For years I've had second spares for my Wranglers. I often carry them on expeditions in the event something fatal or not easily repairable happens to one of the tires on the vehicle. I don't want to be without a spare when I'm miles from the nearest road and even further from the nearest service.

When I drove my '06 Wrangler up the Dalton Highway in Alaska to Deadhorse on the Arctic Ocean, I carried three spares. One on in the normal place on the tailgate, one inside in the cargo area and one on top. I did this because in the 500 miles between Fairbanks and Deadhorse there's only one place for possible service (at 250 miles) and there wouldn't be a replacement tire there anyway. The Dalton is well known for shaking parts loose from the oilfield trucks and I did end up with a bolt in one tire, although it held air until I got back to Fairbanks.

This photo was taken at the south end of the Dalton on the way home, it was a 1000-mile round trip from here to Deadhorse and back, half of which was unpaved. The bolt is still in the tire at this point, I swapped that tire for one of the spares after a thorough car wash. As long as it was holding air there was no need to get muddy doing the swap.

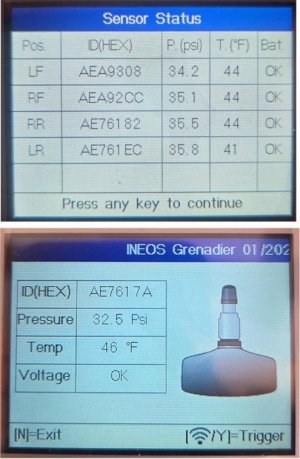

I've been looking for a second spare for the Grenadier and in the last two weeks I found a take-off wheel and a never-mounted KO2 tire, both for much less than retail.

I'll need to pick up a pressure sensor before I have the tire mounted.

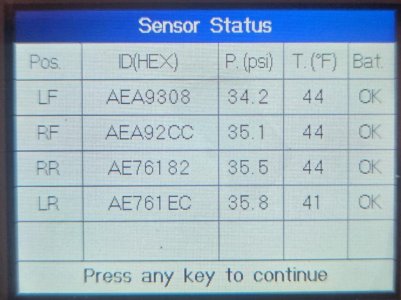

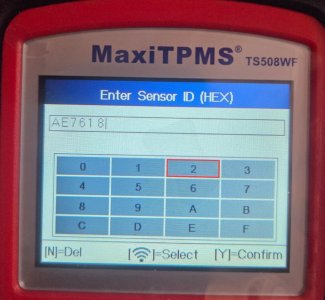

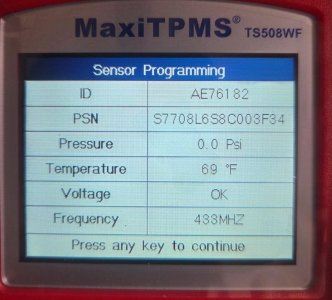

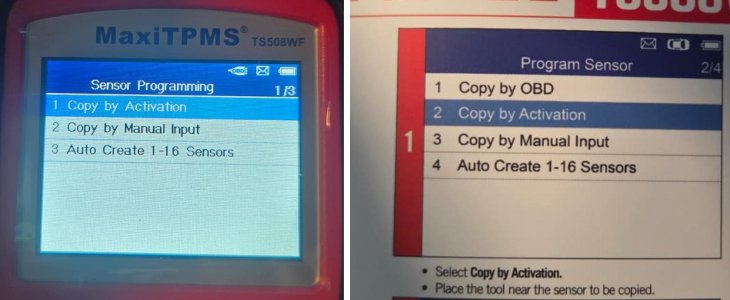

The other thing I want to get is a TPMS tool so I can program the sensors (and/or program the Grenadier). One of the annoying things about the Grenadier is the stupid TPMS system. I use the word stupid because it won't recognize when a tire has been changed - you need to either reprogram the vehicle to know about the new sensor or program the new sensor to have the same ID as the one removed. My 13 year old Wrangler will automatically recognize changes but not the Grenadier. I'm told that some people say the Grenadier will recognize one change after some miles and time, but I'm not sure I trust that.

I don't want to swap a tire on a trip and have a TPMS warning on the dash until I can get home and get to a dealer, so carrying a TPMS tool is a requirement. More on this subject when I get one.