Back up lights on!

Time:

Aprox 2 hours

Tools:

Basic tools required.

Since we were installing a

BajaRack Mule in place of the Con-Ferr roofrack, a new rack subframe was fabricated by Built II Beat Fabrication. The goal was to keep the rack as low as possible and as you can see it was accomplished nicely.

Here is the rack subframe:

We decided on using two

LightForce Stubby's as back-up lights. These light offer great light output and flexibility to redirect with ease. While the KJ was at the fabrication shop, we had them weld in two mounting plates for the Stubby's bases.

Here is the lights mounted to the rack:

After the lights were installed, on to my favorite...wiring. We wanted to be able to use the lights in multiple situations, and toyed with many options from an on-off-on switch to just an on-off. For ease of installation we decided to base everything off the

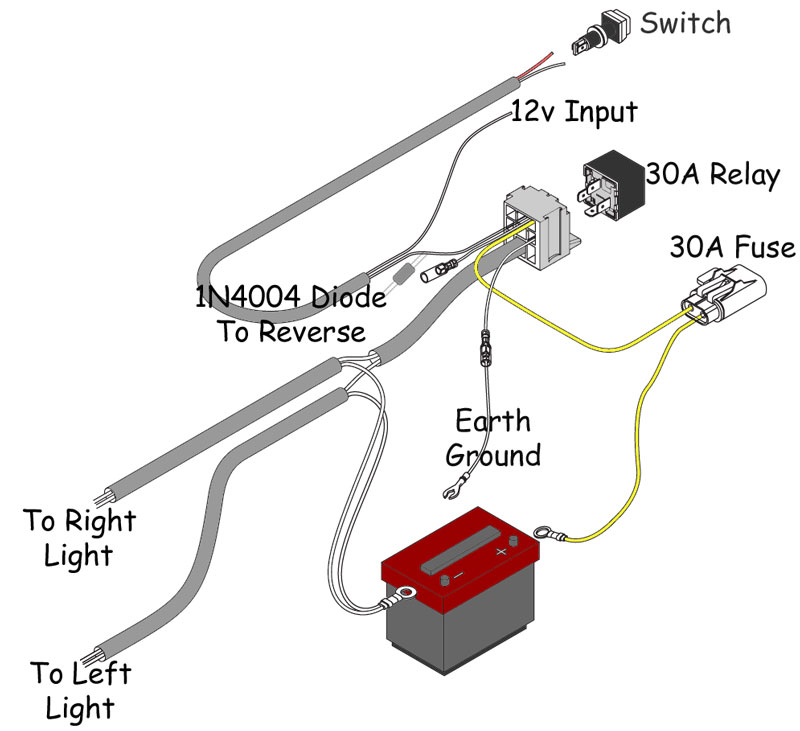

LightForce Wiring Harness, since they are very well built and the switch will match the front LightForce 170 switch on the KJ now. Below is my modified diagram of the LightForce harness:

Note:

I put a 1N4004 diode(*) in series with the OEM reverse light feed to the relay. This will isolate the OEM reverse light circuit from the aux switch, which is going to feed the same terminal on the relay. Then, when I activate the switch to turn the relay on, it will not backfeed the OEM reverse light circuit. Not that the latter is a bad thing, I just don't know how the OEM circuit works and it may not appreciate 12V being fed back into it. The effect of this isolation is that the OEM reverse lights (in the rear tail lamps) will not come on when I activate the switch.

(*) if you don't have a 1N4004 diode handy, try radio shack, a 1N4001 or 1N4002 will work as well. It's just that the 1N4004 type is near indestructible in an automotive application.

So now the big question, where to tap into the reverse lights? Looking at the FSM, I was able to dig up the following in regards to the reverse lights on 8Wa - 80 - 76:

This led me to testing the Brown wire with the green stripe on the Drivers rear tail lamp connector. This wire goes into socket 4 (highlighted yellow). It tested good when the KJ was shifted into reverse. So I traced the Brown wire with a Green stripe to the cargo compartment just under the hinge for the rear door. I figured this would be as good of a place as any to mount the relay as the wires would need to be fed up to the roof.... ah, the next decision, how to run the wires?

So after a while of pondering and looking down on the roof of the KJ, I decided it was best to just drill a hole to feed the wires through. Since I would like to keep the rack removable, we decided that trailer wire extensions would make the perfect quick disconnects. I tested the wires through a bunch of groments from the toolbox and finally landed on the smallest one I could get, a 7/16".

So now where to drill the hole? Looking down on the roof, you can see that we have a nice ding with a tad bit of rust... So I was thinking that would be a good spot, however I want the disconnects to be as hidden as possible, so it was moved a bit rear ward of where the rust spot is.

Here you can see the hole drilled:

The hole was filed smooth, and treated with some touch up paint to prevent rust. While the paint was drying it was time to start running the wiring. I had to extend both the Positive and the Negative wires. I wanted to keep the Fuse for the positive as close to the battery as possible, so I kept that the stock length and spliced between the fuse and the relay, matching the gauge wire (12g). Fuses were mounted just below the drivers side battery strut as shown below:

I like to ground off the battery when possible, so since I was already runing one cable two wouldn't kill me. So I also did the same with a 12g ground wire. Since I was going to have the relay in the rear this was also the prime opportunity to run the wires for the switch. I drilled a new hole for the switch, and in it went. I feed the positive off the already fused positve input for the Lightforce 170's.