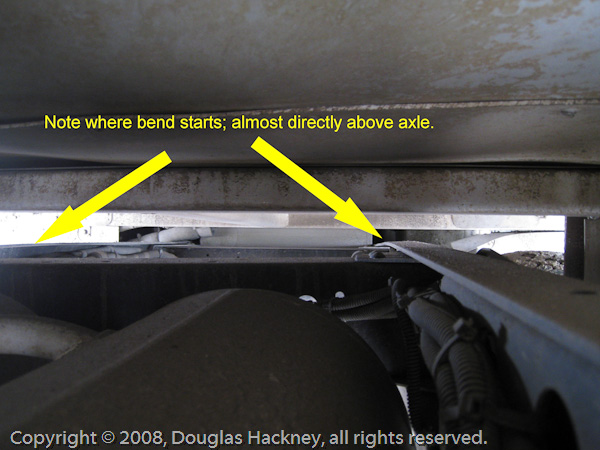

1) October 2008, we bent the frame at the rear axle line winching out a large Mercedes overland expedition vehicle. It is my opinion the bend started earlier, but we definitely hurt the Fuso badly with the winching. When we discovered the bend we parked the truck until we returned from our holiday visit to the U.S.

2) January 2009. Although we repaired/straightened the bend and installed frame reinforcements in that area as per the Fuso body builder's manual (3.7 Reinforcement of side rail FE-FG I-3-7 to 8), we believe their net effect was to move the stress forward to the next highest concentration of force: the forward spring hanger.

3) February 2009. Frame breaks on very rough road (although by no means the roughest we have been on) in Ecuador at around 12k feet. Probable cause was a huge, sharp hole along a cliff edge, sharp right hand turn, about 14k feet up in the Andes. I didn’t see it in time in the fog, rain and dark - and I emphasize very, very heavy fog. I was going about 5 to 10 mph at the time, if that helps give you an idea of how heavy the fog was. At that speed I thought I was overdriving our fog lights, which are aimed about 5 feet in front of the bumper.

The frame break happened on the driver’s side (LHD), just forward of the rear spring shackle/hanger ahead of the axle.

The frame is cracked on the passenger side (LHD) at the cross member that is one forward of the break.

Our frame was extended in two places, at the midpoint just aft of the step-down and at the tail. I believe both extensions are more rigid than the stock frame. 20/20 hindsight - we should have sleeved or reinforced the entire frame.

Our pivot frame does put stress on two sections of the frame that are relatively far apart. We experience fore/aft pitching of the pivot frame/camper due to the inherent flexibility of the Fuso frame. I agree with Chip and John (whatcharterboat) that the repeated fore/aft pitch probably weakened the stock sections of the frame over time.

At this time, our truck is in Ecuador being repaired. I am working on posting an update that details the process now. At the upstream data rates I am working with, the 1.2 MB file may take a couple of centuries to post.

About three weeks ago, while we were out on the coast of Ecuador, we decided to ship the truck back to the states and disassemble it to the point required to fix the storage boxes and the separation we were still seeing between the garage and camper.

When the frame broke we were on our way back up to the Sierra to take a trip out into the Amazon basin, then put the truck on a ship either in Columbia or Ecuador. We fell just short of making the port. If we'd had a better road or driving conditions, we might have made it. Conversely, we may have never known about the frame, but we were planning on reinforcing the entire thing anyway.

Our plan now is to ship the truck via flat rack back to the states and completely disassemble it down to the bare frame. At that point we will determine the best course of action.

We do carry a LOT of weight. Amount is unknown because every time we put the Fuso on a scale we either push the scale down through the earth's crust or the display simply flashes "tilt."

People often asked me why we didn't use an air bag suspension on the truck when we built it, including our fabricator. This situation is an example of why. Out here in the developing world you can get anything mechanical fixed. That means anything made of steel, wood, leather or fabric can be fixed. You find basically zero abandoned truck or auto chassis out here because they are still on the road or have been cannibalized to the extent there is nothing left. People out here know how to fix things and keep them rolling. A broken truck frame is just another day at the shop for these guys.

This whole thing started back in October for us, and has shaped our experiences since then. We wouldn't have made it this far without the support, advice and help of many people, including those on this forum.

I'd like to take a moment to offer public thanks for their support during this situation to:

- Fred (diplostrat) - a stalwart friend and supporter of our travels and the key person for our bent frame repair in Quito. Fred's in the Central African Republic and he hooked us up with an interpreter/fixer who saved the day for us.

- John (whatcharterboat) and the team at All Terrain Warriors - a longtime resource for us, and an endless source of engineering input, alternatives and recommendations for our Fuso.

For advice, counsel and input regarding non-Fuso chassis vehicles:

- Jay Shapiro (I can't recall his screen name and again, can't open another window to find out) - input on Ford F650 and his construction of Ecoroamer

- Charlie Aarons (same thing with the screen name) - input on Unimog chassis, etc. Always a reliable resource.

- Chip (haven) - the go-to resource for anything related to expedition campers.

Non-forum members:

- Ron Lucero, service manager, Kearny Mesa Truck Center, San Diego, CA - Ron has always been there for us, wherever we are on the planet. He's working with Fuso engineering so they can learn from this situation.

- Mark Johnson, who fabricated the Fuso.

- Jon Lee, co-Fusologist, who was my primary support (as in not losing my mind) during the build.

I'm sure I'm forgetting someone. My apologies. I'm a bit stressed right now.

Thanks again to all of you for your concern about our situation. It means a lot to us out here.

Be well,

Doug