jscherb

Expedition Leader

When we're on a long trip or expedition my wife likes to bring her own food, she often cooks it at home and stores it in the fridge in the Grenadier then heats it up with an electric pot. The pot has two settings, one of which is within the range of the Grenadier's factory inverter and but the pot's high setting (600 watts) is above the capacity of the factory inverter. She says the lower setting works fast enough for her but I'm thinking about providing for a higher power inverter for her. I've got a 750-watt modified sine wave inverter I've used in the Jeeps for a few years and it works very well for her cooking and electric blanket purposes (having grown up in a hot place she's often cold). In the Jeeps I installed a connection to the auxiliary battery with an Anderson connector so the inverter could be used as needed in either Jeep.

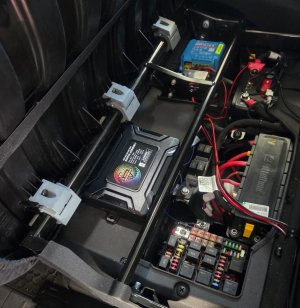

I'm thinking of installing a bulkhead-type Anderson connector in the side panel in the Grenadier's cargo area and wiring it to the Grenadier's main battery through a circuit breaker and maybe a 15a fuse on the output. Something like this:

BTW the receptacle for the factory inverter can be seen on the floor, I plugged in a short extension cord with a flat plug so it's accessible with the Jack Compartment Bag in place and the flat plug takes up no space in the bag.

I would mount the inverter on the side of the kitchen housing.

The kitchen lives in the garage and gets installed in the Grenadier as needed (it installs very quickly on the L-tracks in the floor) so it's out of the vehicle now but the inverter would fit nicely on the side of the kitchen housing, just behind the kitchen's power panel.

I'm thinking of installing a bulkhead-type Anderson connector in the side panel in the Grenadier's cargo area and wiring it to the Grenadier's main battery through a circuit breaker and maybe a 15a fuse on the output. Something like this:

BTW the receptacle for the factory inverter can be seen on the floor, I plugged in a short extension cord with a flat plug so it's accessible with the Jack Compartment Bag in place and the flat plug takes up no space in the bag.

I would mount the inverter on the side of the kitchen housing.

The kitchen lives in the garage and gets installed in the Grenadier as needed (it installs very quickly on the L-tracks in the floor) so it's out of the vehicle now but the inverter would fit nicely on the side of the kitchen housing, just behind the kitchen's power panel.

Last edited: