You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Trooper/Blazer I call Blooper.

- Thread starter pappawheely

- Start date

pappawheely

Autonomous4X4

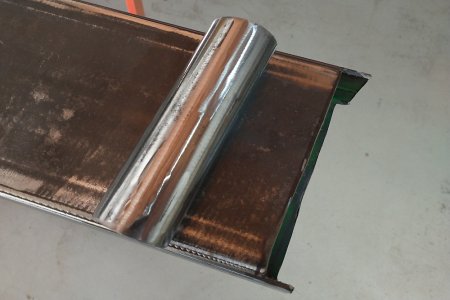

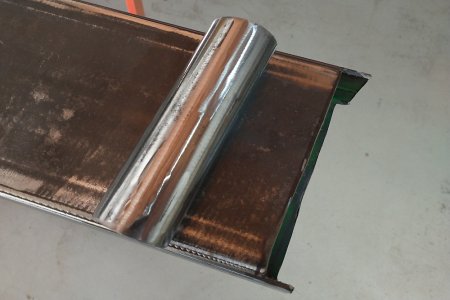

Working on the sliders. I wanted some kind of an end treatment on the main beams. I decided to notch the end on an angle. I left some material hanging out on the sides.

Then I cut some tubes at the same angle to fit inside.

I'll weld everything up and grind it all smooth. This will leave a rounded end at a 10 degree angle on the beam.

Then I cut some tubes at the same angle to fit inside.

I'll weld everything up and grind it all smooth. This will leave a rounded end at a 10 degree angle on the beam.

pappawheely

Autonomous4X4

pappawheely

Autonomous4X4

I got both sliders fabricated. Time to cut the body on the other side to match. If the passenger side rocker was not so hammered I could mount them below the rocker panel. It would have saved me hours and hours. I've watched several youtube videos on this mod. I did manage to get my welder dialed in, but everyone has trouble welding the slider to the thin sheet metal of the truck. I think I will bend a sheet metal flange that's welded to the slider, bit riveted to the body. That way I can seal up the cavity real good with silly cone and won't have to worry about water or exhaust getting in there.

I'm also starting to figure out the exoskeleton. I have some very cool plans for it. It's going to be square tube, not round. In no way is it going to be a race worthy cage, just reinforcement. I won't be going fast.

I'm also starting to figure out the exoskeleton. I have some very cool plans for it. It's going to be square tube, not round. In no way is it going to be a race worthy cage, just reinforcement. I won't be going fast.

pappawheely

Autonomous4X4

pappawheely

Autonomous4X4

I took a few days off because it was cold. When I got back to work I thought I had both the sliders done. That's when I discovered my head was up my azz. The second one I built was 4 inches too short.  It's not the end of the world. I can use it for the rear section behind each tire. I then had to build one more. I knocked it out pretty quick, but it's not identical to the other side. You can't stand on both sides at the same time so...

It's not the end of the world. I can use it for the rear section behind each tire. I then had to build one more. I knocked it out pretty quick, but it's not identical to the other side. You can't stand on both sides at the same time so...

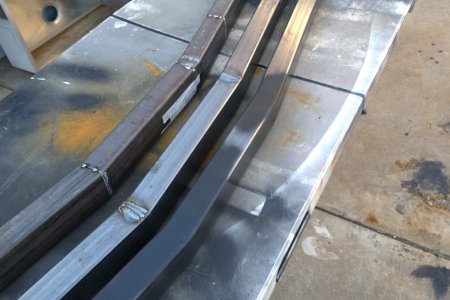

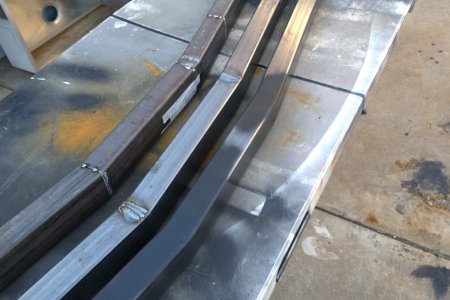

I also figured out a great way to clean up the rocker cut. I just wish I had figured it out sooner. I ordered some flanging pliers. Using the body line at the bottom of the door opening I bent the sheet metal over along that edge. It worked great so I purposely left the driver's side long when I cut it. After bending it over it leaves a real nice rolled edge that's double walled. I might even be able to weld it now.

