rruff

Explorer

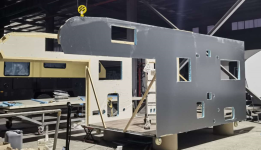

I don't think it's too technical... and people who put together that website have never impressed me with their engineering. Adding overkill in one spot while ignoring the weak link, isn't engineering.I suppose this might be too technical to discuss here.

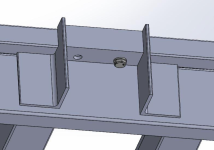

This company takes this engineering solution more seriously https://www.rvglobetrekker.com/iso-habitat-corner-mounts

Tell me what forces there would be on a habitat that 10 x 1/2" high strength steel bolts could not handle... or is it just the "foam" you are concerned about? It isn't really foam; pretty sure the fiberglass square tubes are bonded between the upper and lower skins of the composite panel.

Also note that the forces need to first overcome the weight of the habitat, since gravity tends to keep it where it is.

Also look at how huge slideins are mounted! Usually with 4 wimpy spring loaded rods that attach to the frame. And those campers are built like