You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How would you outfit this custom LJ?

- Thread starter jscherb

- Start date

jscherb

Expedition Leader

Can you give us a rough estimate of what the price might be?

Based on the price quote I got from the manufacturing guys, these should be very affordable. But I'm not the guy to set retail prices, heck, I'm not even an employee of the company, so it's not for me to say

jscherb

Expedition Leader

Here's a photo of the laser-cut pre-production hinges for the tailgate reinforcement.

I've got a few minor changes I want to make for the production hinges, but they'll look basically the same as these. They're done in a crinkle finish black powder coat, as are the rest of the parts of the tailgate reinforcement.

I've got a few minor changes I want to make for the production hinges, but they'll look basically the same as these. They're done in a crinkle finish black powder coat, as are the rest of the parts of the tailgate reinforcement.

Last week I had the Safari Cab LJ out on the trails at Easter Jeep Safari in Moab, I drove this one this year because I wanted to see how the modular Safari Cab stood up to a good trail thrashing.

I bet that top raised a few eyebrows. I would guess you had lots of questions asked about it.

jscherb

Expedition Leader

I bet that top raised a few eyebrows. I would guess you had lots of questions asked about it.

Yes, lots. People were stopping me in the street asking about it.

jscherb

Expedition Leader

It's been suggested that I design a Hi-Lift jack mount as an optional part of the tailgate reinforcement product - here's a conceptual view of how one might work. In this drawing, the green parts are extensions of the rails that the tailgate reinforcement hinges mount on. The blue part is a "bracket/shelf", attached to the bottom of the lower rail, for the foot of the jack to sit on. There's a wing nut (or possibly two) securing the foot of the jack to the shelf, and another one through a hole in the main bar of the jack securing it to the upper reinforcement rail.

This isn't a scale drawing, it's just a rough concept idea of where the parts would go:

I've also drawn a CB antenna mount bracket in orange because I've been asked about that too, although I'm not sure that's a good idea. Seems like it would whip around on the trail and hit the jack. Also, from an RF point of view, I'm not sure a large steel bar paralleling the antenna and likely connected to ground would be the best thing for CB reception and transmission. I'm thinking maybe I should eliminate the CB antenna mount from this plan.

Or is it not a good idea to offer a Hi-Lift mount that integrates with the tailgate reinforcement? Do people have other favorite places to store their Hi-Lift and don't want to mount it here?

Input please. Since I'm not a Hi-Lift owner/user, I don't have strong views on how this should be designed or even if it's a good idea - I'm doing this one in response to requests.

---------------------

Here's the link to the survey again for those who haven't taken it yet: Safari Cab market survey.

This isn't a scale drawing, it's just a rough concept idea of where the parts would go:

I've also drawn a CB antenna mount bracket in orange because I've been asked about that too, although I'm not sure that's a good idea. Seems like it would whip around on the trail and hit the jack. Also, from an RF point of view, I'm not sure a large steel bar paralleling the antenna and likely connected to ground would be the best thing for CB reception and transmission. I'm thinking maybe I should eliminate the CB antenna mount from this plan.

Or is it not a good idea to offer a Hi-Lift mount that integrates with the tailgate reinforcement? Do people have other favorite places to store their Hi-Lift and don't want to mount it here?

Input please. Since I'm not a Hi-Lift owner/user, I don't have strong views on how this should be designed or even if it's a good idea - I'm doing this one in response to requests.

---------------------

Here's the link to the survey again for those who haven't taken it yet: Safari Cab market survey.

Last edited:

Metcalf

Expedition Leader

I like the hinges! I have a few ideas for you....

-extend the hinges across the tailgate. If you could tie into the 'bumper' and spare tire mounts that would make the entire assembly much stronger.

-Do you have a bushing in your new hinges? A simple bushing with a trust pad on each end would make the hinge support a LOT more weight in the long run without getting loose.

-Find a way to add a support on the inside of the hinge to spread the load out to the body. The upper is pretty easy to tie into the roll bar rear mounting pad on a TJ ( and a little farther away on the LJ ). The lower is a little more difficult, but the load can be spread to the vertical portion of the wheel well tub on the 'outside' of the body.

