ebrabaek

Adventurer

It is so very easy to jump to conclusions, when a break happens. Breaks always happens in one form or another. Last break I was involved in (as was thousand of others) cost Honeywell aerospace hundreds of millions, and people were armed with pitch forks, tar and feathers, but they took charge... sort of.... ha, and problem was solved.

The worst damage to be done is fling the dirt on the manufacture, before they can get a chance to look at it, and decide what to do.

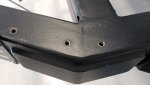

I for one, would be very interested in seeing the welds close up. I went to mine, as we have bashed that thing well, albeit at low speeds, over potholes five outings now. I observed a hair line crack on the left side. I am confident that it is in the top enamel, as it appears that the bottom flanges are NOT welded together. It does however mean that the joint is working.

Please keep us up to date of what happens.

In the mean time, I will take a look, and at the very least, weld the bottom and top flanges, as they appear to be NOT welded.

The worst damage to be done is fling the dirt on the manufacture, before they can get a chance to look at it, and decide what to do.

I for one, would be very interested in seeing the welds close up. I went to mine, as we have bashed that thing well, albeit at low speeds, over potholes five outings now. I observed a hair line crack on the left side. I am confident that it is in the top enamel, as it appears that the bottom flanges are NOT welded together. It does however mean that the joint is working.

Please keep us up to date of what happens.

In the mean time, I will take a look, and at the very least, weld the bottom and top flanges, as they appear to be NOT welded.

Last edited: