jscherb

Expedition Leader

That's a decision the company would be making, not me (I'm just the the designerJeff, some quick thoughts:

- You show lift supports in the concept pic - would these come standard?

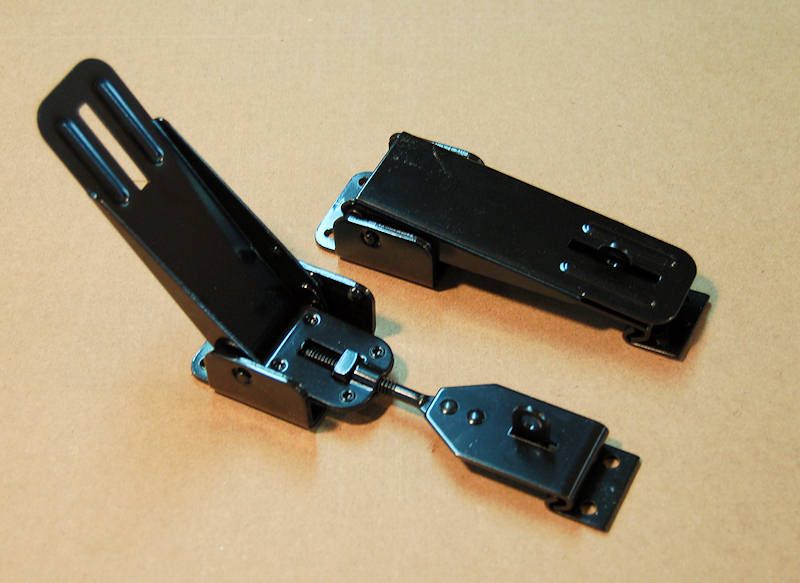

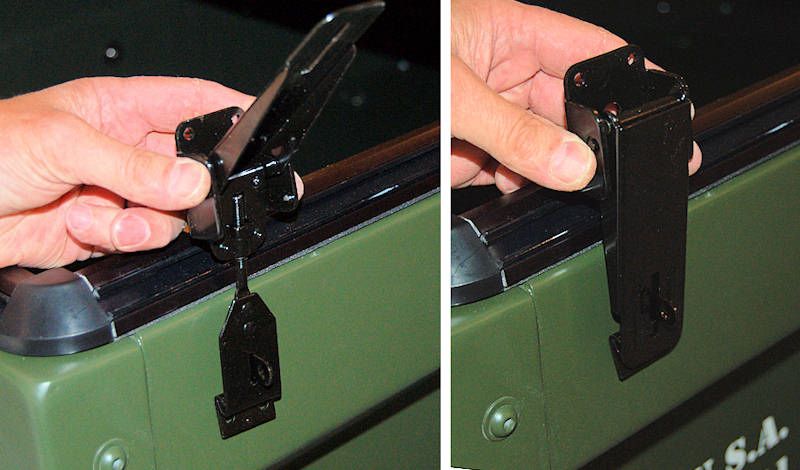

The latches I plan to use on the prototype build are lockable, in my opinion that's a requirement. I've found some affordable commercial latches that I like, I'm working on a drawing showing the latchs, I'll get it posted in the next day or two.- Would like the latches to be lockable in some way, at minimum with padlocks. Could the lid support lockable paddle latches?