-Eventually the hinge at the door will become the weak link. It will basically crack around the mountings. Friend and I have ran similar, but less elegant, reinforcements on TJ tailgates. I think the long term solution would be to have a replacement tailgate that had internal support that tied the hinge area to the latch area.

Just a few thoughts, love your work.

I saw your jeep parked in Moab last week but no-one was around....

-extend the hinges across the tailgate. If you could tie into the 'bumper' and spare tire mounts that would make the entire assembly much stronger.

-Do you have a bushing in your new hinges? A simple bushing with a trust pad on each end would make the hinge support a LOT more weight in the long run without getting loose.

-Find a way to add a support on the inside of the hinge to spread the load out to the body. The upper is pretty easy to tie into the roll bar rear mounting pad on a TJ ( and a little farther away on the LJ ). The lower is a little more difficult, but the load can be spread to the vertical portion of the wheel well tub on the 'outside' of the body.

-Eventually the hinge at the door will become the weak link. It will basically crack around the mountings. Friend and I have ran similar, but less elegant, reinforcements on TJ tailgates. I think the long term solution would be to have a replacement tailgate that had internal support that tied the hinge area to the latch area.

Just a few thoughts, love your work.

I saw your jeep parked in Moab last week but no-one was around....

jscherb

Expedition Leader

I've specifically designed the reinforcement so it mostly can't be seen, because I wanted to retain the stock look of the Jeep as much as possible, so you can't see much of the reinforcement part of the design in the photo I posted.I like the hinges! I have a few ideas for you....

-extend the hinges across the tailgate. If you could tie into the 'bumper' and spare tire mounts that would make the entire assembly much stronger.

The tailgate reinforcement part of this design is separate from the hinges. If all I did was run the hinges all the way across the tailgate that wouldn't provide the torsional rigidity that's needed - the goal is to prevent the tailgate from twisting. The reinforcement I've designed and built completely eliminates twisting of the tailgate, and ties in to all of the key points in the tailgate, including the tire bumper and spare tire mount points.

Another reason the reinforcement part of the design is separate from the hinges is that I intend that the hinges could be used separately without the reinforcement, if all you needed was to replaced worn or seized factory hinges, or if you just wanted to upgrade from the factory hinges to a much stronger set of hinges. Judging from the number of stiff and seized cast-aluminum factory TJ hinges I've seen, I think there should be some demand for the hinges alone as replacement/upgrade parts.

Yes, the hinge pins ride in flanged bronze bushings. There is a zerk fitting inside the hinge for greasing the bushings, and in the event of wear, the bushings can be removed and replaced to rebuild the hinges to as-new specs. And the hinge pins themselves are 3/8" diameter stainless steel, which is much larger than the factory hinge pins.-Do you have a bushing in your new hinges? A simple bushing with a trust pad on each end would make the hinge support a LOT more weight in the long run without getting loose.

I have designed inside-tub support brackets, but I haven't built them at this point. The TJ/LJ tubs have internal welded-in reinforcements for the hinges, and so far I've run over 7000 miles on- and off-road with a 73-pound spare plus the Safari Cab upper barn door attached to the tailgate (not to mention the weight of the tailgate reinforcement itself) and I'm very pleased with the structural integrity. But if internal brackets become necessary or desirable, they're an easy addition.-Find a way to add a support on the inside of the hinge to spread the load out to the body. The upper is pretty easy to tie into the roll bar rear mounting pad on a TJ ( and a little farther away on the LJ ). The lower is a little more difficult, but the load can be spread to the vertical portion of the wheel well tub on the 'outside' of the body.

I think I've accounted for those stresses in the design, but unfortunately you can't see that in the photo I posted.-Eventually the hinge at the door will become the weak link. It will basically crack around the mountings. Friend and I have ran similar, but less elegant, reinforcements on TJ tailgates. I think the long term solution would be to have a replacement tailgate that had internal support that tied the hinge area to the latch area.

Just a few thoughts, love your work.

I saw your jeep parked in Moab last week but no-one was around....

