Other commitments have been pushing the start of mold construction back a bit - I spent the last week away at the SEMA show in Las Vegas, and this coming week I'm doing a test install of the CJ Grille Kit on my LJ. When that test install is done, I should be able to start the mold construction for the new tub kit.

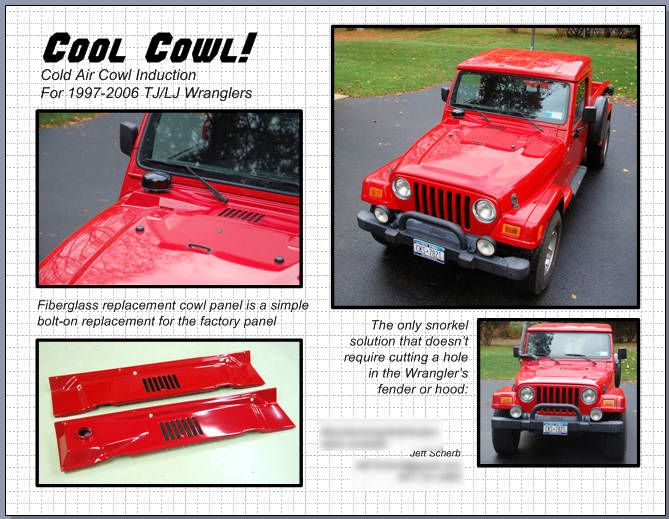

I did get sidetracked for a few weeks on a project idea that developed out of the CJ Grille Kit work - it's called the "Cool Cowl", it's a bolt-on cold-air intake cowl panel for the TJ/LJ Wrangler:

Sometimes I'll get a project idea and just have to run with it because it sounds like fun to do, and in the case of the Cool Cowl I wanted to get it done before SEMA.

But back to the military tub kit - things are moving along...

In the last week I have finalized the mold design details for the tub kit parts, and based on the design I don't expect the building of the master parts and the construction of the molds based on those parts to take too long.

I also finalized the tub reinforcement design; I've design the tub to be very strong and capable of supporting trailer-top tent platforms and other heavy loads above the tub. It also won't have the weak sides issue that military-style trailers which have tailgates cut into them often have - the tailgate opening will be very rigid.

This past week I got final pricing for the steel M416-style fenders I designed a while back, so those can now be manufactured if necessary.

While at SEMA I met with people from a company I've done business with before that manufactures diamond-plate storage boxes; I've got an idea for a new design tongue box for this trailer and I wanted to get feedback from them on the design concept.

And I've been collecting a few bits and pieces for the build of the first tub kit to come out of the molds. The molds will be able to make tubs of any length from up to 6' 6". (Actually I'm considering making the molds capable of any length tub up to 8', but I'm not sure there would ever be a need for one longer than about 6').

I plan for the first prototype to come out of the molds to be a 6' version and I plan to finish it in a military theme, including O.D. paint, military lights, military markings, etc. I've talked to my local auto paint supplier about doing color-matched O.D. single-stage paint and O.D. bed liner. The only detail of the first prototype I haven't decided on is whether to use the angular M416-style fenders or rounded M100-style fenders.

So things are moving along, I definitely plan to do the project, just finishing up a few other things first

.