I gave it a bend and then persuaded it with a heavy hammer. Looks nice and so easy.

I also figured out a great way to clean up the rocker cut. I just wish I had figured it out sooner. I ordered some flanging pliers. Using the body line at the bottom of the door opening I bent the sheet metal over along that edge. It worked great so I purposely left the driver's side long when I cut it. After bending it over it leaves a real nice rolled edge that's double walled. I might even be able to weld it now.

I gave it a bend and then persuaded it with a heavy hammer. Looks nice and so easy.

pappawheely

Autonomous4X4

Got some tech tips today. When you are grinding, use a respirator. Especially on older cars. They did not have as stringent rules back then, so there's no telling what you're breathing without one. Second tip. When you are grinding steel you get to a point where the flapper disc just isn't cutting anymore. Save those discs. They are perfect for removing paint without cutting into the steel; like on a frame. The other thing is if you get into some rubberized undercoating. I had some that slopped onto the frame from the factory. It just smears and absolutely ruins the disc. Since it's an old one and worn out anyways, no harm, right?

I made the decision to move the body forward on the frame one more inch before I permanently mount it. It necessitates trimming the wheel opening around the back tire, but I planned on trimming that anyways. The engine will be a little bit farther into the firewall area, no big deal at this point. The reason is to give more room in front of the engine for the radiator and ac condenser. Everything is a trade off and when you are operating with no rules, it makes it a mental game trying to think of every potential issue before you create them. Next on the list is mounting the sliders to the frame and then the sliders to the body. After that everything will be locked down. One good thing is that when I moved the body, I managed to get it lined up perfectly. It was better centered than before. As if it always wanted to go there. Spooky.

I made the decision to move the body forward on the frame one more inch before I permanently mount it. It necessitates trimming the wheel opening around the back tire, but I planned on trimming that anyways. The engine will be a little bit farther into the firewall area, no big deal at this point. The reason is to give more room in front of the engine for the radiator and ac condenser. Everything is a trade off and when you are operating with no rules, it makes it a mental game trying to think of every potential issue before you create them. Next on the list is mounting the sliders to the frame and then the sliders to the body. After that everything will be locked down. One good thing is that when I moved the body, I managed to get it lined up perfectly. It was better centered than before. As if it always wanted to go there. Spooky.

pappawheely

Autonomous4X4

pappawheely

Autonomous4X4

I didn't have to use the Rube Goldberg tool after all. The stubby drill bit on my driver worked great. It actually drilled through the frame rails well.

Here is the construction I am doing. The base plate will be welded to the frame to spread the load out. The smaller plate will be bolted to the reinforced plates on the frame. Then the 3x2, .120 wall leg will run out to the rock sliders. There will be three legs. The body will be attached to the rock sliders so the body and sliders will be mounted directly to the frame, no body mounts.

Here you can see the plate bolted to the frame. If you notice the yellow paint lines on the top of the frame. That's the one inch I moved the body forward. I painted the frame under the plates with steel-it so it doesn't rust. I can weld through it, it's designed for that. You might also see the 5th bolt head. I was originally going to do rosebud welds on all the existing holes in the base plate but this hole just happened to line up with an existing hole in the frame, so I used it to align the plate before drilling the holes in the frame. The same hole existed on the other side. Ironically, it was the same for the rear mount. It had existing holes that lined up on both sides too. It makes it so much easier not having a floor in the body. Access is great!

I had just enough material sitting around to make the legs that run out to the rock sliders. They need to be at a slight angle to fit correctly. I have to get them at the correct angle the first time or I'll have to get more material. The pressure is on.

