jonnyquest

Adventurer

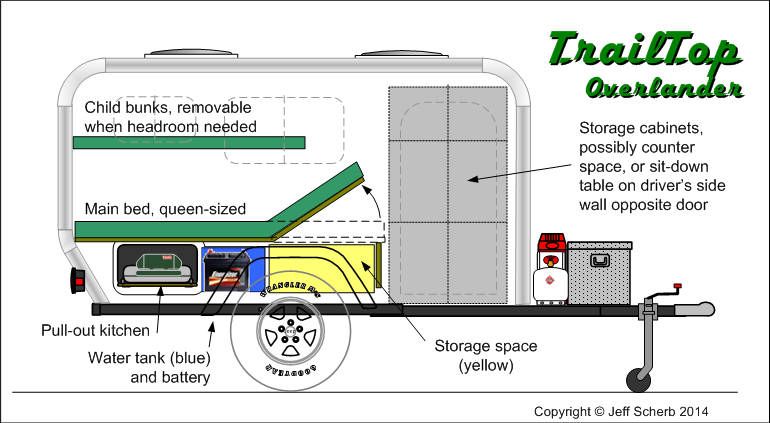

NOW you're talking! A 5 ft height would keep wind resistance down. The trailer would mostly tuck behind the tow vehicle. The 10ft length would give room for a nice bed and a sitdown table for short stays in rainy places.

If you get a chance would you mind doing an x-ray version of how you would set this up. Sleeping for two adults and three children. Storage as space is available, and the slide out kitchen that come under the awning. I have already taken your overall specs and tried to figure out a method of setting this thing up, but cant make the image in my mind appear as cleanly as you are able too.

Thanks again and please keep making these parts and testing them out. Truly innovative and exciting times for folks wanting to build THEIR perfect trailers!

Kevin

Cargo-Lite trailers are neat too. They have a window and door on each side and a ramp for the back door.

I have been jonesing for one. It would be neat with a rooftop tent.

What about angled corners and strait pieces to make slanted V noses and such. Kinda like the pic below.

**Please excuse my lack of ability to use cad programs. I had to swipe this image off the Internet to give an example of

what I'm talking about.

Interesting you posted the pickup camper drawing. From the beginning of this thread I've been thinking how they might be used for a lightweight truck camper. Very cool and I hope somebody produces these parts... and for a fair price.

Very cool and I hope somebody produces these parts... and for a fair price.

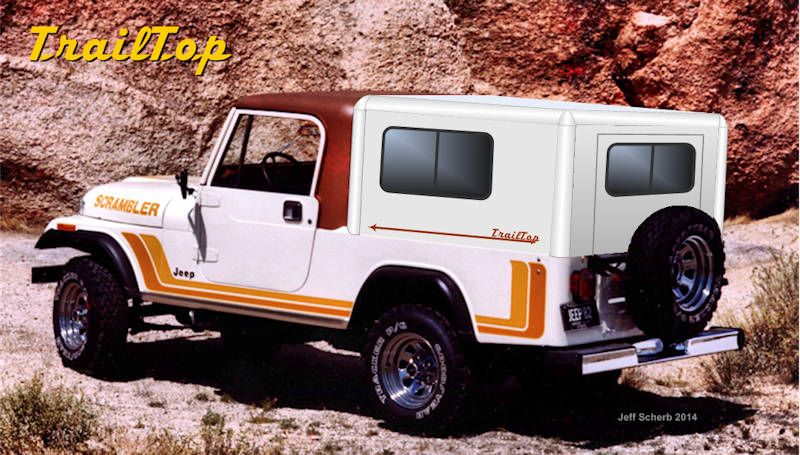

Truck campers have been part of my planning from the early stages of this project. Here's a concept I did for a Wrangler pickup:

Jeff, could this be done on an JK Unlimited that hasn't been converted to a pickup? Basically, replace the hardtop with a camper shell like above, but keeping all 4 doors.

Even better, at 5'10" I have trouble sleeping in the back with the rear seats folded down. Could we stretch this idea a few inches and use the slanted end like on the Trailtop Overlander idea?