I live in Portugal, so I'll post from an European perspective.

I've owned 4 Land Rovers so far, a 2.5 P38 RR, a Disco II TD5 on the past and now a Disco I 300Tdi and a Defender 90 Tdi. My parents own a Disco 3 (LR3) TDV6, which I end up driving a lot.

Most of what I'll say applies to the RR Classics, Discos I, Defenders and somewhat to the Discos II.

Land Rovers, like any quirky brand, are easy to pick on.

Most of all, they have very, very good design concepts, most of their flaws are related to the used materials. In other words, awesome engineers, weak procurement/finance.

Their rear linkage design is very hard to beat for wheel travel. Even commercial models with hard springs articulate quite well.

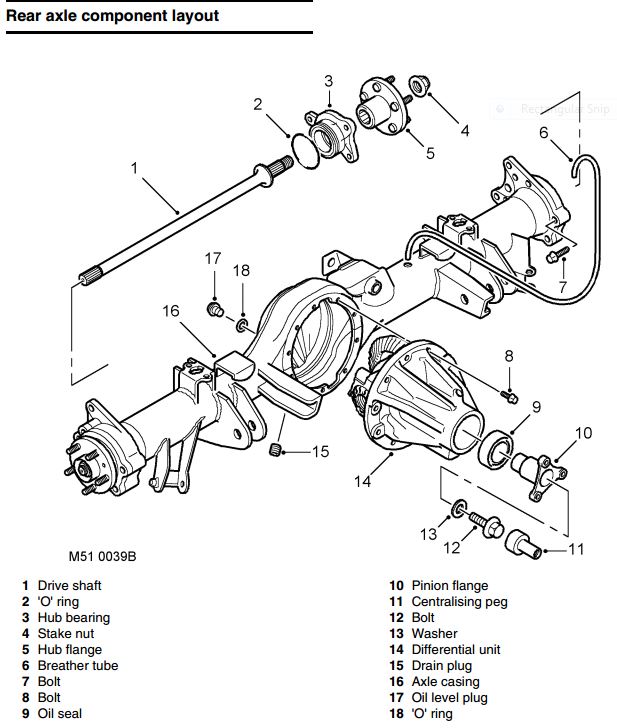

They've used full floating axles since the beginning. They'r let down by the halfshafts metallurgy, but it's an easy and cheap upgrade. The axle casings (except the diff pan) are very strong. Companies use the 130s here in EU for all sorts of weird things, typically chronically overloaded. Guess which trucks in the same fleets get bent axle casings? Yes, the Japanese ones.

Defenders have amazing payload capacities. Even my short 90 has a technical gross weight of 2700kg, weighting 1800kg. That's a 900kg payload, more than a LWB Patrol GU.

200/300Tdi engines are amazing, near a pinacle of CPUless offroad engines. Very reliable, lightweight and incredible economical. My Defender will frequently do 27 to 30 mpg(US), while the Disco do 30 to 32mpg. A 4000cm3 version would probably be perfect.

The chassis are very well designed, full boxed. They are prone to rust, but that's easily solved with correct wax or linseed oil treatment. The very big sections mean they are not s prone to cracks as other designs. Once again, looking at commercial fleets, you'll mostly see the "indestructible" Japanese pickups having chassis cracks.

The R380 is a very, very good gearbox, very reliable and durable, together with the LT230 transferbox, also very good (gear driven).

They have bolt on axle stubs and swivel balls, easy and cheap to replace vs welded ones.

They are not without problems, obviously.

Electrics are not their strength, so the less the best, making pre-TD5s diesels the best.

They only knew how to make reliable petrol engines up to the 80's.

If you'r into very hard core offroad you'll need to peg the diffs, the crownwheels are on the thin side and might jump the pinion under very heavy loads/shocks.

Interior plastics suck. My Defender is a commercial fleet model, untrimmed, but everything else has cr@ppy plastics.

They tend to rust if not protected.

You'll see that most drivetrain and suspension parts have a HD version, for a reason.

One needs to get over myths to propperly evaluate different brands.

Here in Portugal weekend warriors mostly use LRs and Nissan Patrols (Y60 and Y61s), which means a lot of rivalry between brands. LR owners really annoy Nissan guys when they say they can carry spare halfshafts and CVs in the truck, but not spare engines or gearboxes. Patrols might have nearly Dana60 strength axles but they suffer from various sorts off engine problems, cracked heads, broken chaindriven transferboxes and worn off 5th gears on the gearboxes.

Toyotas are nice but not without problems. The LC80 diesel engines have bearing problems, most of them here have been rebuild.

Swivel balls are welded to the axle and are developing an habit to break at the kinkpins, as are the swivel housings.

CVs are strong for rockcrawling, but work harden and break in weird situations. You'll see lots of reports of this happening in Africa.

Buy a Defender, RRC or a Disco I, slap a Tdi engine in it and you'll have a car for live, very capable, economical and with very long term parts availability