Quartermaster

New member

Just did similar, but I pulled out the L-track and used the existing threaded holes to bolt down for a homemade wood plate. Then picked up a fridge slide off Amazon for my Dometic CF50.

When I was shopping for my Grenadier I considered adding the factory front receiver - I use a receiver-mount winch on my three Jeeps and planned to use it with the Grenadier as well. Unfortunately the factory front receiver is only rated for moving trailers around, it's not rated for as much force as a winch can provide when getting the Grenadier unstuck.

So I ditched the idea of adding the factory receiver to the front, and decided I would need to build my own receiver as I've done for my Jeeps. I've designed and built "quick install" receivers for the front of the Jeeps which bolt in place/remove in minutes - since I only need a winch (and therefore the front receiver) when I'm on an expedition, I can install the receiver and winch just for that expedition and remove it for daily driving when I return home.

View attachment 879824

View attachment 879825

I've designed a quick install front receiver for the Grenadier and I am getting ready to build it. These are the main materials that will be used... a Reese Class IV (10,000 lb.) hitch for some pickup and a piece of 3/8"-thick steel angle:

View attachment 879826

It'll go together approximately like this - the steel angle will be cut into brackets that attach using the bumper bolts that are behind the plastic trim on either side of the center of the bumper. The Reese hitch will be cut to fit between the brackets and welded to the brackets; there will also be tabs in the back which have holes for bolts that go into factory holes on the top of the bumper into the frame. I'll have it powder coated once it's built.

View attachment 879828

Installation will be simple - remove the two plastic trim pieces (4 T-30 screws on each side), remove the 4 bumper bolts into the frame on each side, position the hitch to replace those bolts and tighten them down. Should only take a few minutes and removal will take about the same time.

I'll install it just for expeditions where I might need the winch and remove it when I get home, same as I do with the quick install receivers on the Jeeps.

Super helpful (as always). Do you recall the exact model Reese you used? Looks like they have a ton listed on their website that are probably mostly the same (although some seem to be straight and others slightly curved) - guessing the main difference has to do with the attachments on the side (which don't matter here anyway).When I was shopping for my Grenadier I considered adding the factory front receiver - I use a receiver-mount winch on my three Jeeps and planned to use it with the Grenadier as well. Unfortunately the factory front receiver is only rated for moving trailers around, it's not rated for as much force as a winch can provide when getting the Grenadier unstuck.

So I ditched the idea of adding the factory receiver to the front, and decided I would need to build my own receiver as I've done for my Jeeps. I've designed and built "quick install" receivers for the front of the Jeeps which bolt in place/remove in minutes - since I only need a winch (and therefore the front receiver) when I'm on an expedition, I can install the receiver and winch just for that expedition and remove it for daily driving when I return home.

View attachment 879824

View attachment 879825

I've designed a quick install front receiver for the Grenadier and I am getting ready to build it. These are the main materials that will be used... a Reese Class IV (10,000 lb.) hitch for some pickup and a piece of 3/8"-thick steel angle:

View attachment 879826

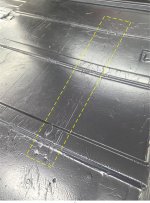

It'll go together approximately like this - the steel angle will be cut into brackets that attach using the bumper bolts that are behind the plastic trim on either side of the center of the bumper. The Reese hitch will be cut to fit between the brackets and welded to the brackets; there will also be tabs in the back which have holes for bolts that go into factory holes on the top of the bumper into the frame. I'll have it powder coated once it's built.

View attachment 879828

Installation will be simple - remove the two plastic trim pieces (4 T-30 screws on each side), remove the 4 bumper bolts into the frame on each side, position the hitch to replace those bolts and tighten them down. Should only take a few minutes and removal will take about the same time.

I'll install it just for expeditions where I might need the winch and remove it when I get home, same as I do with the quick install receivers on the Jeeps.

I'll be using a Reese 37016 for this project.Super helpful (as always). Do you recall the exact model Reese you used? Looks like they have a ton listed on their website that are probably mostly the same (although some seem to be straight and others slightly curved) - guessing the main difference has to do with the attachments on the side (which don't matter here anyway).

I use many of them but not all - some are prototypes and/or preproduction samples I'm testing.I think you may need some more storage bags..