Thanks, and thanks for the thoughtful suggestions.

Ford Prefect

Expedition Leader

Yes, lots. People were stopping me in the street asking about it.I bet that top raised a few eyebrows. I would guess you had lots of questions asked about it.Last week I had the Safari Cab LJ out on the trails at Easter Jeep Safari in Moab, I drove this one this year because I wanted to see how the modular Safari Cab stood up to a good trail thrashing.

Did the GR8 tops guys bring their jeep/ Safari top out?

It would have been really great if they had theirs out at the same time, more ability for them to show case the top and perhaps drum up more business for the top.

With your hinges, etc... You just keep going don't you Jeff? Constantly coming up with ideas to improve on the jeep.

Well it looks great, I am glad that it all went off without a hitch... also, sorry that I missed you at EJS, it did not work out for me to get down there. My wife told me that I got to go to Overland Expo, and therefore could not go to EJS because we had things that we needed to do on weekends...Ah well...

Last edited:

jscherb

Expedition Leader

No, but I think they were showing it off at a 4x4 show last week in South Carolina.Did the GR8 tops guys bring their jeep/ Safari top out?

It would have been really great if they had theirs out at the same time, more ability for them to show case the top and perhaps drum up more business for the top.

I've got a long list of ideas I want to work on. I'll be doing a Hi-Lift mount to add to the tailgate reinforcement, and I've got a bunch of fiberglass projects I'm thinking about for this summer, many of which are related to the Safari Cab:With your hinges, etc... You just keep going don't you Jeff? Constantly coming up with ideas to improve on the jeep.

- Two-piece modular half cab roof for the full modular concept below

- Ambulance doors for (two vertical rear doors opening at the center)

- One-piece barn door

- Drop-down tailgate (making molds off the metal tailgate I made for the trailer but never used)

- Alpine roof

- Low-profile roof

- Half door uppers

- Safari Cab camper top for the trailer

- Barn door for factory hardtops

jscherb

Expedition Leader

Waiting patiently to plop down some cash on the Safari top with soft sides.

(OK, not so patiently)

Having spent most of the last week in Florida, and even though I'm not in the Jeep on this trip, being here for a week made me realize that if I lived in Florida, I'd almost never put a soft top down - the sun is just too intense, even in May.

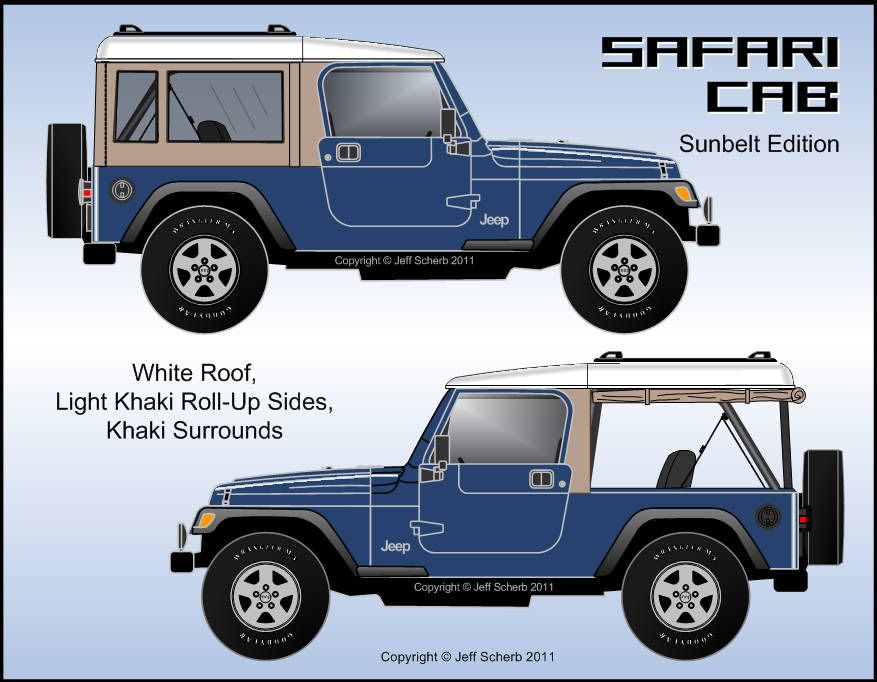

I think the configuration I'd choose for life in the sunbelt is to permanently have the hard roof on, and use the roll-up side curtains. I'd leave the side curtains rolled up all the time, only rolling them down when it rains.