Here is the construction I am doing. The base plate will be welded to the frame to spread the load out. The smaller plate will be bolted to the reinforced plates on the frame. Then the 3x2, .120 wall leg will run out to the rock sliders. There will be three legs. The body will be attached to the rock sliders so the body and sliders will be mounted directly to the frame, no body mounts.

Here you can see the plate bolted to the frame. If you notice the yellow paint lines on the top of the frame. That's the one inch I moved the body forward. I painted the frame under the plates with steel-it so it doesn't rust. I can weld through it, it's designed for that. You might also see the 5th bolt head. I was originally going to do rosebud welds on all the existing holes in the base plate but this hole just happened to line up with an existing hole in the frame, so I used it to align the plate before drilling the holes in the frame. The same hole existed on the other side. Ironically, it was the same for the rear mount. It had existing holes that lined up on both sides too. It makes it so much easier not having a floor in the body. Access is great!

I had just enough material sitting around to make the legs that run out to the rock sliders. They need to be at a slight angle to fit correctly. I have to get them at the correct angle the first time or I'll have to get more material. The pressure is on.

Last edited:

pappawheely

Autonomous4X4

Did a ton of welding today. Six plates welded to the frame. When it comes to stacking dimes, I'm the best as long as it's someplace nobody will ever see. Happens every time.

More, please. Your journal is an inspiring journey of ingenuity, mostly beyond me.Did a ton of welding today. Six plates welded to the frame. When it comes to stacking dimes, I'm the best as long as it's someplace nobody will ever see. Happens every time.

The insane masterpiece in-progress is especially fascinating for me since we took our stock 84 Trooper on a two-month honeymoon throughout Mexico, our fondest memories. It was an unfailing trooper indeed but also a source of constant amusement. Powered by a 1.9L single-barrel carb, the only vehicles we could pass were antique VW vans and overloaded camiones... often threatening to cut two large holes in the floor to create a Flintstones hybrid. Your Blooper is an unfolding fantasy.

Thanks

pappawheely

Autonomous4X4

I made a couple legs for the sliders, but didn't like them, so I made new ones. These will go under them to give more support. I cut them out like puzzle pieces so I could use less material. Then I tacked them together and did some clean up grinding. That's a good way to make stuff when you are building several. Tack them together so you make two at the same time. The front two are flat, the rear two are at a 5 degree angle because the frame dips down there.

I have the legs tacked together and they will hold the slider up in place.

I'll take a pie slice out of the end and bend it up to cap the ends. It will have a third leg, but I'm going to do a bunch of work I need to do first before I build that one. I'll build that one in place after I'm pretty confident I won't be lifting the body off. Now I can start on the exo cage. The plans I have are kind of wild.

I have the legs tacked together and they will hold the slider up in place.

I'll take a pie slice out of the end and bend it up to cap the ends. It will have a third leg, but I'm going to do a bunch of work I need to do first before I build that one. I'll build that one in place after I'm pretty confident I won't be lifting the body off. Now I can start on the exo cage. The plans I have are kind of wild.

pappawheely

Autonomous4X4

I tacked together a bunch of scrap to prototype the first leg of the exoskeleton. On the bottom kink I cut angles and butted it together. On the upper kink I made pie cuts with the chop saw and bent it over. Two pie cuts got me 10 degrees of bend. I'm going to use this method as it's super easy and leaves the outside edge totally smooth and uninterrupted. No reason to add my ugly welds if not needed. Notice it lines up with the body mount. What does everyone think of the rectangular tube? I think it's going to go well with all the square, straight lines on the body.

pappawheely

Autonomous4X4

Once I figured out the pie cut technique I made a passenger and driver side bar in a little over an hour. Now I need to make two more for the rear. It's another round of mental gymnastics to weld it all together in an order where I can get the back sides of everything. It fits very tight to the body. Feels good to make progress.

Similar threads

- Replies

- 0

- Views

- 224

- Replies

- 0

- Views

- 353

- Replies

- 3

- Views

- 1K

- Replies

- 8

- Views

- 990