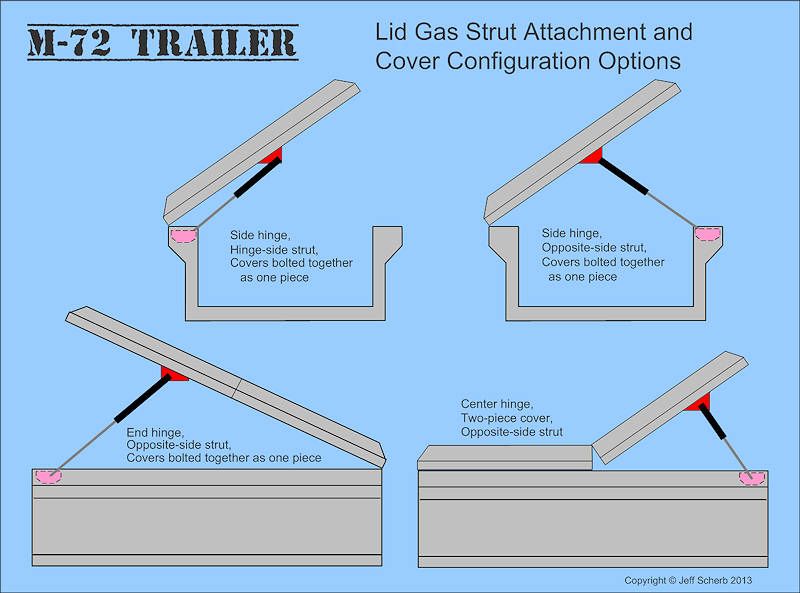

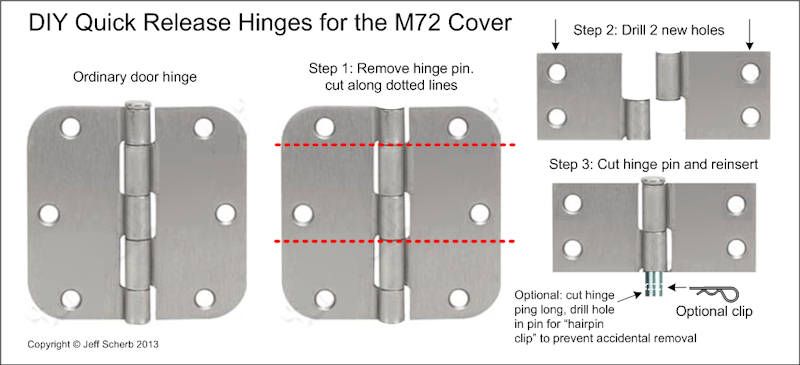

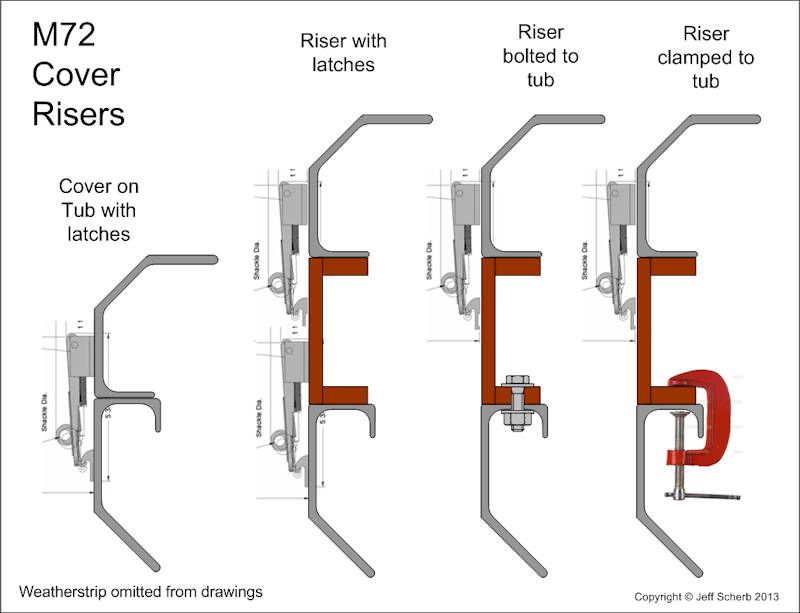

Again those are decisions the company would make. I'm designing everything so that the cover could be hinged either way, and the configuration could be changed at a later date by the owner if they decide a different configuration would suit their needs or their needs change. The way I've designed things for the prototype implementation, one single tub-side strut bracket design and one single cover-side strut bracket design will work in all configurations - center hinged, side hinged and end hinged. It may be that the design has to differ a bit if changes are made to some details of the tub design when it goes into production, so nothing is final yet.- Would the lid come in one hinge configuration but also have the hardware to adapt it to the other, or would you (or the manufacturer) see that as an order option? Or even a left as a DIY step by the customer?

I've been working on some diagrams showing different cover configurations and how the hardware would be set up, I should have something posted soon.

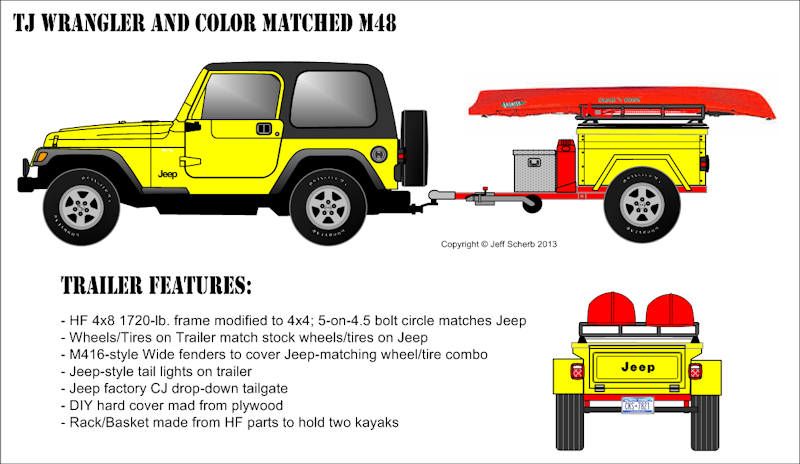

How about a tailgate with external latches? When I did the design for the Dinoot Jeep-tub trailer, I included a tailgate with external latches that can be configured as either a side-swing or a drop-down. Below is a photo of one configured as a side-swing on a Dinoot Jeep-tub trailer. It's got one external latch/lock. When configured as a drop-down, it would have two external latches/locks, one on each side. This tailgate is in production, and will fit the military tub perfectly, and will open/latch/lock without having to open the cover in either drop-down or side-swing configuration.- For tubs with a tailgate, it would be nice to not have to remove or open the lid to open the tailgate.

I can see lots of other little things like mounting lights inside the lid or ways to hang things, but these are all probably best left as DIY by customer.

Agreed. My goal with this kit is to enable lots of customization and personalized configuration by the builder.

Thanks! And thanks for the good questions. Keep 'em comingReally cool to see this come to life!