This trip has me thinking the company should offer a "Sunbelt Edition" Safari Cab. It would have a white roof to reflect the sun and heat, and light khaki side curtains instead of black. Hard sides would be optional, the standard package would be the hard roof and soft sides.

Here's what the "Sunbelt Edition" theme might look like on a dark blue Jeep:

I think the optional hard sides for the Sunbelt Edition should also be finished in light khaki like the side curtains.

bob91yj

Resident **************

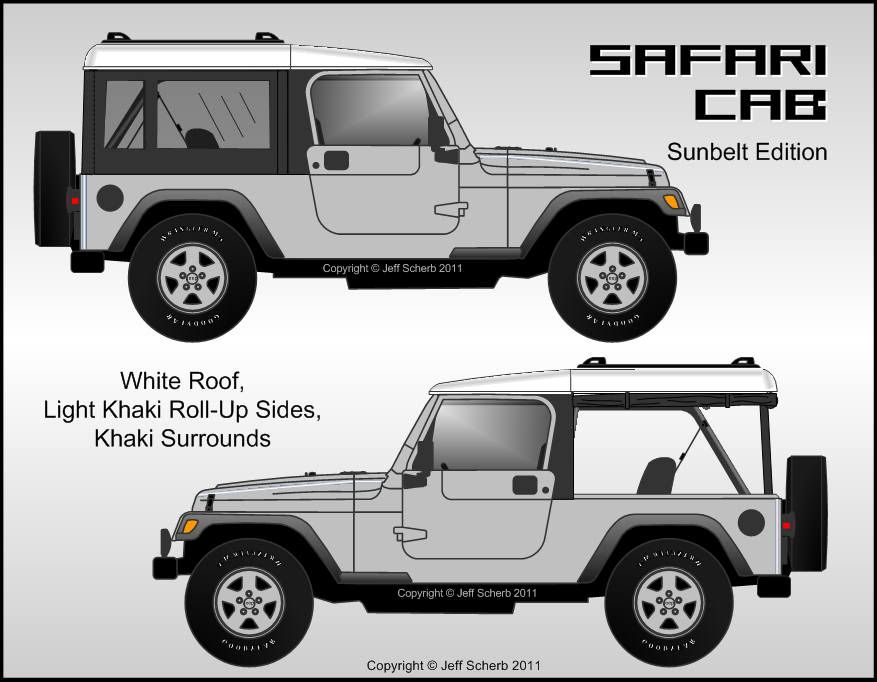

I suck on the computer, can you do that in silver paint with the factory gray soft top color on the sides and a white top?

I had a customer that painted a black JK hard top white, he claimed over 30* temperature difference on a 100* day in the Anza Borrego Desert.

Edit: I've been telling the bos...I mean my wife about this new top I was waiting to see, she finally took a look, it's got her stamp of approval!

I had a customer that painted a black JK hard top white, he claimed over 30* temperature difference on a 100* day in the Anza Borrego Desert.

Edit: I've been telling the bos...I mean my wife about this new top I was waiting to see, she finally took a look, it's got her stamp of approval!

Last edited:

jscherb

Expedition Leader

I suck on the computer, can you do that in silver paint with the factory gray soft top color on the sides and a white top?

I had a customer that painted a black JK hard top white, he claimed over 30* temperature difference on a 100* day in the Anza Borrego Desert.

Edit: I've been telling the boss...I mean my wife about this new top I was waiting to see, she finally took a look, it's got her stamp of approval!

Here you go...

Glad the boss approves.

Similar threads

- Replies

- 12

- Views

- 3K

- Replies

- 1

- Views

- 2K

- Replies

- 2

- Views

- 1K

- Replies

- 2

- Views

- 982

- Replies

- 8

- Views

- 3K